Gravel Geotextile

1. Reinforcement and strengthening: Geotextiles have high tensile strength, which can effectively disperse loads, improve the overall stability and bearing capacity of the soil, and prevent deformation and cracking.

2. Isolation and protection: It can isolate soil layers or materials of different properties, prevent them from mixing with each other, and maintain the integrity and function of each layer structure.

3. Drainage filtration: allows water to pass smoothly while effectively preventing the loss of soil particles, playing a filtering role of "permeable but impermeable" to prevent the foundation from being hollowed out.

4. Efficient construction, economical and durable: light material and roll supply make laying simple, which can greatly save material, labor and time costs, and is corrosion resistant, anti-aging, and has a long service life.

Product Introduction:

Gravel Geotextile is a permeable polymer (plastic) textile material specifically used in civil engineering. It is usually made of synthetic fibers such as polyester (PET) and polypropylene (PP) through processes such as needle punching, weaving, or spunbonding, forming a cloth like roll material, hence commonly known as "geotextile" in China.

Its core function is to interact with soil, rock or other geotechnical engineering materials, playing one or more functions such as reinforcement, protection, drainage, filtration, isolation, etc.

Main Features

1. High strength and durability: It has high tensile, tear, burst, and puncture strength.

2. Good permeability and filtration: It has a porous structure that allows water to pass smoothly in a direction perpendicular to its plane.

3. Isolation function: placed between two different types of soil or materials. Prevent them from mixing with each other and maintain their respective structural integrity and performance. For example, to prevent soft foundation soil from invading the gravel base and maintain the thickness and bearing capacity of the base.

4. Reinforcement and strengthening effect: It has high tensile strength and can disperse loads. When buried in soil, the lateral displacement of the soil can be limited and the stress of the soil can be shared through friction with the soil, greatly improving the strength and stability of the soil, similar to "steel bars in reinforced concrete".

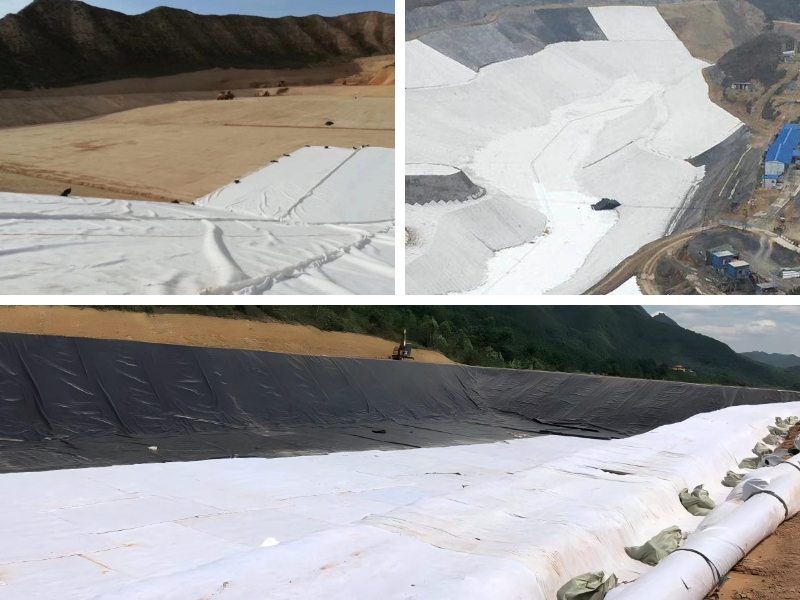

5. Protective function: It has good extensibility and buffering ability. It can serve as a buffer layer to reduce or prevent the geomembrane (anti-seepage material) from being punctured by sharp stones, protecting the waterproof layer.

6. Easy construction and high economic benefits: light weight, roll supply, easy handling and laying. Significantly reduce the amount of natural materials such as stone and sand, save excavation and transportation costs, shorten the construction period, and lower the overall project cost.

Main categories

According to different manufacturing processes and structures, geotextiles are mainly divided into the following categories:

Manufacturing process: Short fibers or long fibers are randomly arranged through needle punching or thermal bonding.

Features: It looks like felt, isotropic (with little difference in performance in all directions), and has good filtering, drainage, and isolation functions. This is the most widely used type of geotextile.

