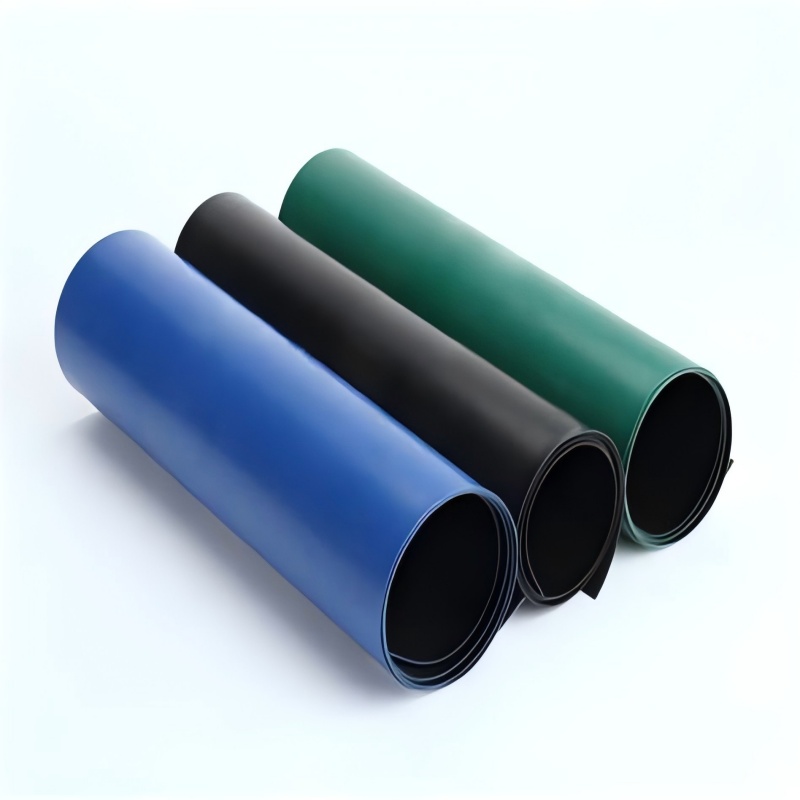

30 mil HDPE Liner

1.Water conservancy engineering:Used for anti-seepage in reservoirs and dams, water-saving in channels, and water isolation in construction cofferdams.

2.Environmental Protection Engineering:Landfill site leakage prevention, sewage treatment tank isolation, solid waste yard diffusion prevention.

3.Municipal Engineering:Artificial lakes and scenic rivers protect water, while subways and pipe galleries prevent groundwater infiltration.

4.Transportation Engineering:Highway and railway subgrade anti-seepage reinforcement, tunnel waterproof layer to block water seepage.

5.Other fields:Agricultural irrigation ponds save water, mining wastewater ponds prevent pollution, and aquaculture ponds maintain water quality.

