Woven And Non Woven Geotextile

1. Category complementarity: Woven type has high tensile strength (suitable for reinforced load-bearing), non-woven type has excellent permeability (suitable for filtering and drainage), and can be combined and covered in multiple scenarios as needed.

2. Strong durability: all adopt anti-aging materials, woven with tear resistance, non-woven with abrasion resistance, and adapt to complex environments such as acid, alkali, humidity, etc.

3. Flexible construction: Machine woven fabric is easy to cut and splice, non-woven fabric fits the terrain, lightweight and can be manually laid, compatible with multiple engineering processes.

4. High cost-effectiveness: covering temporary to permanent engineering needs, factory direct supply offers excellent prices, reducing material waste and post maintenance costs.

Products Introduction:

Woven and Non Woven Geotextile are two mainstream geosynthetic materials, both made from high molecular weight fibers such as polypropylene (PP) and polyester (PET), which complement each other due to differences in processing techniques. Woven geotextile is interwoven with warp and weft yarns, emphasizing high strength and structural stability; Non woven geotextiles use processes such as needle punching and thermal bonding to randomly arrange and solidify fibers, with a focus on permeability and filtration. The two types of products jointly cover the four major engineering requirements of "reinforcement, filtration, drainage, and isolation", and are suitable for diverse scenarios from roadbed reinforcement to water conservancy protection. They are one of the most widely used basic materials in civil engineering, with both functionality and economy, providing flexible material choices for different engineering scenarios.

Product Features:

(1) Woven Geotextile

High strength tensile resistance: The warp and weft yarns are tightly interwoven, and the longitudinal/transverse tensile strength can reach 20-100kN/m. It has excellent tear resistance and creep resistance, and can effectively disperse loads. It is suitable for scenarios that require strong reinforcement, such as high fill roadbeds and retaining walls.

Structural stability and wear resistance: The fabric has a regular texture, high surface strength, and can withstand heavy machinery rolling and sharp object friction. It is not easily deformed under long-term loads and has a service life of 10-20 years.

Controllable permeability: By adjusting the yarn density to control the pore size, it can not only meet the basic drainage needs, but also reduce excessive water infiltration in specific scenarios (such as isolation layers), balancing protection and drainage functions.

(2) Non Woven Geotextile

Efficient filtration and drainage: The fibers are randomly arranged to form a three-dimensional porous structure with uniform pores (0.05-0.3mm), and the fine soil retention rate exceeds 95%. At the same time, the permeability coefficient is ≥ 1 × 10 ⁻ cm/s, which can quickly divert water and prevent soil loss and piping.

Strong flexibility and adhesion: The texture is soft and can bend with the terrain, closely adhering to irregular base layers (such as slopes and ditches), adapting to small settlement deformations, and avoiding local failures caused by uneven laying.

Lightweight and easy to construct: With a weight of 50-400g per square meter, it is easy to cut and can be manually laid without the need for professional equipment. The overlap width is ≥ 10cm to ensure integrity, and the construction efficiency is 30% higher than that of woven geotextiles.

(3) Common advantages of two types of products

Weather resistance and corrosion resistance: All have been treated with UV resistance and acid alkali resistance, and can be stably used in environments ranging from -30 ℃ to 70 ℃, resisting soil corrosion and microbial erosion.

Ecological compatibility: using environmentally friendly raw materials, non-toxic and harmless, can work synergistically with vegetation (such as non-woven fabrics providing attachment carriers for grass seeds), and does not damage the ecological environment.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

(1) Typical Applications of Woven Geotextiles

Roadbed and pavement reinforcement: laid in high fill roadbeds of highways and railways to enhance the shear strength of the roadbed and reduce settlement deformation; Combined with the asphalt layer, it disperses vehicle loads and reduces the risk of pavement cracking.

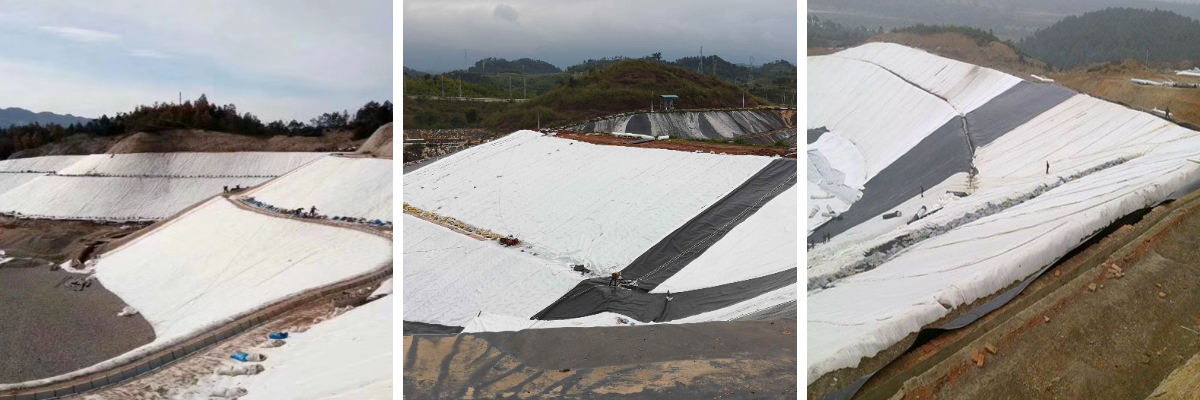

Reinforcement of retaining walls and slopes: used to reinforce the reinforcement layer of soil retaining walls, which works in conjunction with backfill soil to enhance the wall's resistance to overturning; Lay on steep slopes (slope>45 °) to prevent landslides and collapses.

