HDPE Landfill Liner

1. Excellent tensile strength: The material itself has good ductility, can withstand the tensile force generated by foundation settlement, is not easy to break, and ensures the integrity of the engineering structure.

2. Environmentally friendly and reliable: non-toxic and harmless raw materials are selected, and harmful substances will not be released during construction and use, which meets the requirements of environmental engineering and is environmentally friendly.

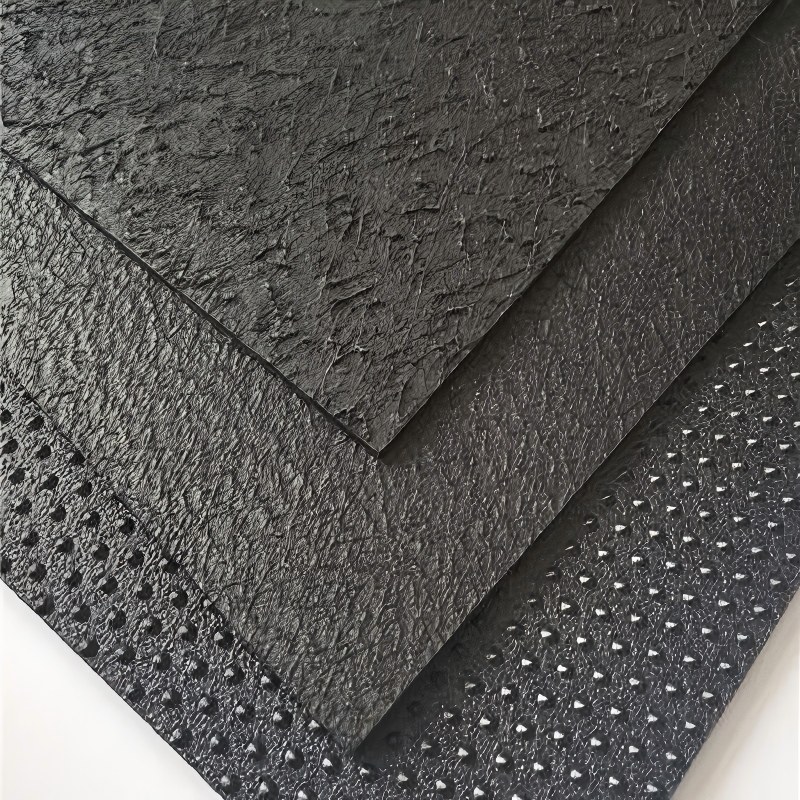

3. Strong puncture resistance: The surface is tough and can resist the puncture of sharp objects, adapt to construction environments containing impurities such as gravel, and reduce the risk of leakage caused by external damage.

4. Wide adaptability: In addition to common water conservancy and municipal engineering, it can also be applied to various scenarios such as landfill sites, artificial lakes, agricultural irrigation, etc., with a very wide range of applications.

Products Introduction:

