Non Woven Paving Fabric

1. Isolation and pollution prevention: Separate the surface layer from the base layer to prevent fine soil pollution and prevent road cracking and sanding.

2. Water filtration and base protection: Quickly drain accumulated water, prevent base softening, and reduce road settlement and depression.

3. Buffer crack resistance: Disperse load stress, reduce fatigue cracking and reflection cracking.

4. Easy to lay economy: temperature resistant and flexible, can be laid manually, and has a lower cost than traditional materials.

Products Introduction:

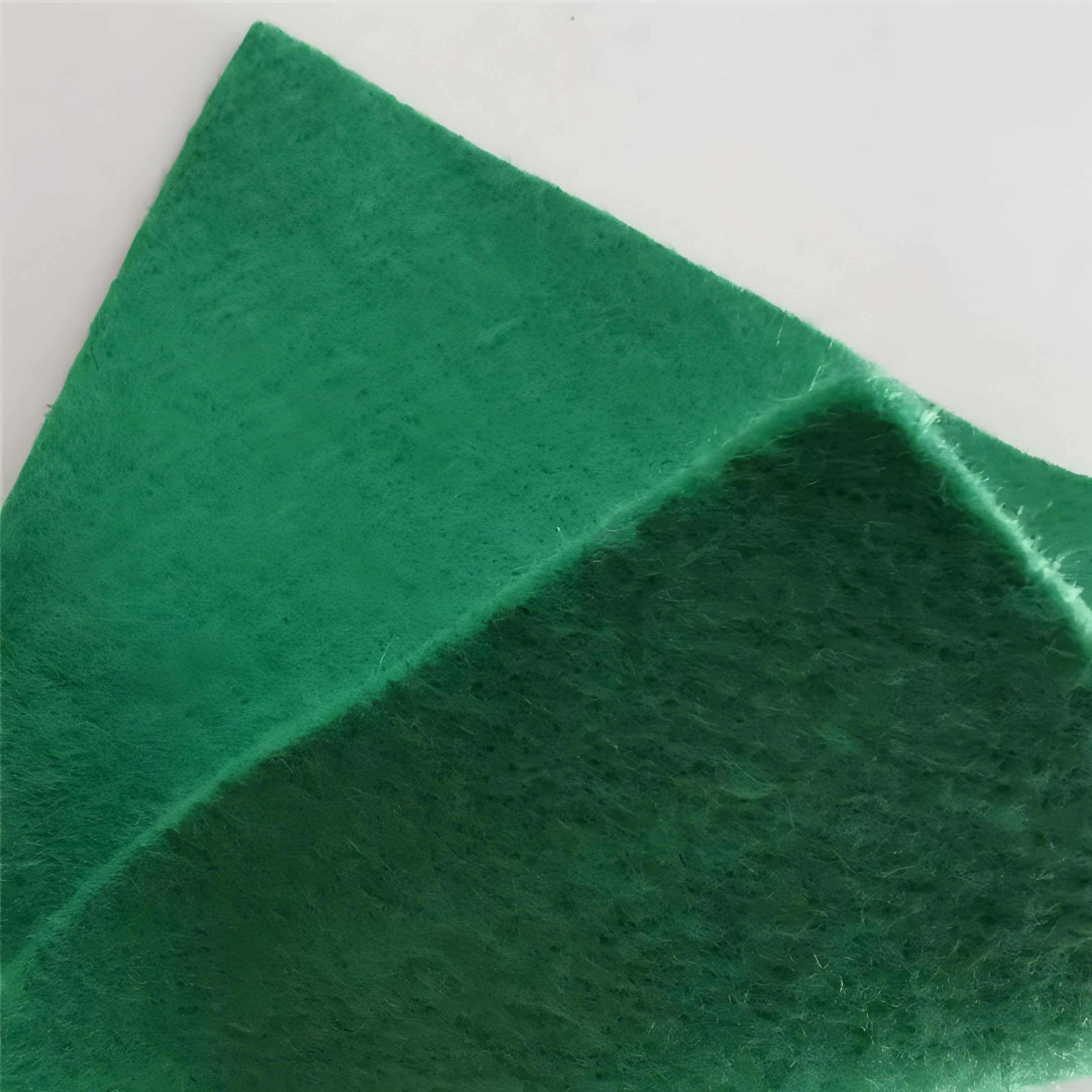

Non Woven Paving Fabric is a non-woven geosynthetic material designed specifically for the protection between the base and surface layers of road surfaces. It is made from short fibers of polypropylene (PP) or polyester (PET), which are randomly interwoven and consolidated through needle punching or thermal bonding processes. Its core function is to be laid between the base layer (such as sand layer and soil base) and the surface layer of asphalt pavement and cement pavement, playing the role of "isolation and protection, filtering and drainage, buffering and reinforcement", solving the early damage problems caused by impurities pollution, water erosion, and stress concentration in the base layer of the pavement, and is a key supporting material for improving the stability and service life of the pavement structure.

