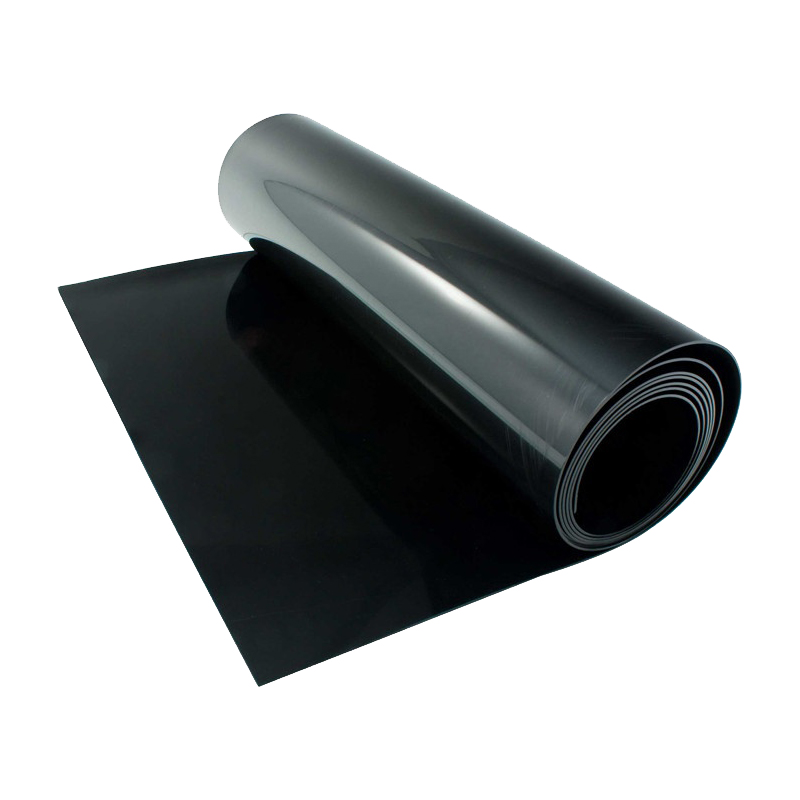

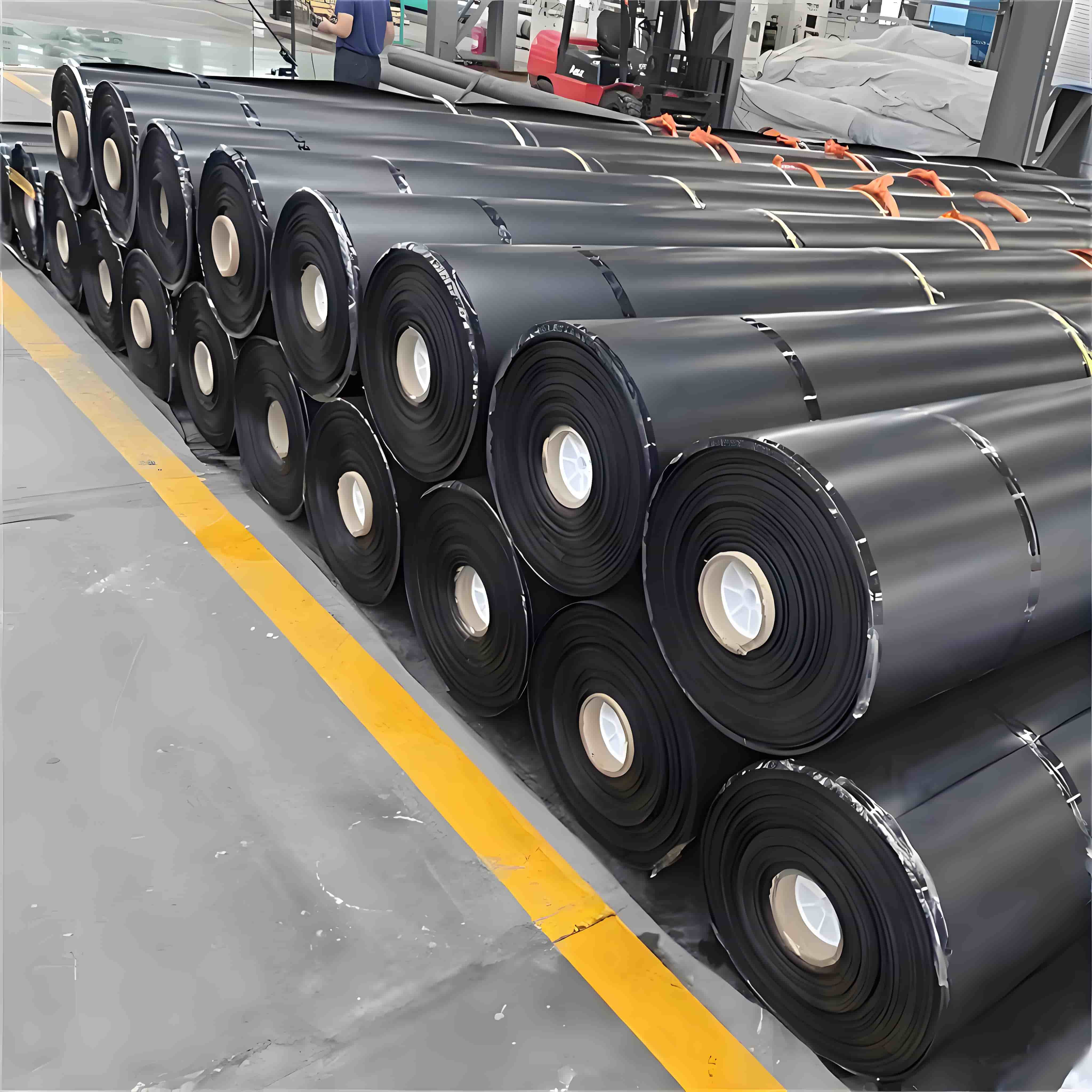

Geomembrana 40 mils

1. Excellent anti-seepage performance

Low permeability coefficient can effectively prevent the migration of liquids, gases, and pollutants.

2. Strong chemical stability

Acid and alkali resistant, corrosion-resistant, suitable for corrosive environments such as landfills and chemical wastewater tanks.

3. High durability

Good UV resistance, weather resistance, and long service life.

4. Excellent mechanical performance

High tensile strength, tear resistance, and elongation, suitable for foundation deformation.

5. Environmental protection and safety

Prevent the leakage of harmful substances and protect soil and groundwater.

Product Introduction:

Geomembrana 40 mils is a flexible waterproof barrier material made from high molecular weight polymers such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), low-density polyethylene (LDPE), etc., through high-temperature melting, extrusion, or blow molding processes. Its core functions are anti-seepage, waterproofing, isolation, and reinforcement, widely used in civil engineering, water conservancy engineering, environmental engineering, and other fields. It is an indispensable anti-seepage barrier in modern engineering.

Core Features

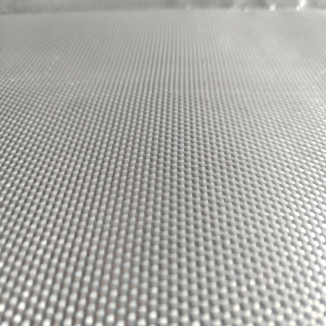

1. Excellent physical performance

High tensile strength: HDPE geomembrane has a tensile strength of ≥ 17 MPa and an elongation at break of ≥ 450%, and can withstand significant pressure and geological settlement.

Good flexibility: able to adjust with terrain undulations, reduce wrinkles and gaps, and form a continuous anti-seepage layer.

2. Strong chemical stability

Resistant to strong acid, strong alkali, and oil corrosion, suitable for chemical tanks, refinery tank liners, and other scenarios.

3. Strong adaptability

Can be used within the range of -70 ℃ to 110 ℃, suitable for extreme environments such as deserts, plateaus, and polar regions. Anti UV aging, stable performance after long-term exposure, reducing maintenance costs.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Water conservancy engineering

Reservoir and dam anti-seepage: prevent water leakage and enhance structural stability.

