Membrane HDPE

1. Super weather resistance: UV resistance, high and low temperature resistance (-60 ℃ to 80 ℃), acid and alkali corrosion resistance, outdoor service life of over 50 years.

2. Excellent anti-seepage: high molecular density, permeability coefficient ≤ 10 ⁻¹¹ cm/s, zero leakage of liquid and gas, suitable for harsh anti-seepage scenarios.

3. Flexible construction: The material is lightweight and weldable, with a joint strength of over 80% of the base material, and can be quickly laid in complex terrains.

4. Economic durability: Long term maintenance free one-time laying, with a comprehensive cost 30% lower than traditional materials, and no major maintenance expenses in the later stage.

Products Introduction:

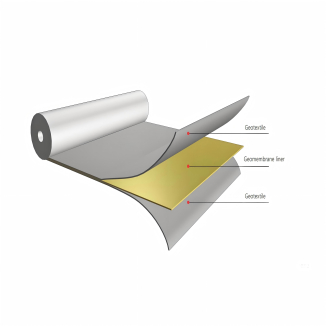

Membrane HDPE (high-density polyethylene anti-seepage film) is a flexible waterproof material mainly made of high-density polyethylene and processed by special technology. It has a very high molecular density, a dense and uniform structure, retaining the flexibility of polyethylene material while possessing excellent mechanical strength and chemical stability. This type of membrane material mainly serves important functions such as anti-seepage, isolation, and protection in civil engineering, environmental protection, and water conservancy. It can effectively prevent the permeation and diffusion of liquids and gases, providing reliable guarantees for the safe and stable operation of various projects.

Product Features:

1. Outstanding weather resistance: It has excellent UV resistance and is not prone to aging or cracking even in long-term direct sunlight environments. It can adapt to extreme temperature environments, maintain stable performance within the temperature range of -60 ℃ to 80 ℃, and will not become brittle or soften due to drastic temperature changes. At the same time, it has good corrosion resistance to acids, bases, organic solvents, etc., and can be used for a long time in various complex chemical environments. Its outdoor service life can exceed 50 years.

2. Excellent and reliable anti-seepage effect: Thanks to its extremely high molecular density, its permeability coefficient is extremely low, ≤ 10 ⁻¹¹ cm/s, almost achieving zero leakage of liquids and gases. Whether it is clean water, sewage, chemical solutions, or harmful gases, they are difficult to penetrate the membrane and can effectively block the permeation path. They are particularly suitable for harsh scenarios such as landfills, chemical wastewater treatment tanks, and hazardous material storage areas that require extremely high anti-seepage requirements.

3. The construction process is flexible and efficient: the texture is lightweight, the area of a single film is large, and it is easy to transport and lay, which can reduce the number of material splicing times during the construction process. The connection method adopts hot melt welding, and the joint strength can reach more than 80% of the base material, ensuring the integrity of the overall anti-seepage system. For complex terrains such as uneven terrain and multiple corners, flexible adaptation can also be achieved through cutting, welding, and other methods, greatly improving construction efficiency and shortening the construction period.

4. Economical, practical, and easy to maintain: After one-time installation, stable performance can be maintained for a long time without frequent maintenance and replacement, which can effectively reduce later operation and maintenance costs. Compared with traditional anti-seepage materials such as clay and asphalt, the comprehensive cost can be reduced by about 30%, and there is basically no major maintenance expenditure during use. It has both economy and durability, and can bring long-term economic benefits to the project.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Environmental protection field: In landfills, it can be used as an anti-seepage lining to prevent leachate from penetrating into soil and groundwater, avoiding environmental pollution; In hazardous waste disposal sites, harmful substances can be effectively isolated to prevent their spread and ecological damage.

2. Water conservancy engineering: suitable for anti-seepage treatment of reservoirs and dams, reducing water resource leakage losses; In the construction of artificial lakes and landscape water pools, it can serve as an impermeable layer to ensure water storage and maintain the landscape effect.

3. Municipal construction: used for anti-seepage of sedimentation tanks, oxidation tanks and other facilities in sewage treatment plants to prevent sewage leakage and pollution of the surrounding environment; In underground comprehensive pipe galleries, it can serve as a waterproof isolation layer to protect the pipe gallery structure from groundwater erosion.

4. Agriculture and Mining: Laying irrigation channels in farmland can reduce water resource infiltration waste and improve irrigation efficiency; In the tailings pond of a mine, it can serve as an anti-seepage layer to prevent harmful substances in the tailings slurry from infiltrating and polluting the soil and water sources.

Membrane HDPE, as a high-performance anti-seepage material, plays an irreplaceable role in many fields such as environmental protection, water conservancy, municipal engineering, agriculture, mining, etc. due to its super weather resistance, excellent anti-seepage effect, flexible and efficient construction method, and economic practicality. It can not only provide reliable anti-seepage guarantee for the project, effectively protect the ecological environment, but also reduce the overall cost of the project and reduce maintenance investment in the later stage. Whether it is a large-scale project or a small-scale project, membrane HDPE can meet the anti-seepage needs of different scenarios. It is a high-quality material that combines practicality and economy, with broad application prospects and promotion value.