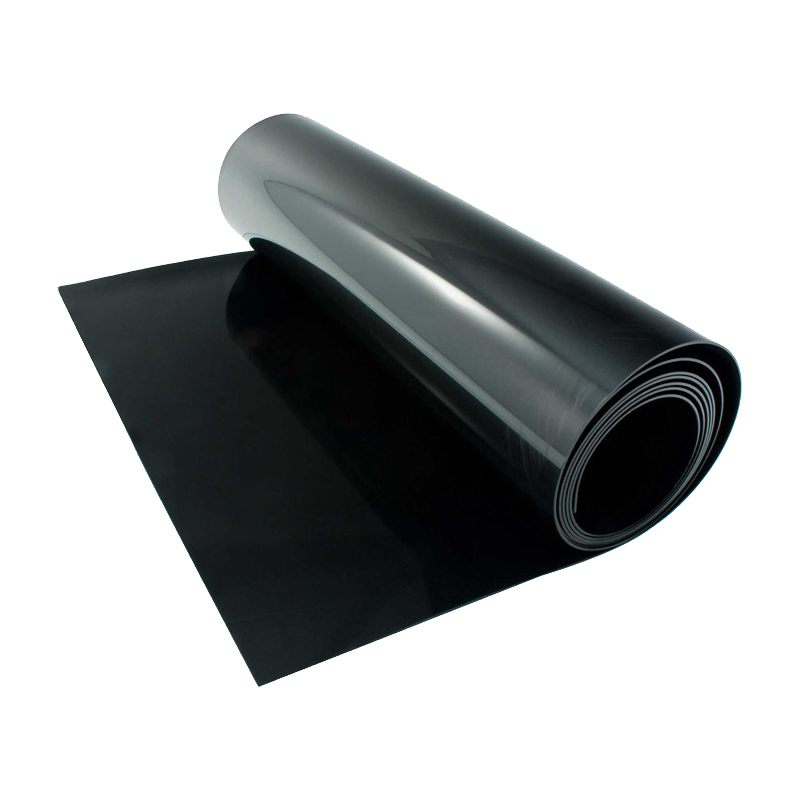

Geomembrana 2mm

1. Superior Impermeability: Its 2mm thickness ensures excellent impermeability, effectively blocking liquid and gas penetration, suitable for projects with stringent impermeability requirements.

2. Strong Puncture Resistance: The tough material can withstand punctures from sharp objects encountered during construction and use, ensuring the integrity of the seepage prevention system.

3. Excellent Weather Resistance: Outstanding UV resistance and anti-aging properties allow it to maintain stable performance even under prolonged exposure to sunlight and rain, extending its service life.

4. Convenient and Efficient Construction: Its good flexibility makes it easy to cut, weld, and lay, adapting to complex terrain, improving construction efficiency, and reducing installation costs.