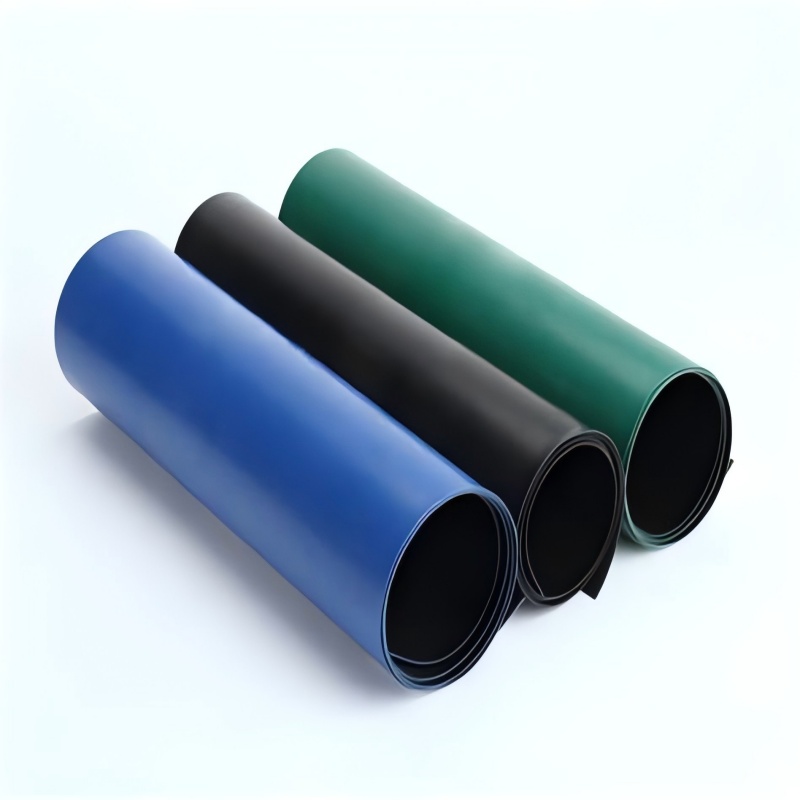

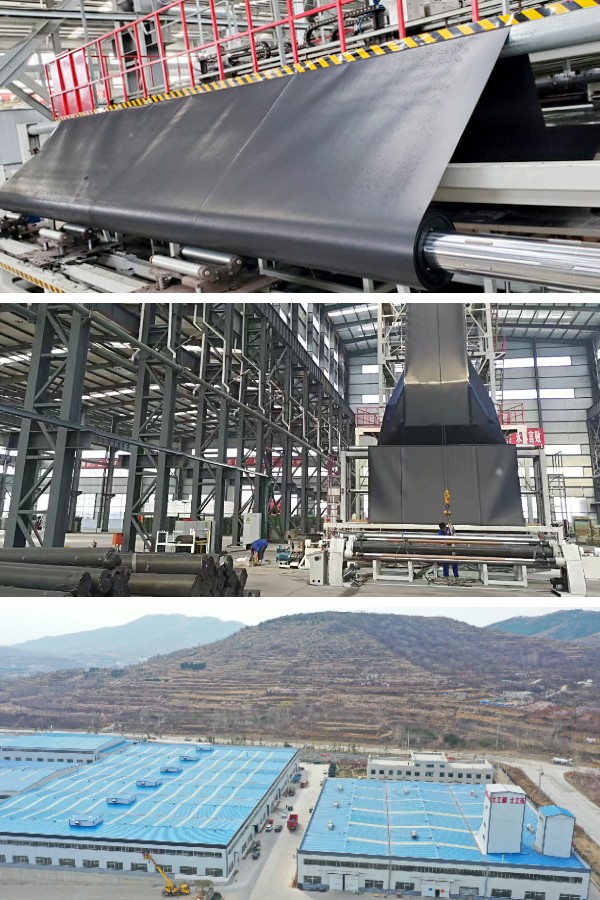

HDPE Landfill Liner geomembrane is a type of anti-seepage material mainly made of high-density polyethylene through special processing techniques. It combines the stability of high-density polyethylene material with the anti-seepage characteristics of geomembrane, and is a key material in projects such as landfills that require extremely high anti-seepage requirements. This product undergoes strict quality control during the production process to ensure that its physical and chemical properties meet relevant standards, providing long-term and reliable anti-seepage protection for the project.

Product Features:

1. Excellent anti-seepage performance

The structural design of high-density polyethylene molecules tightly arranged, combined with the introduction of nanoscale anti-seepage coatings in production, has achieved a nearly "zero permeability" anti-seepage effect. Actual test data shows that its permeability coefficient is much lower than that of traditional anti-seepage materials (such as clay anti-seepage layer, which usually has a permeability coefficient of 1 × 10 ⁻⁷ cm/s), and can completely block the migration of heavy metal ions (such as lead and cadmium) and organic pollutants (such as benzene derivatives) from garbage leachate to soil and groundwater. Even in environments with temperature changes (-60 ℃ to 60 ℃) or pressure fluctuations (0-0.5MPa), the anti-seepage performance remains stable.

2. Strong mechanical properties

Relying on the polymer chain structure of high-density polyethylene, the product has outstanding tensile and impact resistance. In both horizontal and vertical tensile tests, the elongation at break exceeded 700%, and it can withstand uneven settlement caused by garbage accumulation in the landfill site (with a maximum allowable settlement of 5%) without breaking. At the same time, its puncture resistance strength is over 3.2kN/m, which can resist the puncture of sharp objects such as gravel and steel bars in landfills. Combined with specialized welding technology (joint strength ≥ 80% of the base material strength), it can form a seamless anti-seepage system as a whole.

3. Outstanding corrosion resistance and stability

The molecular structure does not contain polar groups and has strong tolerance to acids (pH range 2-12), bases, salts, and organic solvents such as methanol and ethanol. Through accelerated aging tests, it has been verified that the mechanical performance degradation rate of leachate (containing COD 5000-10000mg/L) is less than 10% after long-term soaking for 10 years. In addition, the added antioxidants, light stabilizers and other additives extend their service life to over 20 years under ultraviolet irradiation (wavelength 280-400nm) environment, meeting the long-term use needs of open-pit landfills.

