Geotextile Fabric for Retaining Walls

1. Enhance structural stability: It can effectively disperse soil pressure, reduce deformation caused by uneven stress on the wall, improve the overall bearing capacity of the retaining wall, and extend its service life.

2. Corrosion resistance and durability: It has excellent acid and alkali resistance, UV resistance, and is not easily aged in complex soil and climate environments, and can maintain stable performance for a long time.

3. Excellent permeability: allowing water to penetrate through the fabric, avoiding additional pressure caused by water accumulation behind the wall, reducing the risk of soil erosion, and maintaining the natural balance of the soil.

4. Convenient and efficient construction: The material is lightweight, easy to cut and lay, can adapt to different terrains and construction requirements, shorten the construction period, and reduce labor costs.

Products Introduction:

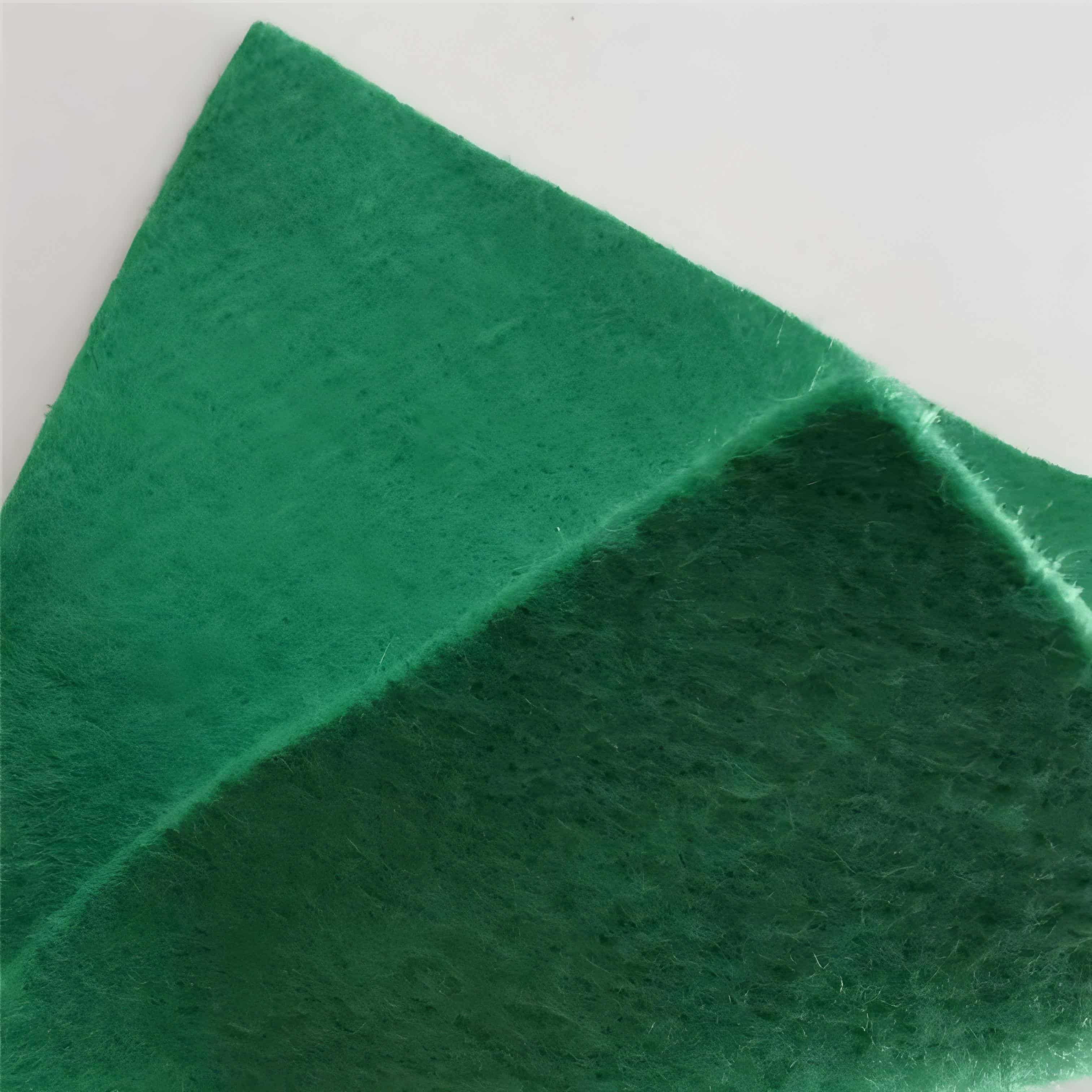

Geotextile Fabric for Retaining Walls is a high-performance synthetic material designed specifically for retaining wall engineering, made from polymer fibers such as polyester and polypropylene through needle punching, weaving, or bonding processes. It combines strength and flexibility, and can play multiple roles such as reinforcement, protection, and drainage in retaining wall structures. It is a key material for improving the stability and durability of retaining walls in modern geotechnical engineering. Compared with traditional protective materials, this geotextile has significant advantages in adapting to complex terrain, resisting environmental erosion, and reducing engineering costs, and has become the preferred auxiliary material for various retaining wall projects.

Product Features:

1. Structural reinforcement: The fiber interwoven structure endows it with high tensile strength and tear strength, which can effectively disperse the lateral soil pressure borne by the retaining wall, reduce cracks or tilting caused by uneven stress on the wall, and fundamentally improve structural stability.

2. Weather resistance and corrosion resistance: It has excellent acid and alkali resistance, oxidation resistance, and UV resistance, and can adapt to various harsh environments such as saline alkali land, humid soil, high temperature exposure, etc. Long term use is not easy to cause aging and brittleness, and the service life can reach decades.

3. Efficient drainage: The special porous structure allows water to quickly penetrate and be discharged, avoiding excessive static water pressure caused by accumulated water in the soil behind the wall, while reducing soil erosion caused by rainwater erosion, and maintaining the natural hydrological balance of the soil around the retaining wall.