Product Introduction

Basic attributes

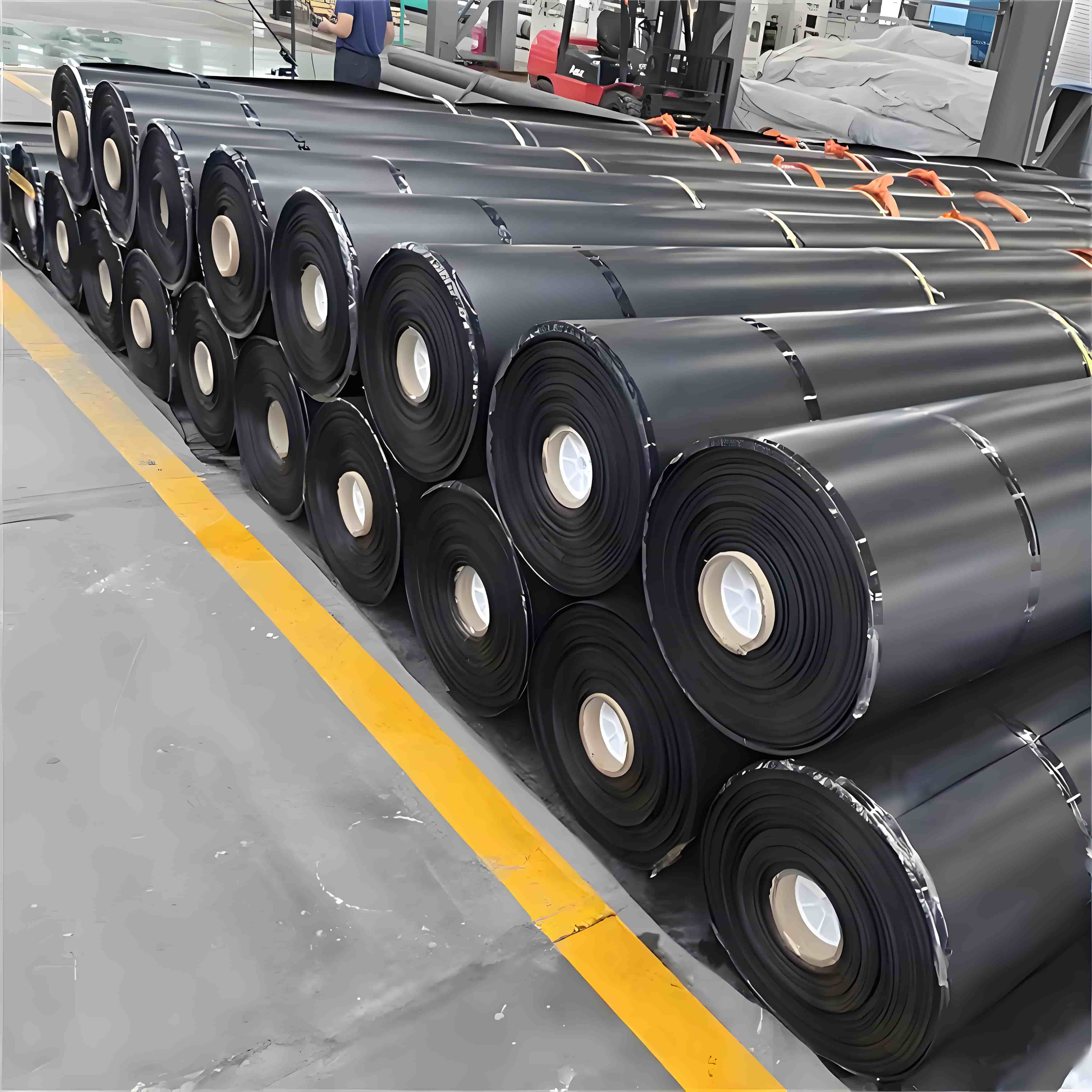

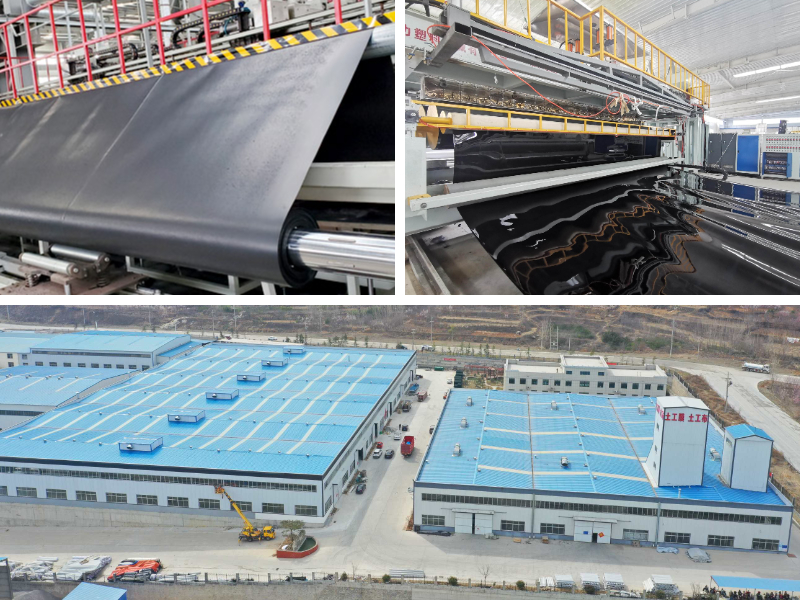

The basic properties of Geomembrana 2mm is reflected in their material and form. It is mainly made from high molecular weight polymers such as high-density polyethylene and polyvinyl chloride, processed through special techniques. The appearance is mostly in the form of a thin film, with uniform thickness, lightweight texture, and certain flexibility and tensile strength. It can be cut and spliced according to the actual needs of the project, and can adapt well to the size, shape, and terrain changes of different projects. Whether it is a flat, curved or irregular slope, it can achieve a tight fit.

