Woven Drainage Fabric

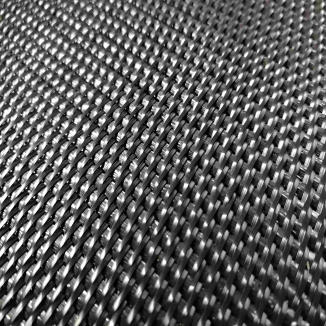

1.High structural strength: Warp and weft weaving technology provides strong tensile and tear resistance, withstands loads, and resists breakage.

2.Precise filtration and drainage: Uniform and stable pores filter sediment and prevent clogging, ensuring smooth drainage.

3.Durable and aging-resistant: Tightly constructed, UV-resistant, acid- and alkali-resistant, extending lifespan by 2-3 years.

4.Widely adaptable: Customizable specifications, high flatness, easy alignment, and efficient installation.

Product Introduction

I. Basic Properties

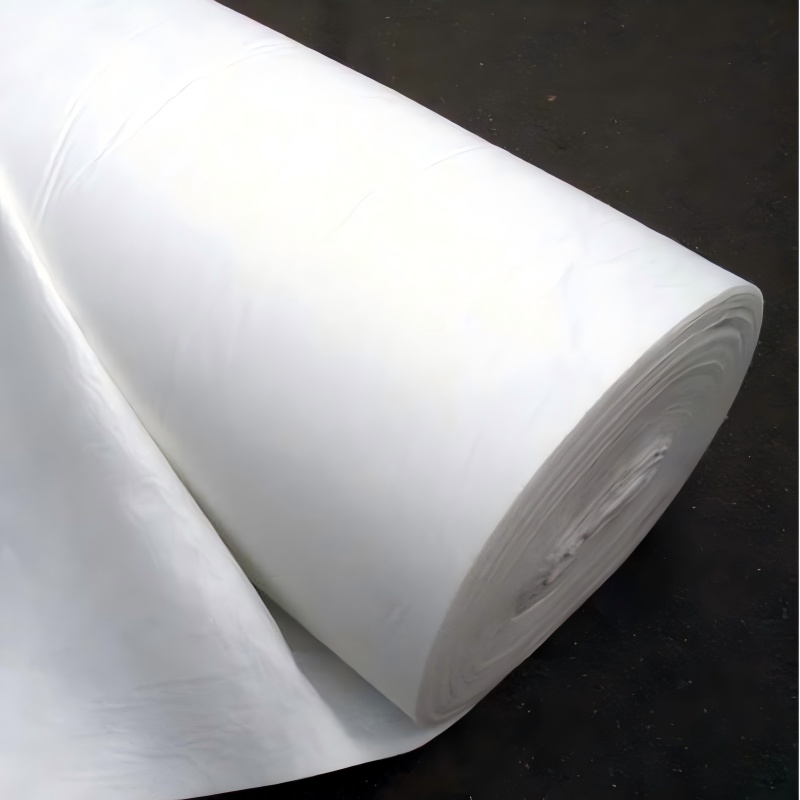

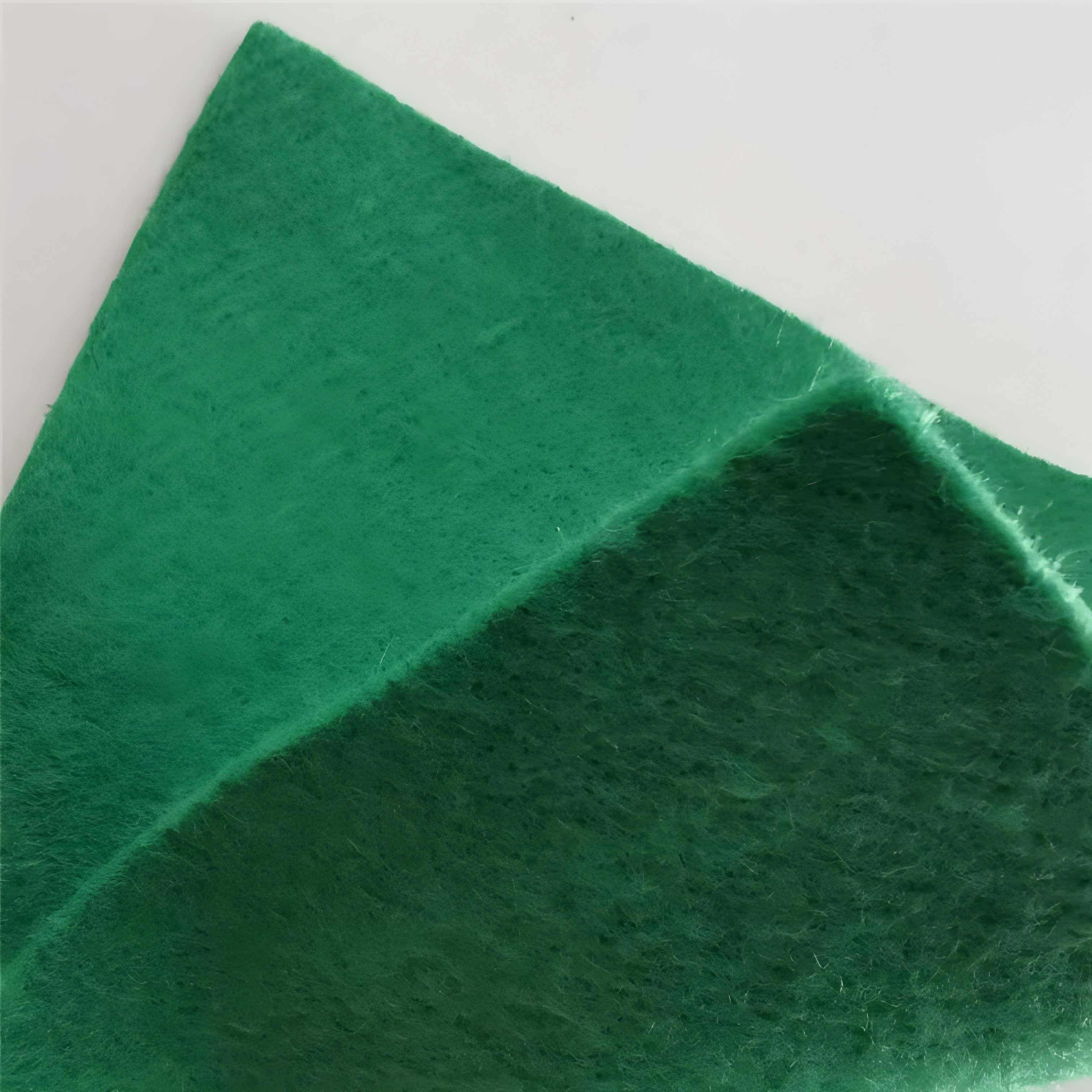

Material and Processing: Woven Drainage Fabric is made from high-molecular-weight polyethylene or polypropylene using a weaving process that interweaves warp and weft threads, resulting in a tight and regular fabric structure.

Physical Properties: Customizable width and thickness are available, resulting in high flatness and a single roll weight suitable for construction and handling. It combines flexibility with structural stability.

Environmental Compatibility: UV- and corrosion-resistant treatment ensures strong weather resistance, making it suitable for common construction environments such as open-air and flooded areas.

II. Core Functions

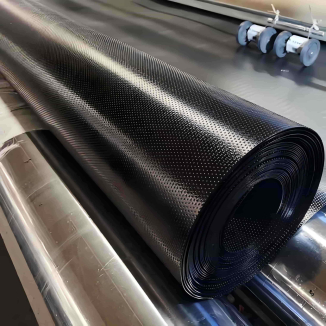

Filtration and Drainage: Its uniform and stable pores trap fine soil particles, preventing drainage channel blockage while maintaining a smooth water flow path and efficiently channeling excess water from the soil or project.

