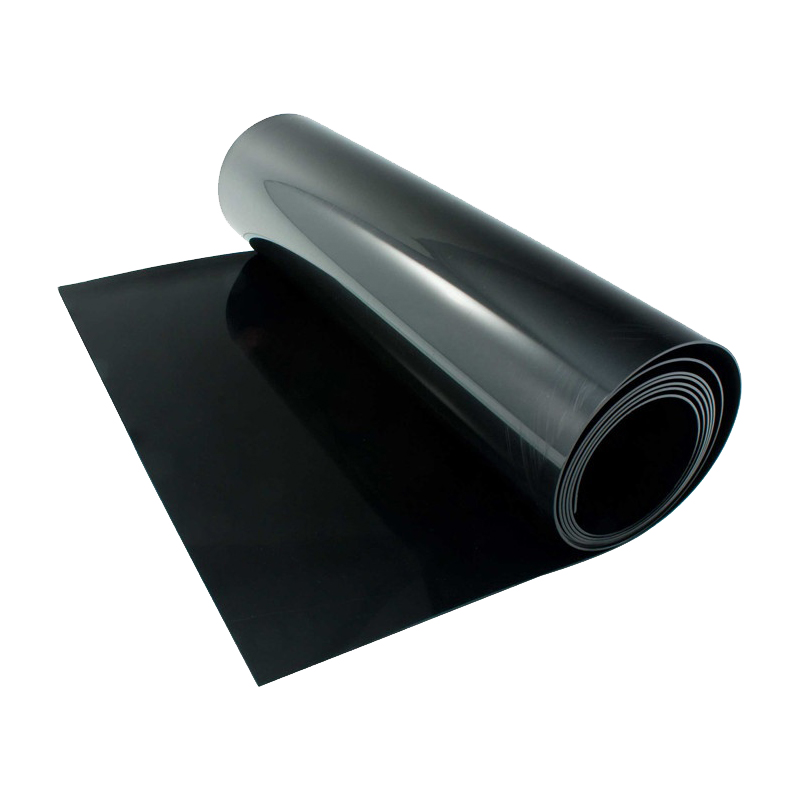

Geomembrane in HDPE

1. Strong anti-seepage: The permeability coefficient is ≤ 1 × 10 ⁻¹³ cm/s, which can effectively prevent the infiltration of liquids and gases. It is suitable for various anti-seepage scenarios such as landfill and water conservancy projects.

2. Chemical corrosion resistance: It can resist more than 80 types of strong acid and alkali erosion, maintain stability in complex chemical environments such as chemical plants and sewage treatment, and ensure engineering safety.

3. Anti aging and durable: with the addition of special additives, the outdoor service life is more than 50 years, which can withstand natural influences such as sunshine, temperature difference, and reduce replacement costs.

4. Strong and resilient adaptation: The tensile strength at break is ≥ 16N/mm, and the elongation at break is ≥ 700%. It is both tensile and flexible, and can adapt to foundation settlement, making it easy to construct.

Products Introduction:

