Subgrade Geotextile

1. High strength: Excellent tensile, tear, burst, and puncture resistance.

2. Corrosion resistance: Made of synthetic fibers, it is resistant to acid, alkali, microorganisms, and insect infestations, and has good durability.

3. Permeability: It has good permeability and can effectively drain and filter water.

4. Easy construction: lightweight, easy to cut, transport, and lay, can greatly improve construction efficiency.

5. High cost-effectiveness: The material cost is relatively low and can reduce the use of traditional materials such as stone and sand, thereby lowering the overall project cost.

Product Introduction:

Subgrade Geotextile is a permeable geosynthetic material made from synthetic fibers such as polypropylene, polyester, nylon, etc., through processes such as needle punching or weaving. It is essentially "fabric used in civil engineering" and is the most widely used and fundamental type of geosynthetic material in geotechnical engineering.

Main functions

Geotextiles play four key roles in engineering:

1. Separation

Function: Separate two types of geotechnical materials with different physical properties (such as gravel and soft soil) to prevent them from mixing with each other.

Example: Laying geotextile between railway ballast and soft soil foundation can prevent the ballast from sinking into the soft soil, and also prevent the soft soil from rising and contaminating the ballast, maintaining their respective structural integrity and functionality.

2. Filtration

Function: While allowing liquid (water) to pass vertically, prevent excessive loss of soil particles. It serves as a 'sieve'.

Example: Used in the drainage layer behind drainage ditches and retaining walls, allowing water flow to be smoothly discharged while preventing soil particles from being carried away by water flow and avoiding the foundation or structure from being hollowed out.

3. Drainage

Function: Utilize the pore channels inside the geotextile to discharge liquid (or gas) along its plane direction, collect and guide water flow.

Example: Used for the interior of earth dams and underground drainage systems, guiding water to collection pipelines to reduce groundwater level or pore water pressure.

4. Reinforcement

Function: Utilizing its high tensile strength and friction with the soil, it disperses loads, improves the strength and stability of the soil, similar to steel bars in concrete.

Example: Used to reinforce roads, embankments, and steep slopes on soft soil foundations to prevent foundation cracking and slippage.

Additional function: Protection - Geotextile can serve as a buffer layer to protect other waterproof materials (such as geomembranes) from being pierced by sharp stones or hard objects.

Main types

According to different manufacturing processes and structures, geotextiles are mainly divided into two categories:

Manufacturing process: It is mainly composed of short fibers or long fibers arranged randomly and reinforced by mechanical needling, thermal bonding, or chemical bonding methods.

Features: It looks like felt, isotropic (with similar properties in all directions), and has good extensibility and deformation adaptability. More emphasis is placed on isolation, filtration, and drainage functions.

Common applications: roadbed isolation, drainage system, landfill filter layer, erosion control, etc.

Manufacturing process: Woven from fiber filaments or flat strips in a certain direction on a loom, with a structure similar to burlap.

Features: Regular pores, high tensile strength, low elongation. More emphasis is placed on reinforcement and protective functions.

Common applications: reinforcing soft soil foundations, reinforcing retaining walls, dam reinforcement, coastal protection, etc.

Other types: Knitted geotextiles, composite geotextiles (non-woven fabric and geomembrane composite, etc.), used to meet more specific engineering needs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

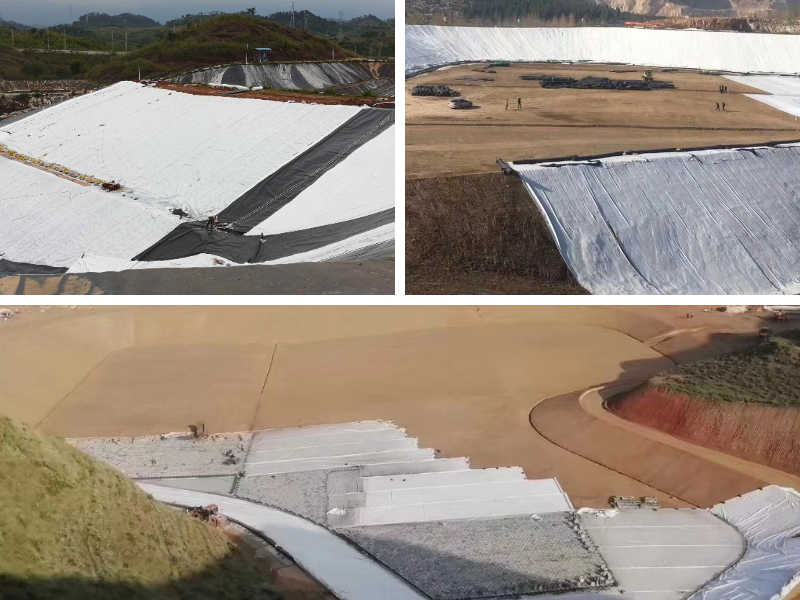

Product Applications:

