HDPE Liner Sheet

• It has outstanding mechanical properties, high tensile strength, good toughness, puncture resistance, deformation resistance, and can adapt to foundation settlement.

• It has strong environmental adaptability, can resist high and low temperatures, and is resistant to ultraviolet aging.

• It has excellent anti-seepage performance, a very low coefficient of permeability, and a remarkable effect in blocking liquid leakage.

• The material is non-toxic and harmless, does not pollute water and soil, can be recycled after being discarded, and meets environmental protection requirements.

• It has a long lifespan, low construction cost, outstanding cost-effectiveness in large-scale projects, and can be recycled and reused.

Product Introduction:

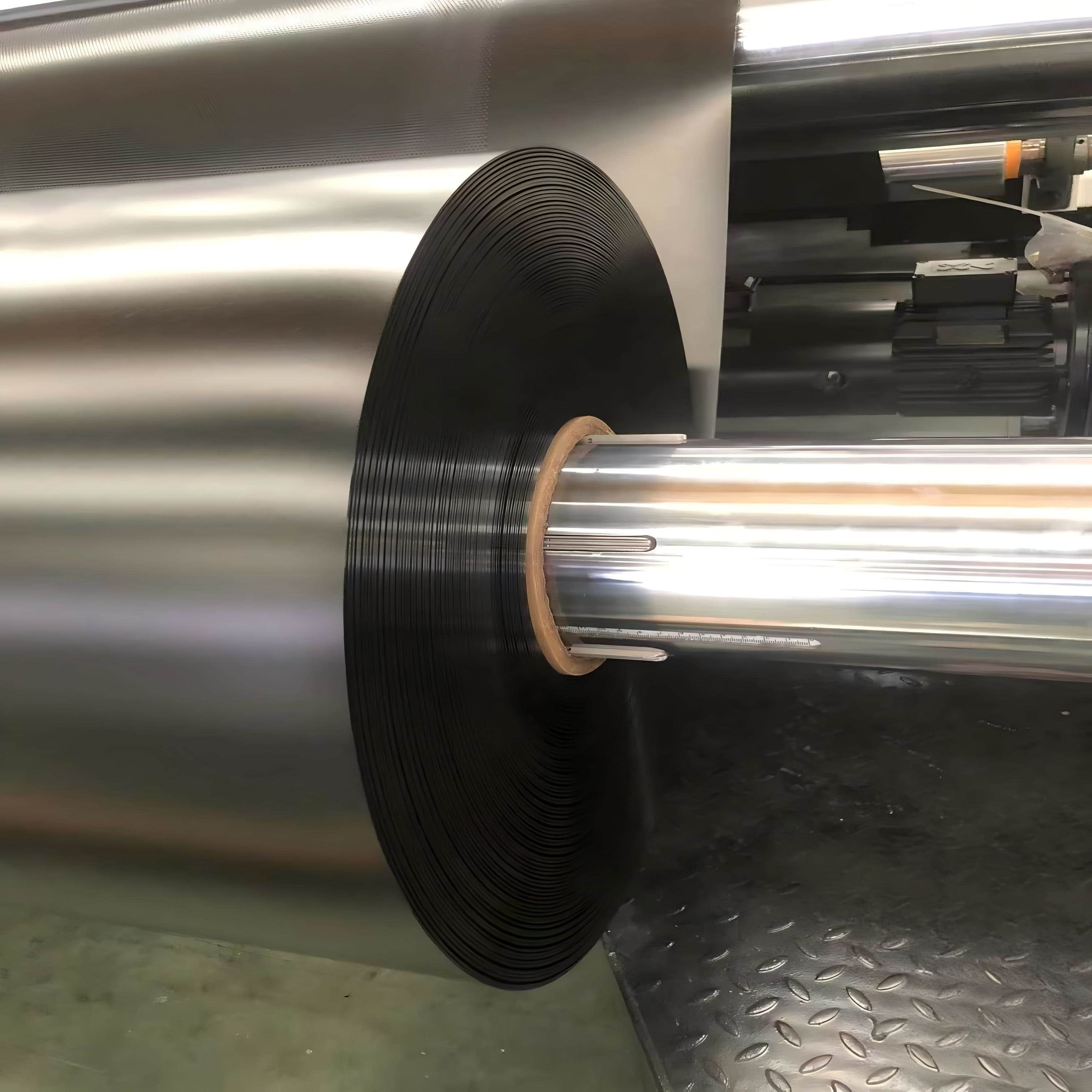

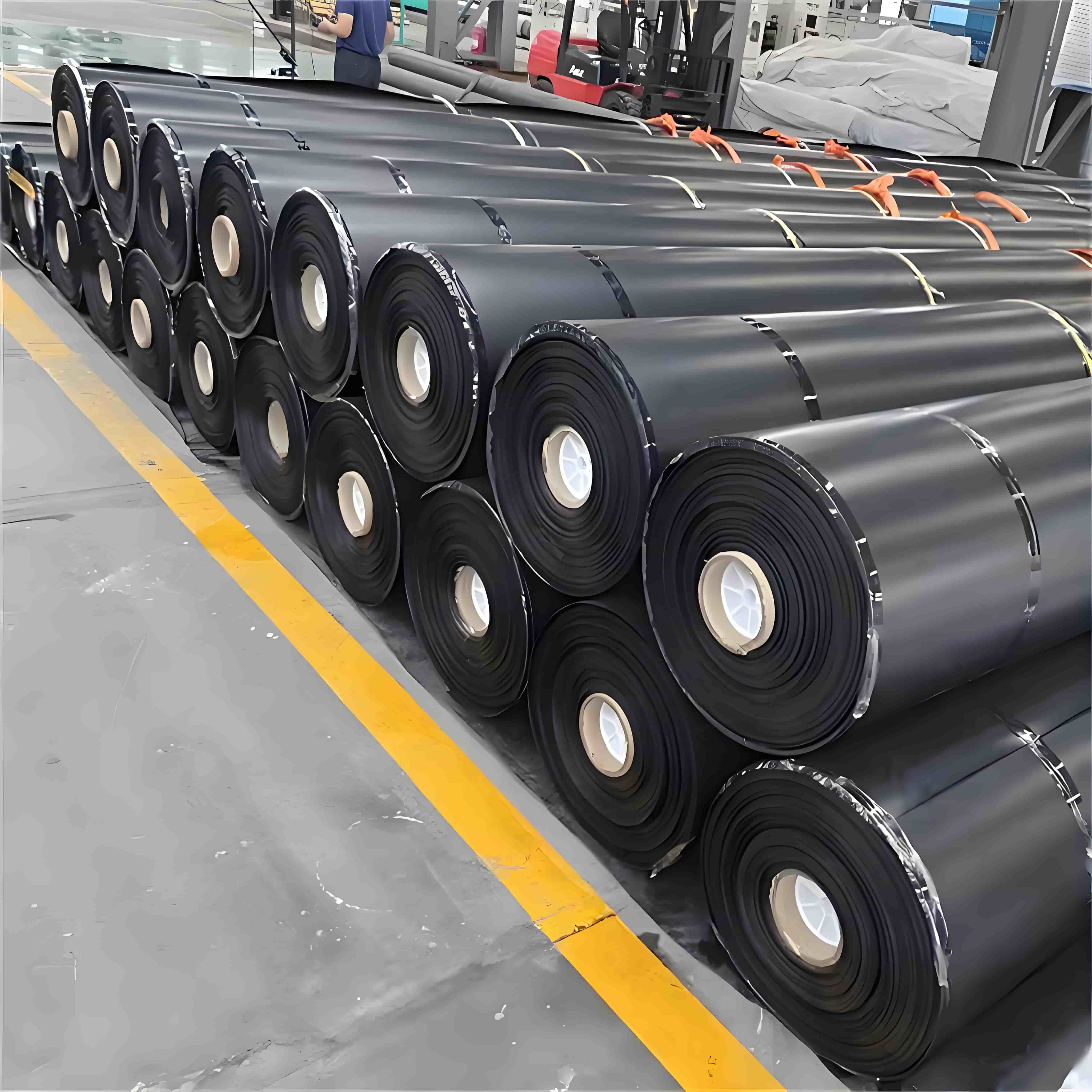

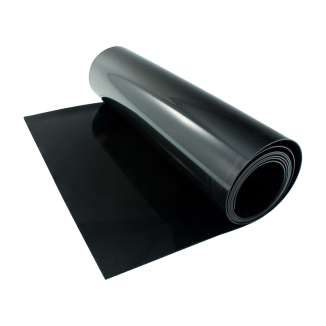

HDPE Liner Sheet is a sheet - shaped lining material made from high - density polyethylene resin as the main raw material through processes such as extrusion and calendering.Its molecular structure is compact and has a high degree of crystallinity, endowing the following core characteristics:

Physical properties: High density (0.941 - 0.965g/cm³), strong hardness, high tensile strength, and excellent impact resistance (it can maintain toughness even in low - temperature environments).

Chemical stability: Resistant to corrosion by various chemical media such as acids, alkalis, and salts, with strong resistance to the penetration of organic solvents, and suitable for harsh chemical environments.

Weather resistance: Resistant to ultraviolet (UV) radiation, resistant to aging, and can be exposed to outdoor environments for a long time; after adding antioxidants to some products, the service life can reach more than 20 years.

Environmental friendliness: Non-toxic and odorless, compliant with food contact material standards (such as FDA certification), and applicable to scenarios like drinking water tanks and food storage tanks.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

Water Conservancy and Aquaculture:Anti - seepage lining of reservoirs, ponds and rivers; anti - seepage and anti - corrosion of aquaculture ponds to maintain stable water quality.

Industrial storage tanks:Linings for chemical storage tanks and acid-alkali storage tanks prevent media leakage and tank corrosion; food-grade HDPE lining boards are used for edible oil and beverage storage tanks.

Water Conservancy and Aquaculture:Anti - seepage lining of reservoirs, ponds and rivers; anti - seepage and anti - corrosion of aquaculture ponds to maintain stable water quality.

Constructional Engineering:Basement moisture-proof layer, tunnel anti-seepage lining, anti-corrosion lining board for waste incineration plant equipment.

Agriculture and Gardening:Seepage prevention of irrigation canals, linings of biogas digesters, seepage prevention of artificial lakes to improve water resource utilization; moisture-proofing of nursery greenhouse floors.