Common weight: 100g/m ²~800g/m ² or higher.

2. Woven geotextile:

Manufacturing process: Woven from fiber filaments or flat strips in a certain direction, similar to the material of woven bags.

Characteristics: Anisotropy (significant difference in strength between warp and weft directions), high tensile strength and modulus, mainly used for reinforcement and strengthening applications, but the filtration and drainage performance is not as good as non-woven fabrics.

Manufacturing process: Made using a knitted coil structure.

Characteristics: Relatively less applied, with high elasticity, suitable for some special reinforcement applications.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

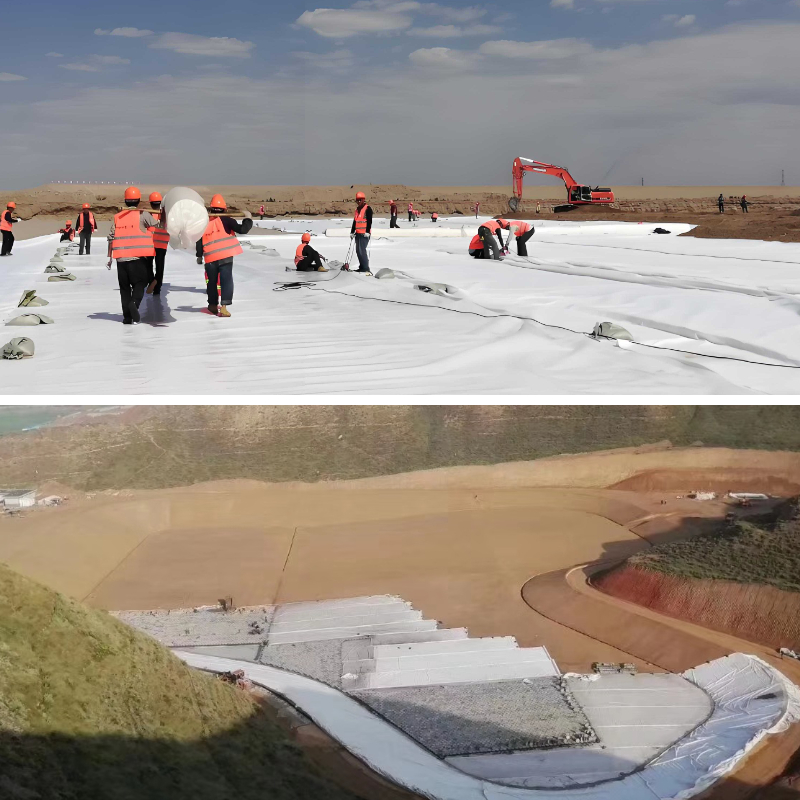

1. Water conservancy engineering

Anti seepage and slope protection of dams and channels: Use geotextile to isolate the fill soil and foundation of the dam body to prevent pipe surge; Laying on the surface of the dam to protect the soil from being washed away by water flow.

River regulation: used for reinforcing riverbanks, laying riverbeds, and reducing erosion of embankments by water flow.

2. Transportation Engineering

Highway and railway subgrade: isolate the subgrade soil from the cushion material (such as gravel) to prevent subgrade settlement; Reinforced soft soil foundation to improve bearing capacity.

Road maintenance: Lay it between the old and new road surfaces to reduce reflection cracks and extend the service life of the road surface.

3. Municipal engineering

Underground drainage system: used as a filtration layer for rainwater pipelines and sewage treatment plants to prevent sediment from blocking the pipes.

Landfill site: serves as an isolation and filtration layer to prevent soil and groundwater contamination by leachate.

4. Architecture and Mining

Building foundation: Treat soft soil foundation and reduce settlement through reinforcement.

Mining engineering: used for anti-seepage, filtration, and control of wastewater and tailings leakage in tailings dams.

5. Agriculture and Environmental Protection

Agricultural water conservancy: used for anti-seepage and drainage of irrigation channels, improving water resource utilization efficiency.

Ecological restoration: Ecological slope protection of rivers and wetlands, combined with vegetation planting, balancing protection and ecological functions.

Geotextile has become an indispensable material in modern civil engineering due to its multifunctionality, durability, and economy. It plays an important role in improving engineering quality, reducing costs, and protecting the ecological environment. With the development of technology, its application fields are constantly expanding.