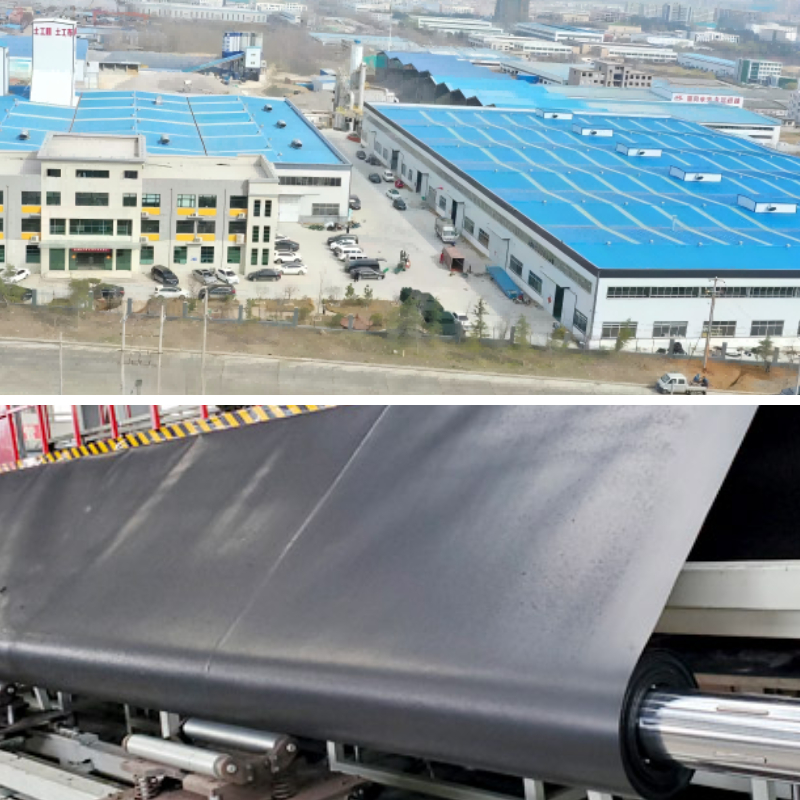

Product Introduction

I. Basic Properties

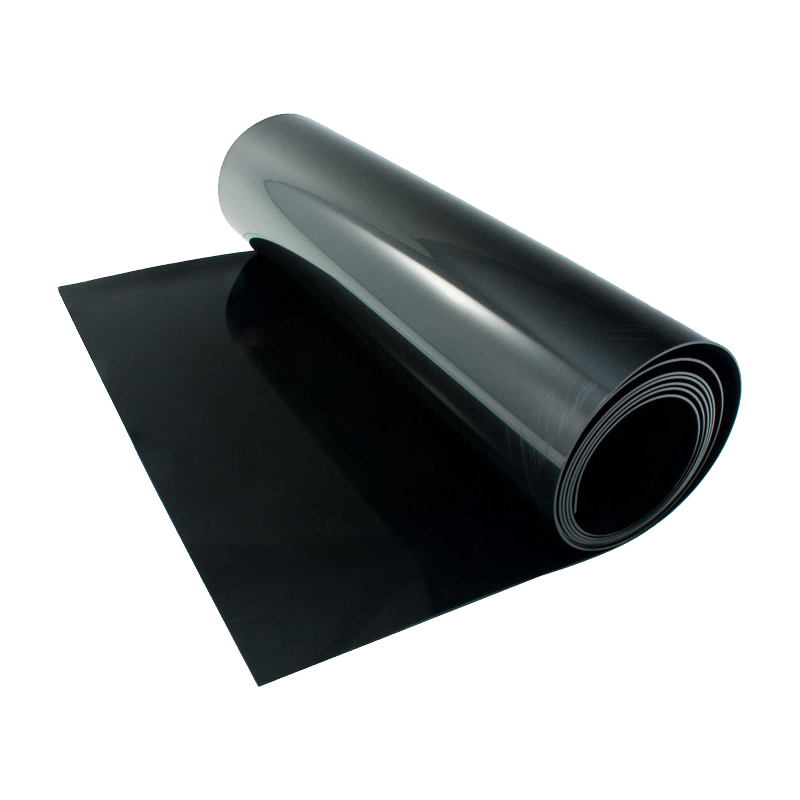

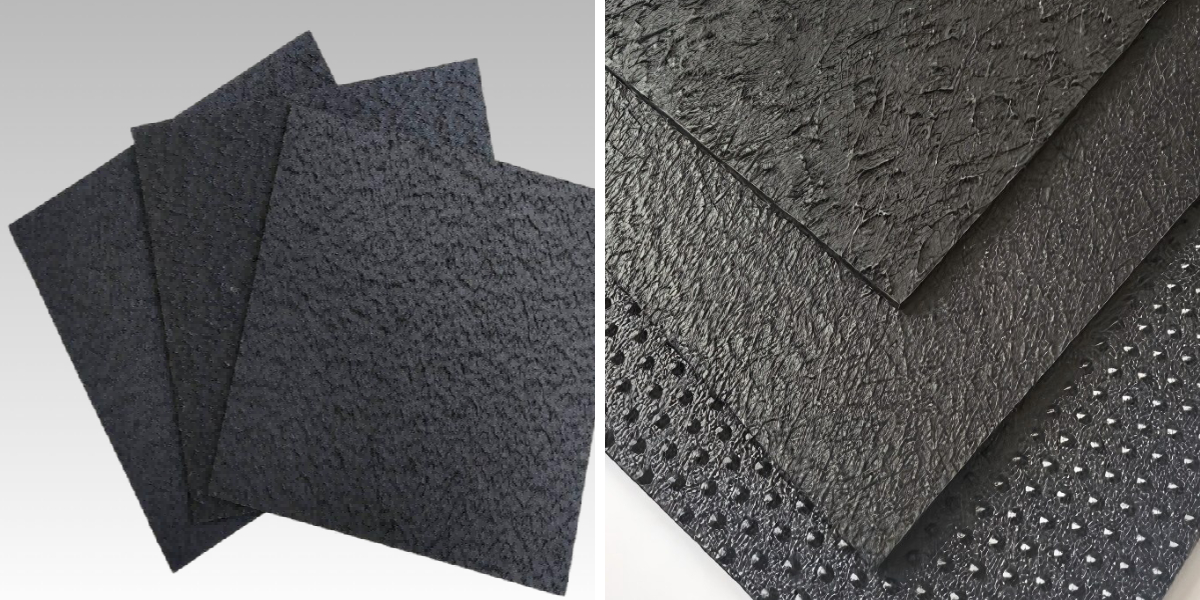

Material and Positioning: The main material is high-density polyethylene (HDPE), which is one of the mainstream categories of geomembrane. As a dedicated geomembrane liner, it can be added with UV stabilizers, antioxidants and other additives as needed to improve environmental adaptability.

Core Specifications: Thickness 30 mil (1 mil = 0.001 inch, converted to 0.762mm), width 2-8 meters and length 50-200 meters/roll can be customized to meet geomembrane installation needs of different scales; excellent physical properties, tensile strength ≥20MPa, elongation at break ≥600%, meeting the bending and stretching requirements during installation.

Environmental Adaptability: Resistant to acid, alkali, salt spray and weak organic solvents, with stable performance in environments with pH 2-13. It can be directly installed on the surface of various substrates such as soil, sand and gravel, and concrete, adapting to complex engineering environments.

II. Core Functions

Core Anti-seepage of Geomembrane: After being installed as a geomembrane liner, it forms a complete anti-seepage barrier relying on the dense molecular structure of HDPE, blocks liquid and gas penetration channels, and effectively solves leakage problems in scenarios such as water storage tanks and landfills.

Water and Soil Isolation and Protection: Through standardized geomembrane installation construction, an isolation layer is formed in projects such as landfills, tailings ponds, and artificial lakes to prevent pollutants from seeping into soil/groundwater or avoid water resource seepage and loss, realizing ecological protection.

Structural Assistance After Installation: After installation, it can disperse the pressure of upper loads on the foundation, assist in improving the stability of soft soil foundations, and at the same time reduce the damage to the geomembrane liner itself caused by foundation settlement, ensuring the long-term effectiveness of the anti-seepage system.

III. Main Features

Strong Installation Adaptability: Excellent material flexibility, can be bent and folded, convenient for transportation and on-site geomembrane installation, especially suitable for installation operations in complex terrain; supports thermal wedge welding/hot air welding, and the weld strength can reach more than 90% of the base material strength, ensuring the integrity of the anti-seepage system after installation.

