HDPE Pool Liner

1. High durability:It has excellent chlorine resistance and UV resistance, is not easy to corrode or age, has high physical strength, and has a long service life.

2. Safe and environmentally friendly:It contains no toxic substances, does not release harmful components, and has a smooth and non-slip surface, reducing the risk of scratches and slips.

3. Easy maintenance:Dirt is difficult to adhere to and easy to clean, it is not easy to breed bacteria and algae, the joints have good sealing performance, there is little water leakage, and the maintenance cost is low.

4. Flexible adaptation:It can be customized and cut to fit irregularly shaped swimming pools, is suitable for both new and old swimming pools, and has low requirements on the original structure for installation.

Product Introduction

1. Basic Properties: Material Essence and Inherent Characteristics

• Material Category: HDPE Pool Liner is a thermoplastic resin made from high-density polyethylene particles through a special process, and is an environmentally friendly synthetic material.

• Core Characteristics: It has a dense molecular structure and high crystallinity, and inherently possesses physical and chemical properties such as resistance to chemical corrosion, ultraviolet aging, stretching, and tearing.

• Safety Standards: It does not contain toxic substances such as phthalates and heavy metals, meets international safety standards for water-related products, and can be in direct contact with swimming pool water.

2. Core Functions: Meeting the Core Needs of Swimming Pools

• Waterproof Sealing: As the "waterproof layer" of the swimming pool, it can closely fit the pool body, block the penetration of pool water, prevent the pool structure from being damaged due to water seepage, and reduce the risk of water leakage.

• Pool Body Protection: It isolates the pool water and disinfectants from the pool body (such as concrete and masonry), prevents the pool body from being corroded by chemicals or worn by water flow, and prolongs the overall service life of the swimming pool.

• Water Quality Assurance: The material itself does not release harmful pollutants, is not easy to absorb impurities, reduces secondary pollution of water quality, and helps maintain the cleanliness of the swimming pool water.

3. Main Features: Advantages Distinguishing from Other Liners

• Outstanding Durability: Compared with ordinary PVC liners, it has stronger resistance to aging and chlorine corrosion. Under normal use, its service life can reach 10-15 years, which is much longer than that of traditional liners.

• Low Maintenance Cost: The surface is smooth and dense, making it difficult for scale and algae to adhere. Daily maintenance only requires simple flushing; there are few seams and good sealing performance, which significantly reduces the frequency and cost of subsequent repairs.

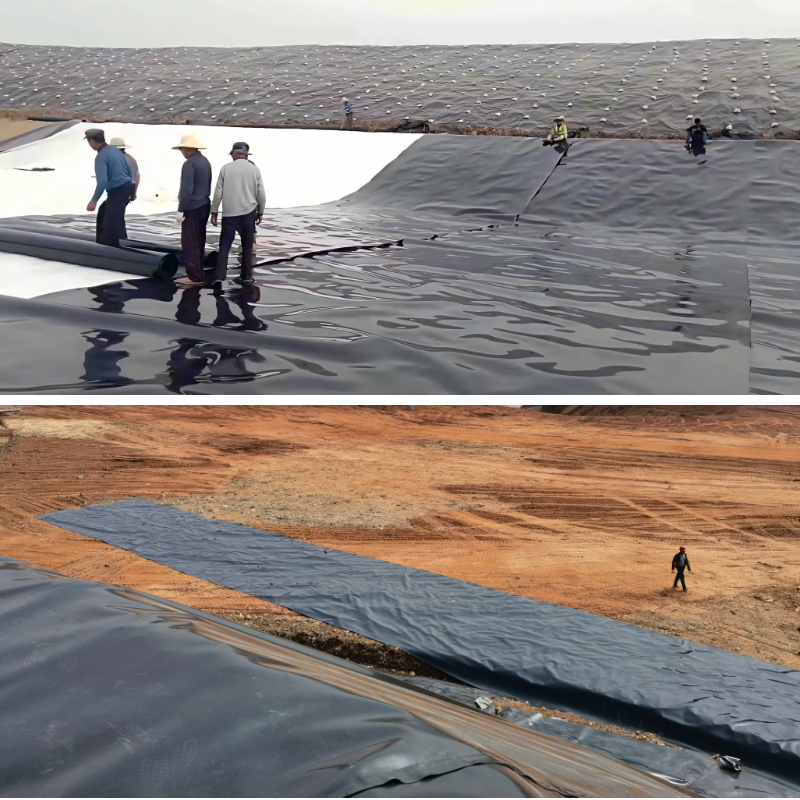

• Flexible Adaptability: It can be custom-cut according to the special-shaped structure of the pool (such as circular and irregular shapes). It can be used for newly built pools and can also be directly covered on old pool liners for renovation, with convenient installation.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

1. Domestic swimming pool scenarios

• Private courtyard swimming pools / villa swimming pools: Can be custom-cut according to the irregular structures of the courtyard space (such as circular, arc-shaped, irregular shapes) to perfectly fit the pool body. There is no need for complex modifications to the original ground, and the installation cycle is short, meeting the family's dual needs for the beauty and practicality of the swimming pool.

• Family paddling pools / children's swimming pools: The material contains no toxic substances, and the surface is smooth and non-slip, which can prevent children from being scratched or slipping when in contact. It also has strong anti-pollution ability, reducing the pressure of frequent water changes and cleaning for children's swimming pools.