1. Water conservancy engineering

Dam engineering: used as a filter layer for dams to prevent soil particles from flowing away with water flow, while discharging seepage water and enhancing dam stability; It can also serve as a protective layer for embankment slopes, resisting water flow erosion.

River regulation: laid on the bank slope of the river to prevent erosion of the riverbank by water flow and protect the embankment; After dredging or dredging the river channel, it is used for isolation and reinforcement of the riverbed to avoid mixing of sediment.

Reservoir engineering: As the filtering layer and drainage layer of the reservoir dam body, it controls the seepage path and reduces the risk of seepage deformation of the dam body; Combined with geomembrane for anti-seepage in storage areas and enhancing puncture resistance.

2. Transportation Engineering

Highway construction:

Roadbed treatment: Lay geotextile between the roadbed and the pavement to isolate different soil layers (such as clay and sand), prevent the roadbed soil from softening after being soaked in water, and enhance the bearing capacity of the roadbed.

Road maintenance: When renovating old road surfaces, lay geotextiles to reduce reflection cracks and extend the service life of the road surface; It can also be used for reinforcing temporary access roads to facilitate the passage of construction vehicles.

Railway engineering: used for reinforcing and isolating railway roadbeds, reducing the impact of train loads on roadbed settlement, preventing the loss of track base materials, and ensuring track stability.

Airport engineering: In the foundation treatment of airport runways and aprons, reinforcement and filtering are used to improve the bearing capacity of the foundation and resist the impact loads of aircraft takeoff and landing.

3. Municipal and Construction Engineering

Municipal drainage: Lay geotextile around underground drainage pipes as a filtering layer to prevent soil particles from blocking the pipes, and guide groundwater into the pipes to avoid water accumulation.

Building foundation: Used for isolation and drainage of building foundations, especially in soft soil foundation treatment, to help drain water from the foundation, accelerate soil consolidation, and reduce settlement.

Landfill site: As an anti-seepage auxiliary material for landfills, it is used in combination with geomembranes to prevent soil and groundwater pollution caused by leachate from garbage; Simultaneously serving to isolate garbage from the underlying soil and filter leachate.

4. Environmental Protection and Ecological Engineering

Soil and Water Conservation: Laying geotextiles on slopes (such as highway slopes and mine reclamation areas), combined with vegetation planting, to prevent soil erosion caused by rainwater erosion and promote ecological restoration.

Artificial wetland: used for isolation and filtration at the bottom of wetlands to prevent the loss of wetland substrates (such as sand, gravel, and soil), while ensuring water infiltration and purification functions.

Wastewater treatment: In facilities such as sedimentation tanks and filtration tanks in wastewater treatment plants, suspended particles in water are separated as filter media.

5. Mining Engineering

Mine tailings treatment: laid on the tailings dam body or bottom as a filter layer and isolation layer to prevent tailings particle loss, control leachate pollution, and enhance dam stability.

Tunnel support: Lay geotextile on the surface of the surrounding rock of the mine tunnel, combined with shotcrete and other processes, to enhance the integrity of the surrounding rock and prevent rock collapse.

6. Agriculture and Horticulture

Irrigation system for farmland: used for anti-seepage and protection of irrigation channels in farmland, reducing channel leakage and preventing water flow from eroding channel slopes.

Horticultural engineering: In the planting of flowers and seedlings, geotextiles are laid to isolate the soil from coverings (such as bark and stones), prevent weed growth, and maintain soil permeability.

In short, geotextiles play a crucial role in various civil engineering, environmental engineering, and agricultural fields due to their excellent physical and mechanical properties and diverse functions. They are one of the indispensable materials in modern engineering construction.