Canal lining: reduces water flow erosion and protects channel slopes.

River bank protection: resist water erosion and maintain ecological balance.

2. Environmental Engineering

Landfill coverage: isolate leachate to prevent pollution from spreading.

Sewage treatment facility liners: prevent sewage leakage and protect the surrounding environment.

Hazardous waste disposal site: Barrier harmful substances to ensure environmental safety.

3. Civil Engineering

Highway and railway subgrade reinforcement: reduce soil pressure and prevent foundation settlement.

Tunnel waterproofing: Form a waterproof barrier in subways and underwater tunnels to ensure operational safety.

Dock anti-seepage: prevent seawater erosion and extend the service life of facilities.

4. Agriculture and Landscape Architecture

Artificial lakes and reservoirs: maintain stable water levels and promote ecological restoration.

Irrigation system anti-seepage: reduce water resource waste and improve irrigation efficiency.

Golf course pond: Beautify the landscape while preventing soil erosion.

5. Mining and Energy

Tailings dam anti-seepage: prevent tailings slurry leakage and protect groundwater safety.

Oil storage tank liner: isolates oil products from soil to avoid pollution accidents.

Salt field crystallization pool: prevents brine leakage and improves salt production efficiency.

6. Municipal engineering

Underground engineering of subways and buildings: forming a waterproof layer to protect structural safety.

Roof gardens and planted roofs: prevent root penetration while maintaining soil moisture.

Geomembranes have become an indispensable anti-seepage material in modern engineering due to their excellent anti-seepage performance, durability, environmental friendliness, and ease of construction. From hydraulic engineering to environmental governance, from agricultural applications to mining development, geomembranes serve as a "flexible waterproof barrier" to provide reliable support for various types of projects. With the continuous advancement of technology, the performance of geomembranes will be further optimized, and their application fields will continue to expand, contributing to sustainable development.