Cement Curing Blankets

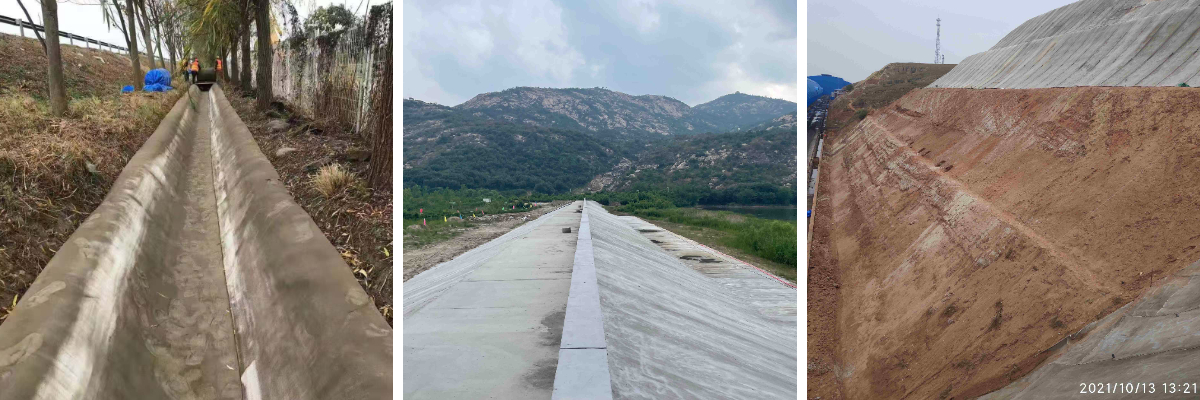

1.Fast and easy laying:

The product is in a rolled shape and can be directly laid on the construction surface like a carpet. It does not require traditional processes such as formwork and vibration, and can be operated by a single person.

2.High strength and durability:

After curing, the compressive strength can reach 20-30MPa, and the flexural and crack resistance performance is better than that of ordinary concrete. It has strong weather resistance and a service life of more than 20 years.

3.Strong adaptability to terrain and scenarios:

It can be bent and laid according to complex terrains such as slopes and ditches with high fitting degree. It is suitable for scenarios such as river slope protection, canal seepage prevention, and subgrade cushion, especially for irregular base construction.

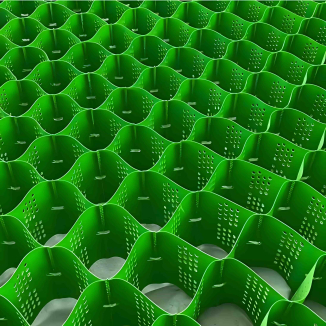

Product Introduction:

Cement Curing Blankets are a composite material consisting of a three-dimensional fibrous fabric (e.g., polypropylene or polyester) embedded with rapid-setting specialty cement. The fabric acts as a reinforcing matrix, uniformly impregnated with the cement to form a flexible, rollable sheet. Upon hydration during installation, the cement undergoes a hardening reaction, curing within 24 hours into a high-strength concrete layer that combines the flexibility of fabric with the rigidity of concrete.

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Product Applications:

1.Hydraulic Engineering:

Riverbank slope protection, canal seepage prevention, dam reinforcement, drainage pipeline repair.

2.Transportation Engineering:

Temporary road paving, subgrade cushion, tunnel waterproofing, slope protection.

3.Environmental Protection and Emergency Engineering:

Debris flow prevention, rapid construction of flood control dams, mine wound coverage.

4.Landscape and Civil Scenarios:

Courtyard walkways, small pool construction, simple drainage ditch construction.

With "rapid, flexible, and versatile" as its core advantages, the concrete blanket fills the application gaps of traditional concrete in emergency rescue, complex terrains, and small - scale projects. However, it cannot replace the role of traditional concrete in large - scale structural projects. The two need to be selected complementarily according to project requirements (such as strength, construction period, and terrain) to jointly serve the construction and infrastructure fields.