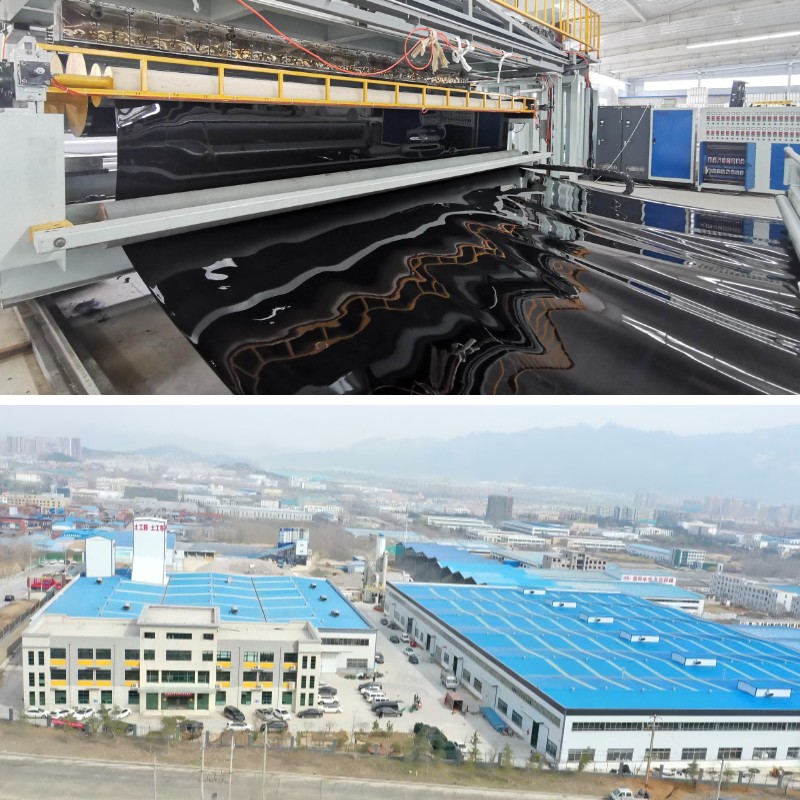

Geomembrane in HDPE, also known as high-density polyethylene film or HDPE anti-seepage film, is a plastic roll made of highly crystalline and non-polar thermoplastic resin HDPE. The original appearance of HDPE is milky white, with a certain degree of semi transparency at the thin section. Its production takes high-quality polyethylene resin as the main material (including about 97.5% high-density polyethylene), with about 2.5% carbon black, anti-aging agent, antioxidant, ultraviolet absorber, stabilizer and other auxiliary materials. The product has a thickness range of 0.2mm -3mm, excellent resistance to environmental stress cracking, low temperature resistance, aging resistance, corrosion resistance, wide temperature range (-60 ℃ to+60 ℃), and a service life of up to 50 years.

Product Features:

1. Excellent anti-seepage performance: The permeability coefficient of HDPE geomembrane is extremely low, usually between 10 ⁻¹⁷ and 10 ⁻² ¹ cm/s, which can effectively block the penetration of moisture, liquids, and gases. The waterproof and anti-seepage effect far exceeds that of ordinary waterproof materials, ensuring the waterproof sealing of the project.

2. High strength and tear resistance: It has high tensile strength and tear strength, can withstand soil pressure and other types of loads, reduce the risk of damage during construction and use, and is suitable for projects that require high material strength.

3. Chemical corrosion resistance: It exhibits excellent resistance to various chemical substances such as acids, alkalis, and salts, and can be used stably for a long time in complex chemical environments such as pollution control and mining.

4. UV resistance and aging resistance: by adding UV stabilizer and other means, it can resist UV erosion for a long time in outdoor environment, maintain stability, delay aging process and extend service life.

5. Good temperature adaptability: It can be used normally within the temperature range of -70 ℃ to 70 ℃, and can adapt to environmental temperature changes and maintain stable performance in both cold and hot regions.

6. Anti puncture and anti root performance: It has excellent anti puncture ability and can resist most plant root system punctures, suitable for scenarios such as rooftop planting and landfill sites that require high material anti puncture and anti root penetration requirements.

7. Convenient construction: The material has good flexibility and can be cut into different specifications and sizes, which can adapt to various laying forms and complex terrains. It is connected by hot melt welding and other methods, with high welding strength and fast construction speed, which can effectively shorten the construction period.

8. Environmentally friendly and non-toxic: using environmentally friendly raw materials, the production process does not add harmful chemicals, and there will be no harmful substances polluting the environment during use. It can be used in fields with strict environmental requirements such as environmental protection, agriculture, and aquaculture.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