Cost-Effective: As a medium-thickness geomembrane liner, it balances anti-seepage performance with procurement and installation costs, and is the preferred geomembrane category for small and medium-sized anti-seepage projects (such as small water storage tanks, municipal landfills, and small mining yards).

Long-Term Durability: The service life is 10-15 years for outdoor installation and more than 20 years for buried installation (without ultraviolet radiation), resistant to microbial erosion and not easy to be decomposed by soil bacteria; and the material is recyclable, meeting the environmental protection requirements for geomembrane materials in green projects.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

Environmental protection field: Used for anti-seepage of leachate in small and medium-sized landfills, anti-seepage of sewage/sludge treatment pools, and anti-seepage of hazardous waste temporary storage warehouses to block pollutants from infiltrating into soil and groundwater.

Water conservancy and landscape field: Laid in artificial lakes, ponds, water features, small agricultural reservoirs, and irrigation canals to reduce water leakage, adapt to terrain undulations, and facilitate construction. Geotechnical construction field: Used as an anti-seepage isolation layer for highway and railway subgrades to prevent groundwater from eroding the subgrades; also can be used for water insulation on the roof of underground garages, and cooperate with drainage boards to realize the integration of anti-seepage and drainage.

Mining field: Covering small tailings ponds and ore heap leaching ponds, resistant to slurry corrosion, and avoiding leakage to pollute the surrounding environment.

In summary, 30 mil HDPE Liner, with its high cost performance, stable anti-seepage performance and adaptability to multiple scenarios, has become the preferred material for low and medium-intensity anti-seepage projects in environmental protection, water conservancy, geotechnical construction, mining and other fields. Its characteristics of simple construction, weather resistance and corrosion resistance can not only effectively reduce project costs, but also ensure the long-term stable operation of the anti-seepage system, providing an economical and efficient solution for various anti-seepage projects.