Structural Protection: Its high tensile and tear strength withstands construction loads and soil pressure, reducing frictional damage to the underlying substrate (such as geomembranes and blind pipes) caused by external forces, thereby ensuring structural stability.

III. Main Features

Significant Strength Advantage: The weaving process imparts mechanical properties far superior to nonwovens, resulting in strong resistance to damage and deformation, making it suitable for high-load construction scenarios.

Outstanding Durability: The compact structure combined with anti-aging treatment provides excellent resistance to UV rays, acids, and alkali corrosion, extending its service life by 2-3 years compared to ordinary drainage fabrics, reducing ongoing maintenance costs.

Flexible Adaptability: Customizable specifications, high flatness, and easy integration with other construction materials make it suitable for diverse construction environments such as bridges, dams, and landfills, ensuring efficient installation.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1. Transportation Infrastructure

Highway/Railway Subgrade: Paved between the subgrade soil and the cushion layer, it withstands subgrade loads with its high tensile strength, preventing deformation and damage. Its uniform porosity also filters sediment and channels groundwater, preventing subsidence and cracking caused by softening water in the subgrade, thus ensuring long-term road stability.

Bridge Cap/Tunnel: Paved at the interface between the backfill layer of bridge caps and tunnel sidewalls and the soil, it resists backfill pressure and reduces frictional damage to the structure. It also quickly drains surrounding water, preventing erosion of bridge piers and tunnel linings, thereby extending the life of the infrastructure.

2. Water Conservancy Engineering

Dyke/River Slope: Applied outside the anti-seepage layer of dykes or within river slope protection structures, its tightly woven structure resists water erosion, traps soil particles on the slope, and prevents soil erosion. It also effectively channels seepage within the dyke, reducing the risk of piping and landslides, making it suitable for harsh environments involving long-term water wading.

Artificial Lakes/Reservoirs: Layed above the impermeable membrane at the bottom of the lake or reservoir bank, it protects the membrane from damage caused by sharp sand and gravel while also channeling accumulated water, preventing damage to the membrane due to excessive water pressure and ensuring safe water storage.

3. Environmental Engineering

Landfills: Layed between the impermeable membrane and the protective layer within the bottom impermeable system of the landfill. Its high strength withstands the load of garbage compaction while filtering solid impurities from the leachate, preventing blockage in drainage blind pipes and ensuring efficient leachate collection, thereby reducing soil contamination.

Sewage Treatment Plants: Used as a drainage layer around sedimentation tanks and filtration ponds. Its stable pores filter suspended solids from wastewater, preventing siltation in drainage channels. It is also resistant to acid and alkali corrosion and adaptable to the chemical environment of sewage treatment plants.

4. Construction Engineering

Building foundation pits: Laid within the slope support layer of the foundation pit, its high tear strength resists slope soil pressure and prevents deformation of the support structure. It also rapidly drains seepage from the foundation pit, reducing soil moisture content, preventing pit collapse, and ensuring construction safety.

Underground garage roofs: Laid between the roof backfill layer and the waterproofing layer, it protects the waterproofing layer from friction damage from the backfill soil while channeling rainwater and groundwater, preventing roof leakage and improving the waterproofing and moisture-proofing of the underground space.

Woven drainage fabrics, with their core advantages of high structural strength, precise filtration and drainage, and exceptional durability, play a key role in four core engineering fields: transportation, water conservancy, environmental protection, and construction. They can address specific challenges in different scenarios, such as load bearing, water diversion, and structural protection, ensuring the safety and long-term stability of engineering structures. They are adaptable to diverse and complex environments, providing strong support for efficient construction and low maintenance costs in various projects, making them a crucial material for modern engineering, combining functionality and reliability.