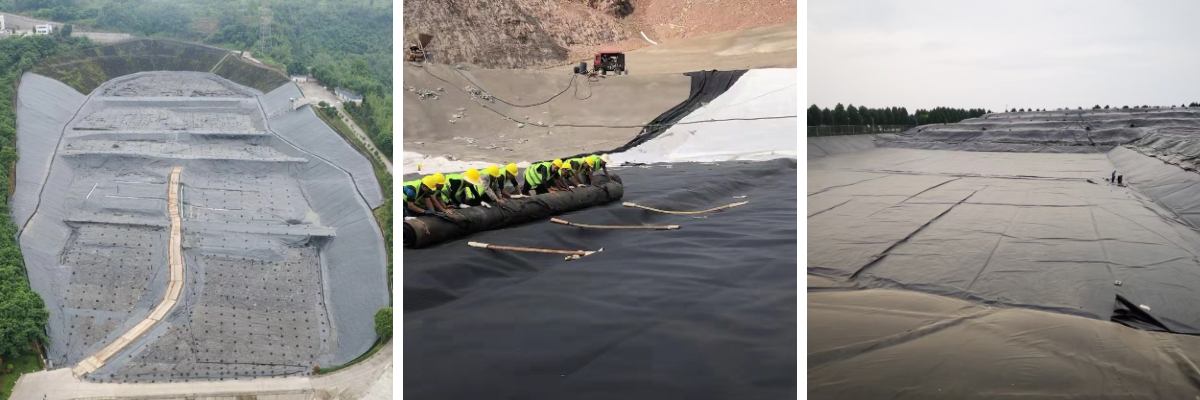

Product Applications:

1. Environmental engineering

Landfill site: As an anti-seepage layer at the bottom and slope of the landfill site, it effectively prevents leachate from seeping into the ground, polluting soil and groundwater. At the same time, it cooperates with the drainage layer to timely export leachate and biogas.

Sewage treatment plant: used for anti-seepage of sewage treatment tanks, regulating tanks and other facilities, preventing sewage leakage, ensuring the normal operation of sewage treatment systems, and avoiding pollution to the surrounding environment.

Hazardous waste disposal site: effectively isolate hazardous waste, prevent the spread of hazardous substances, ensure environmental safety, and meet strict environmental protection requirements.

2. Water conservancy engineering

Reservoirs and artificial lakes: laid at the bottom and slopes of reservoirs and artificial lakes as anti-seepage layers, reducing water leakage, improving water storage efficiency, and maintaining the water storage function of water conservancy facilities.

Channel: Used in irrigation channels, water conveyance channels, etc., to prevent water leakage in channels, improve water resource utilization efficiency, and ensure the smooth progress of water conservancy irrigation and water conveyance projects.

3. Agricultural field

Biogas digester: The biogas digester is sealed to prevent biogas leakage, ensure fermentation efficiency, improve energy utilization efficiency, and promote the development of clean energy in agriculture.

Breeding Pool: The lining of the breeding pool prevents water leakage, maintains a stable breeding environment, reduces water waste, and avoids pollution of surrounding soil and water bodies by breeding wastewater.

4. Other fields

Mining: anti-seepage treatment of washing ponds, heap leaching ponds, tailings ponds, etc., to prevent the leakage of wastewater containing harmful substances such as heavy metals and avoid pollution to the surrounding environment.

Transportation facilities: road foundation reinforcement, culvert anti-seepage, etc., improve the stability and durability of transportation infrastructure, and reduce structural damage caused by water infiltration.

Municipal engineering: anti-seepage of underground engineering in subways and buildings to prevent groundwater leakage from affecting the safety of engineering structures; Planting waterproof and moisture-proof roofs and rooftop gardens provides a good environment for plant growth.

HDPE geomembrane has become an indispensable high-performance material in the field of civil engineering and environmental protection due to its excellent impermeability, high strength, chemical corrosion resistance, aging resistance, convenient construction and other characteristics. Effective pollution prevention and control in environmental engineering, efficient water conservation and preservation in water conservancy engineering, agriculture and other industries also play an important role. Its environmentally friendly and non-toxic characteristics are in line with the current concept of green development, and it is widely used to provide solid guarantees for the stable operation and environmental protection of various projects. With the development of technology, HDPE geomembrane will demonstrate its advantages in more fields and contribute to engineering construction and ecological protection.