2. Commercial swimming pool scenarios

• Public swimming pools / fitness club swimming pools: With high daily usage frequency and a large number of people in contact, HDPE liners have strong chlorine corrosion resistance and wear resistance, can withstand long-term high-frequency water flow impact and personnel friction, and have a service life of 10-15 years, reducing the maintenance and renovation costs of commercial swimming pools.

• Hotel / resort swimming pools: Balancing beauty and durability, they can be customized in colors (such as blue, transparent) to match the pool landscape design. At the same time, they are resistant to ultraviolet aging, and are not easy to fade or crack when exposed to the outdoors for a long time, ensuring the long-term beauty of hotel swimming pools.

3. Special water body scenarios

• Hot spring pools / SPA swimming pools: Can withstand the medium and high temperatures of hot spring water (usually 40-60℃) and possible added minerals, essential oils and other ingredients, are not corroded by chemical substances, and have good sealing performance, avoiding heat loss caused by hot spring water leakage.

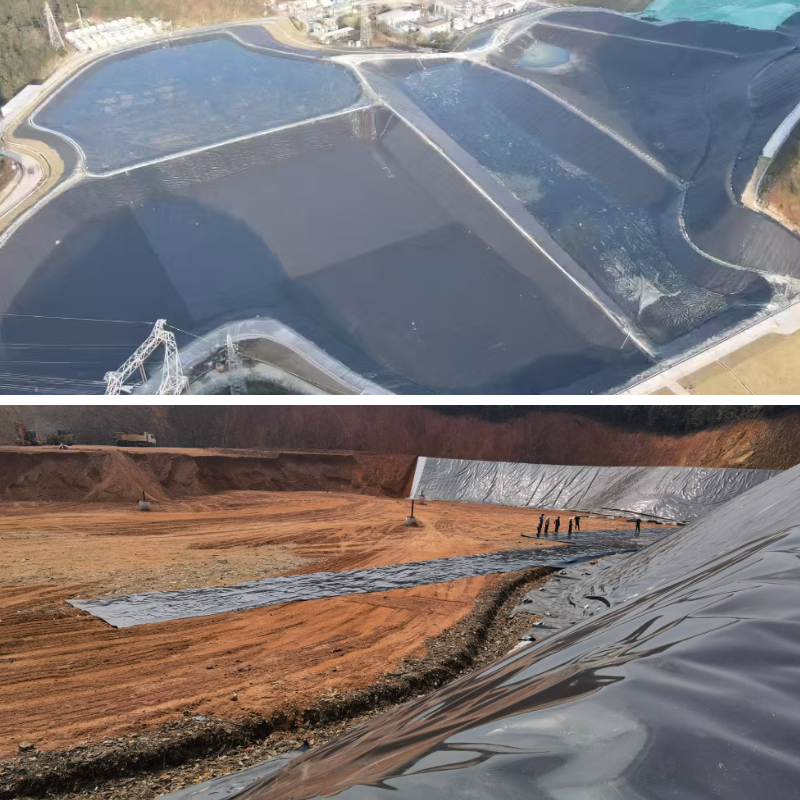

• Aquaculture pools / landscape water pools: In addition to swimming pools, they can also be used for water containers such as koi ponds and ornamental fish ponds. Their impermeability can prevent water leakage. At the same time, the material does not release harmful substances, will not affect the survival of aquatic organisms, and the surface is smooth and easy to clean, reducing algae growth.

4. Old swimming pool renovation scenarios

• Renovation of old swimming pools: Aiming at the problems of leakage in traditional concrete swimming pools and aging and cracking of original liners (such as PVC), HDPE liners can be directly laid on the surface of the original pool body without removing the old structure, greatly shortening the renovation period (usually completed in 1-2 weeks), and can solve the problems of leakage and corrosion at one time, extending the service life of old swimming pools.

• Temporary swimming pool construction: In exhibition, event temporary swimming pools or mobile swimming pools, HDPE liners are light in weight, easy to carry, can be quickly laid and sealed. After the event, they can be disassembled and recycled, adapting to the flexible needs of temporary water scenarios.

5. Extreme environment applications

• Swimming pools in cold regions: In the low-temperature environment of northern winters, HDPE liners have strong low-temperature impact resistance, will not be brittle and crack due to freeze-thaw cycles (water freezing and expanding), can ensure that the swimming pool does not leak in winter, and reduce the damage to the pool body caused by low temperatures.

• Underground / semi-underground swimming pools: In view of the soil water pressure borne by underground swimming pools, HDPE liners have stronger tensile resistance and impermeability, can effectively block groundwater backflow, and at the same time isolate harmful substances in the soil to protect the water quality of the swimming pool.

The application of HDPE pool liners covers all scenarios from household to commercial use, from regular swimming pools to special water bodies, and from new construction to renovation. The core lies in their three major advantages: durability, adaptability, and safety, which can accurately meet the core needs of different scenarios. They not only solve the problems of customization and safety in household scenarios but also meet the needs of high-frequency use and low maintenance in commercial scenarios. Additionally, they can address the pain points in special scenarios such as renovation and extreme environments. Ultimately, they achieve the application value of "reducing costs, extending service life, and flexible adaptation" and become the preferred solution for sealing and protecting various water containers.