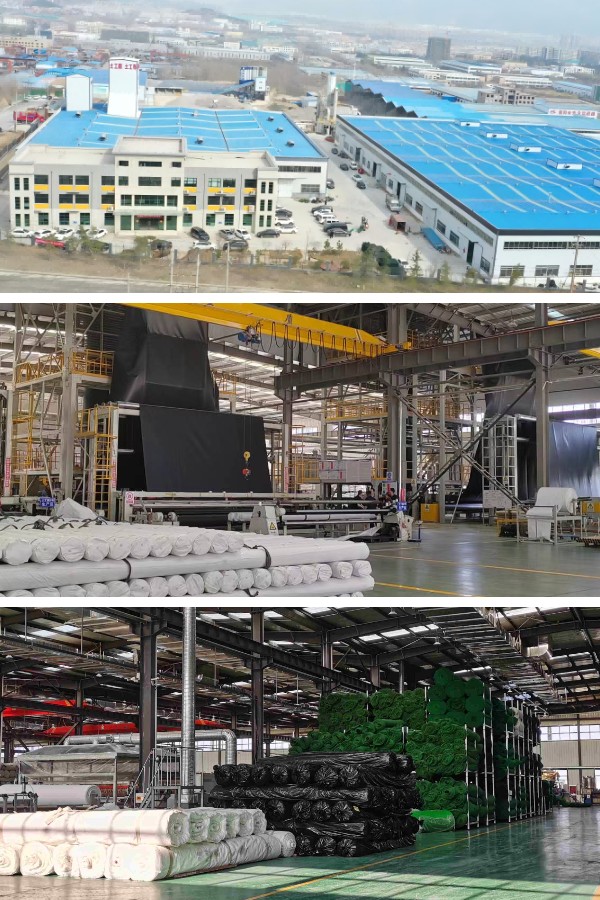

Compared with woven paving fabrics, non-woven paving fabrics are widely used in small and medium-sized road construction projects due to their superior permeability, flexibility, and adhesion. They are particularly suitable for rural roads, municipal streets, parking lots, and other scenarios, providing low-cost and efficient protection solutions for road surfaces.

Product Features:

1. Efficient isolation and prevention of material mixing: random interweaving of fibers forms a fine and uniform three-dimensional pore structure (pore size 0.05-0.2mm), which can effectively separate the pavement surface layer (asphalt or cement) from the base sand, gravel, and soil, prevent fine soil particles and dust in the base from infiltrating and polluting the surface layer with vehicle loads or rainwater, and avoid dilution of asphalt binder and sanding of cement surface layer; At the same time, it prevents the infiltration of high-temperature asphalt or cement slurry into the gaps of the base layer, ensuring the structural independence of the surface layer and the base layer, and reducing the cracking and arching of the road surface caused by material mixing.

2. Filter and drain, protect the stability of the base layer: with excellent permeability (permeability coefficient ≥ 1 × 10 ⁻ cm/s), it can quickly guide the accumulated water in the base layer (such as rainwater infiltration and capillary rise of groundwater), prevent water from staying between the base layer and the surface layer, avoid softening of the base soil due to accumulated water, and reduce the bearing capacity, thereby reducing road settlement and depression; Simultaneously intercepting fine particles in the base layer to prevent them from blocking drainage channels with water flow, maintaining long-term smoothness of the drainage system, especially suitable for road engineering in rainy areas.

3. Buffer reinforcement, dispersing load stress: It has a certain tensile strength (5-20kN/m) and elastic modulus. After laying, it forms a "composite buffer layer" with the base and surface layers, which can disperse the local stress generated by vehicle loads and reduce the risk of fatigue cracking of the surface layer caused by long-term repeated loads; At the same time, when there is slight settlement at the grassroots level, it absorbs deformation energy through its own flexibility, reduces reflection cracks (such as the transmission of grassroots cracks to the new surface layer during the renovation of old roads), and extends the service life of the road surface by 3-5 years.

