Cement Blanket Suppliers

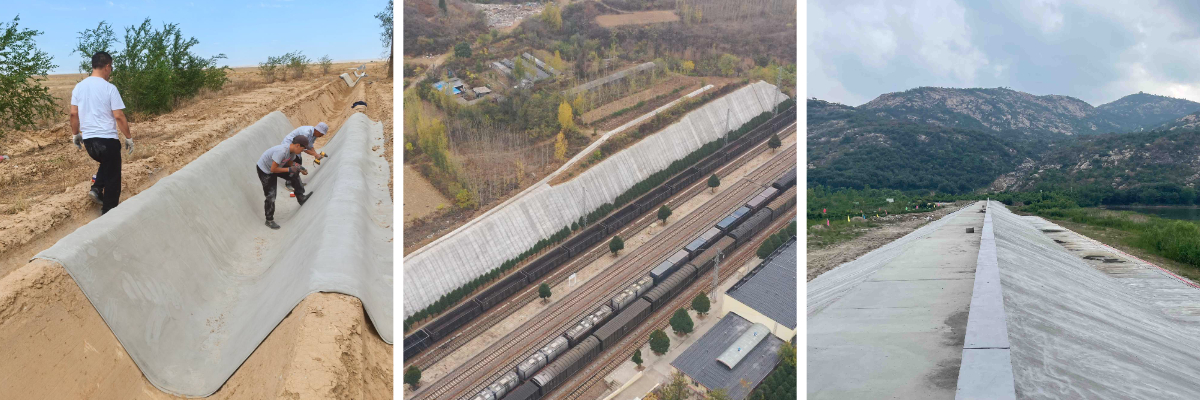

Product Introduction: This innovative composite material merges the pliability of textiles with the structural integrity of cement. It can be rapidly deployed and cures into a resilient concrete surface.

Eco-Friendly & Energy Efficient: It eliminates material waste and achieves a reduction exceeding 90% in carbon emissions compared to conventional methods.

Exceptional Longevity: Resists damage from freeze-thaw cycles, chemical corrosion, abrasion, hydraulic scouring, and exposure to seawater or sewage. It also withstands UV degradation, offering a service life of up to 50 years.

High-Speed Installation: Requires no specialized machinery and can be installed by a single operator. Application is 10 times faster than traditional concrete pouring. The rapid-setting material is supplied in rolls or bulk quantities, optimizing transport, handling, and placement.

Superior Adaptability: Can be easily cut on-site to fit intricate contours and complex landscapes. It also supports vertical or overhead applications.

1. Product Introduction

Cement Blanket Suppliers, also known as “concrete cloth” or “cement fabric,” is an innovative construction material designed to simplify and accelerate the process of creating durable, hard-wearing surfaces. It combines the flexibility of a textile with the strength of concrete, offering a lightweight, easy-to-install alternative to traditional concrete.

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Composition: The core structure of a cement blanket consists of three layers: a top layer of polypropylene (PP) fabric for protection, a middle layer pre-impregnated with dry cement and sand, and a bottom layer of polyethylene (PE) film to prevent water seepage. This composite design ensures both durability and adaptability.

Working Principle: When hydrated with water, the pre-mixed cement in the middle layer activates and hardens, transforming the flexible fabric into a rigid, stone-like material within 24–48 hours. The curing process is self-contained, requiring no additional formwork or mixing on-site.

Key Advantages:

• Lightweight & Portable: Weighs approximately 15–25 kg per square meter (vs. traditional concrete’s 2,400 kg/m³), making it easy to transport and handle.

• Rapid Installation: Can be cut, folded, or shaped to fit irregular surfaces in minutes, reducing labor and project time by up to 80% compared to conventional concrete pouring.

• Cost-Effective: Eliminates the need for heavy machinery, formwork, or skilled labor, lowering overall construction costs.

• Environmentally Friendly: Reduces cement waste and carbon emissions due to its pre-mixed, precision-engineered formula.

2. Application Scenarios

Cement blankets are widely used in various industries where quick, reliable, and cost-efficient hard surfaces are required. Key applications include:

(1) Emergency Infrastructure

In disaster relief or emergency response (e.g., earthquakes, floods), cement blankets enable rapid construction of temporary roads, flood barriers, or shelter foundations. Their portability and quick hardening properties make them ideal for urgent projects with limited resources.

(2) Erosion Control

For slope stabilization, riverbank protection, or ditch lining, cement blankets form a continuous, erosion-resistant layer that adheres to uneven terrain. They prevent soil loss and water damage in agricultural, mining, or environmental restoration projects.

(3) Construction & Civil Engineering

• Temporary Flooring: Used as temporary walkways, parking areas, or construction site access roads, reducing wear on natural ground.

• Underground Utilities: Applied as protective covers for pipelines, cables, or drainage systems, ensuring long-term durability against soil pressure and moisture.

(4) Landscaping & Recreational Facilities

Cement blankets are used to create decorative pathways, patio edges, or small retaining walls in gardens, parks, or sports facilities. Their flexibility allows for curved or custom shapes, enhancing aesthetic design without compromising strength.

(5) Military & Remote Operations

In remote or off-grid locations (e.g., military bases, mining camps), cement blankets provide a practical solution for building helipads, storage areas, or defensive barriers with minimal logistical support.

3. Conclusion

Cement blankets represent a breakthrough in construction materials, merging the benefits of textiles and concrete to address challenges in speed, cost, and adaptability. Their diverse applications across emergency, civil, and industrial sectors make them a versatile choice for modern infrastructure development.