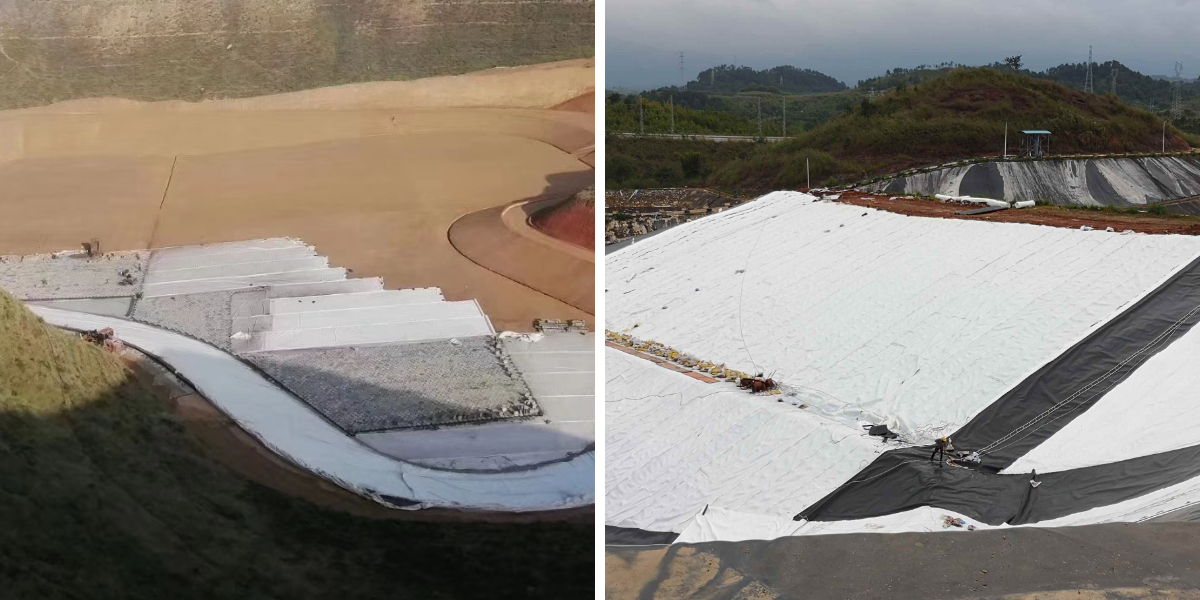

Dam and channel protection: laid on the upstream slope of the dam to resist water flow erosion and wave impact, and protect the dam structure; Use the bottom of the hard channel as an isolation layer to reduce mixing between the channel and the foundation soil material.

(2) Typical applications of non-woven geotextiles

Filtration and drainage engineering: Wrap drainage pipes or infiltration ditches to filter sediment and prevent blockage; As an anti filter layer in the landfill site, it isolates the garbage from the surrounding soil and diverts the leachate.

Slope and river ecological protection: laid on the surface of vegetation slopes, intercepting soil particles, and cooperating with spraying greening to prevent soil erosion; As an ecological foundation, the riverbank provides a growing environment for aquatic plants.

Temporary engineering and agricultural field: serving as the grassroots of temporary construction access roads, rapidly improving the site's carrying capacity; Laying in farmland drainage ditches, filtering water flow to protect canal walls and reduce irrigation losses.

(3) Collaborative application scenarios

In complex engineering, two types of products are often used in combination: for example, "woven geotextile (reinforced)+non-woven geotextile (filtered)" is used for high-grade highway subgrade, with the woven layer enhancing load-bearing capacity and the non-woven layer filtering drainage, forming a "reinforced filter drainage" dual protection system.

Woven And Non Woven Geotextile has the core advantage of "complementary functions and full scene coverage". Woven geotextiles meet structural reinforcement requirements with high strength, while non-woven geotextiles rely on efficient filtration and flexibility to adapt to ecological protection, jointly building the "basic protection network" of civil engineering. Whether it is structural reinforcement for heavy engineering or soil and water conservation for ecological projects, both types of products can provide targeted solutions through individual or combined applications. It has strong weather resistance, convenient construction, and controllable cost, which can ensure the safety and stability of the project and meet the needs of green construction. It is an ideal material choice for "efficient, reliable, and sustainable" in modern civil engineering, promoting the balance between functionality and economic value of various projects.