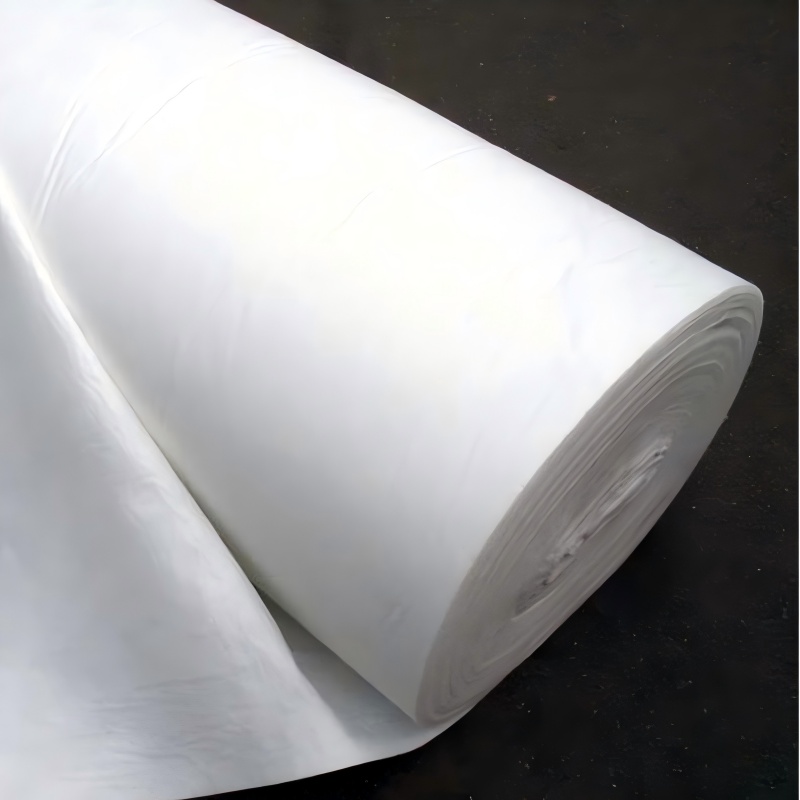

4. Temperature resistant adaptation, easy construction and cost reduction: After high-temperature treatment (temperature resistance ≥ 160 ℃), it can withstand the high temperature baking during asphalt paving without deformation or degradation; The texture is flexible (thickness 1-3mm), lightweight (100-300g/m ²), and can tightly adhere to the undulating surface of the base layer. No professional equipment is required for laying, and manual overlap (overlap width ≥ 10cm) can be completed. It is compatible with the operation process of asphalt pavers and cement pavers, and the construction efficiency is 30% higher than traditional fiberglass grids, reducing material costs by 10% -15%.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Rural roads and county and township roads: When "hardening and transforming" rural dirt roads (laying asphalt or cement surface layers), they are laid between the soil base and surface layer, focusing on solving the problems of fine soil pollution and rainwater erosion at the grassroots level, reducing the marks and cracks caused by agricultural machinery rolling on the road surface, extending the maintenance cycle of rural roads, and adapting to low-grade highways with short mileage and relatively small loads.

2. Municipal streets, alleys, and community roads: used for laying urban secondary roads, branch roads, and internal roads in residential areas. Through filtering and drainage functions, it can cope with frequent rainwater infiltration during the rainy season and prevent road surface depressions caused by softening of the base layer; At the same time, isolate the fine soil at the grassroots level, reduce the common phenomena of "road sanding" and "local damage" on municipal roads, improve road durability, and reduce later maintenance costs.

3. Parking lot and square ground: It is laid under the asphalt or cement ground of large parking lots and commercial squares to adapt to the local loads caused by frequent vehicle starts and stops, and to reduce cracks caused by stress concentration on the ground through buffering and reinforcement; At the same time, the surface water should be drained to avoid damage to the base of the parking lot caused by water accumulation, and the ground should be kept flat and tidy.

4. Renovation and overlay engineering of old roads: In the overlay and renovation engineering of old asphalt or cement roads, it is laid between the old road surface and the new surface layer to isolate loose particles, cracks, and the new surface layer of the old road surface, and prevent the generation of reflective cracks; Simultaneously buffering the deformation differences between the old and new structural layers, enhancing the overall integrity of the structure, and reducing the frequency of maintenance in the later stages of renovation projects.

Non Woven Paving Fabric focuses on the core pain points of small and medium-sized pavement engineering, with the core advantages of "isolation and anti mixing, filtering and drainage, buffering and crack resistance, temperature resistance and easy construction", providing full cycle basic protection for pavement structures. Whether it is the hardening and renovation of rural roads or the daily maintenance of municipal streets and alleys, they can significantly extend the service life of the road surface and reduce maintenance investment through scientific performance design while controlling costs.

The product combines functionality and economy, with convenient construction and adaptability to various road paving processes, especially suitable for cost sensitive and limited construction conditions scenarios. It is an ideal supporting material for achieving the goal of "low cost and long service life" in modern lightweight road engineering, providing reliable guarantee for the collaborative work of base and surface layers, and promoting the development of road construction towards a more efficient and durable direction.