4. Strong adaptability to construction

The product is lightweight (weighing 3.0-6.0kg per square meter) and can be transported in rolls (with a single roll length of 50-100m), significantly reducing handling costs. During construction, efficient connection can be achieved through a hot air welding machine (welding temperature 180-220 ℃), with a welding speed of 2-5m/min and a daily construction area of over 1000 square meters. At the same time, its flexibility allows it to conform to irregular terrain (such as slopes with a gradient of ≤ 30 °), and special parts such as corners and edges can be joined together with shaped components to ensure the integrity of the anti-seepage system.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

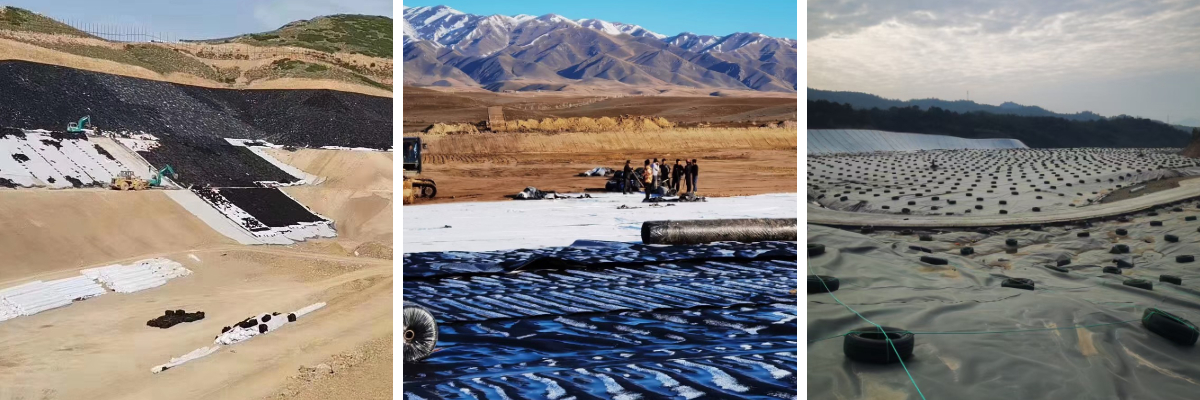

1. Landfill site for household waste

In domestic waste landfill sites, HDPE Landfill Liner geomembrane is used as the core anti-seepage layer and laid at the bottom and slopes of the landfill area (with a slope gradient of ≤ 1:1.5). The bottom adopts a composite structure of "geomembrane+geotextile+compacted clay" (total thickness of anti-seepage layer ≥ 1.5m), which can intercept daily leachate (daily processing capacity can reach 100-500m ³); When laying the slope, it should be fixed with anchor trenches (depth ≥ 0.5m) to prevent membrane slippage caused by rainwater erosion. At the same time, during the closure stage of the landfill site, it can serve as an anti-seepage component as a cover layer to prevent rainwater from seeping into the already filled area.

2. Hazardous waste landfill sites

For hazardous waste landfills such as medical waste and chemical waste residue, this product can meet the anti-seepage requirements of the "Pollution Control Standards for Hazardous Waste Landfills" (GB 18598). By adopting a dual anti-seepage system (using HDPE geomembrane with a thickness of 2.0mm or more for both the main and secondary anti-seepage layers) and setting a leakage detection layer in the middle, real-time monitoring of leaks can be achieved. When dealing with landfills containing heavy metals and corrosive waste liquids, their chemical corrosion resistance can effectively prevent membrane damage and reduce environmental pollution risks.

3. Industrial waste disposal site

HDPE geomembrane can solve the problem of high concentration salt (such as chloride ion concentration above 10000mg/L) infiltration in the leachate of industrial waste such as metallurgical waste and power plant fly ash. When laying, combined with the geogrid reinforcement layer, it can resist the lateral pressure generated by the accumulation of waste residue (maximum bearing pressure ≥ 200kPa). In addition, in waste residue resource utilization projects (such as waste residue brick raw material yards), it can be used as a site anti-seepage layer to prevent waste residue loss caused by rainwater erosion.

4. Special waste landfill site

For special waste landfill sites such as low-level radioactive waste from the nuclear industry and solidified waste from contaminated soil remediation, this product is widely used due to its strong stability and absence of harmful substance precipitation. Through customized production (such as adding anti radiation additives), the anti-seepage needs in special environments can be met. Laying HDPE geomembrane in the buffer zone around the landfill site can also form an emergency anti-seepage barrier to prevent the spread of accidentally leaked pollutants.

5. Supporting auxiliary engineering

In addition to the main body of the landfill area, this product can also be applied to supporting facilities such as leachate regulating tanks (with an anti-seepage area of over 10000 square meters), anti-seepage tanks in garbage leachate treatment stations, and rainwater collection ditches in landfills. In the regulating pool, a structure of "geomembrane+concrete cover" is adopted, which can withstand long-term immersion of high concentration leachate (COD concentration ≥ 20000mg/L); In rainwater collection systems, their UV resistance can adapt to outdoor environments and extend the service life of facilities.

HDPE Landfill Liner geomembrane, with the inherent advantages of high-density polyethylene material and precision processing technology, has built the core competitiveness of "reliable anti-seepage, stable performance, efficient construction, environmental protection and economy". Its excellent anti-seepage performance and corrosion resistance block the pollution path of garbage leachate to soil and groundwater from the source; Strong mechanical performance and construction adaptability ensure long-term stable operation in complex engineering environments; The wide range of application scenarios and full lifecycle cost advantages make it the preferred anti-seepage material for various landfill projects.