4. Construction adaptability: The material is lightweight and flexible, and can be flexibly cut according to the shape (such as straight or curved) and size of the retaining wall. The laying process is simple and efficient, without the need for complex equipment, which can significantly shorten the construction period and reduce labor and equipment costs.

5. Environmental compatibility: Made of environmentally friendly polymer materials with stable chemical properties, it will not cause pollution to soil and groundwater, and meets the green environmental protection requirements of modern engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Municipal engineering: Suitable for retaining walls on both sides of urban roads, riverbank retaining walls, etc., it can resist the pressure caused by vehicle loads and water flow impacts, ensuring the safety of municipal facilities.

2. Highway and Railway Engineering: Widely used in highway slope retaining walls and railway embankment retaining walls, it can reduce the impact of roadbed settlement on the walls and adapt to the long-term effects of traffic loads.

3. Water conservancy engineering: used in scenarios such as reservoir embankment retaining walls, channel anti-seepage retaining walls, etc., to reduce water erosion on the walls through drainage functions and improve the durability of water conservancy structures.

4. Mines and industrial sites: In the treatment of mine slopes and the construction of retaining walls in industrial plant areas, they can resist the pressure generated by ore accumulation or industrial material storage, while also dealing with the complex soil environment in mining areas.

5. Civil buildings: can be used for community landscape retaining walls, private garden retaining walls, etc., balancing structural stability and ecological aesthetics, meeting the practical and environmental protection needs of small-scale projects.

Geotextile Fabric for Retaining Walls has become the core auxiliary material for retaining wall engineering due to its comprehensive performance of "enhancement+protection+drainage". It solves the problem of structural stability by dispersing pressure, adapts to diverse environments with weather resistance and corrosion resistance, maintains soil hydrological balance with drainage function, and reduces engineering costs and environmental impact with convenient construction and environmental protection properties. Whether it is a large-scale municipal, transportation engineering, or small-scale civil project, this geotextile can extend the service life of retaining walls and reduce maintenance costs through targeted performance, making it an efficient solution to improve the quality of retaining wall engineering.