Core functions

The core function of geomembrane is anti-seepage and isolation. In hydraulic engineering, such as reservoirs, dams, channels, etc., it can effectively prevent water leakage, ensure the rational use of water resources and the safety of the project; In environmental engineering, facilities such as landfills and sewage treatment tanks can prevent leachate from seeping into soil and groundwater, thus avoiding environmental pollution; At the same time, in fields such as transportation and mining, it can also serve to isolate different media, prevent soil mixing and loss, maintain the stability of engineering structures, and provide basic support for the normal operation of various projects.

Main features

The main characteristics of geomembranes are very distinct. Firstly, it has strong weather resistance and can resist the influence of natural environmental factors such as ultraviolet radiation and changes in high and low temperatures. Its performance is not easily degraded when exposed to the outside for a long time; Secondly, it has outstanding corrosion resistance and can withstand the erosion of chemical substances such as acid, alkali, and salt, extending its service life; Thirdly, the construction is convenient, the laying process is simple, and there is no need for complex equipment. The joints are made using hot melt welding and other processes, which are firm and reliable, and can effectively shorten the construction period; Fourthly, it is economical and practical. Not only is the procurement cost relatively reasonable, but the maintenance cost in the later stage is also low, and the comprehensive cost-effectiveness is high. At the same time, the material itself is non-toxic and harmless, which meets environmental protection requirements.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

Water conservancy engineering field

In the construction of reservoirs and dams, geomembranes are laid on the surface or inside of the dam body to form an anti-seepage layer, prevent water leakage from the reservoir, ensure the stability and safety of the dam, and reduce the risks of dam deformation and collapse caused by leakage. In channel engineering, it can be laid on the inner wall of the channel to prevent the infiltration and loss of water resources during transportation, improve the utilization efficiency of water resources, especially suitable for irrigation channels in arid areas.

Environmental engineering field

Landfills are an important application scenario for geomembranes. Laying them at the bottom and surrounding areas of landfills can effectively block the infiltration of leachate into the soil and groundwater, avoiding pollution to the surrounding environment. At the same time, it prevents groundwater from entering the landfill and reduces the amount of leachate produced. In sewage treatment tanks, geomembranes can serve as anti-seepage materials to prevent sewage leakage, ensure the normal operation of sewage treatment processes, and protect the surrounding soil and water environment.

Transportation engineering field

In the construction of roadbeds for highways and railways, geomembranes can be laid between the roadbed and the base layer to provide isolation, prevent mixing between different soil layers, avoid soil erosion and settlement damage, and enhance the stability of the roadbed. In tunnel engineering, it can serve as a waterproof layer to prevent groundwater from seeping into the interior of the tunnel, ensuring the safety of the tunnel structure and driving safety.

Mining engineering field

In the tailings pond of a mine, geomembranes are used for anti-seepage treatment in the pond area, preventing harmful substances in the tailings slurry from penetrating into the surrounding soil and water, and reducing the risk of environmental pollution. At the same time, geomembranes are also used for anti-seepage in sedimentation tanks, heap leaching tanks and other facilities during the mining process to ensure that the production process meets environmental standards.

Agriculture and Horticulture

Laying geomembranes in agricultural irrigation reservoirs and irrigation channels can reduce water leakage and improve water resource utilization efficiency. In horticultural planting, some greenhouse foundations or planting pools use geomembranes to prevent seepage, isolate soil, and control moisture and nutrients, creating a suitable environment for plant growth.

From water conservancy and environmental protection to transportation, mining, and even agriculture and horticulture, geomembranes play an indispensable role due to their excellent anti-seepage and isolation properties. It not only ensures the safe and stable operation of various projects, improves resource utilization efficiency, but also makes significant contributions to environmental protection, becoming a widely used and crucial material in modern engineering construction.