Geomembrane Geotextile

1.Strong anti-seepage and strict pollution control: With a dense molecular structure and extremely low permeability, it can strongly block liquid infiltration and reduce the damage of pollutants to soil and groundwater from the source, which is the core guarantee of high anti-seepage requirements engineering.

2.High retention rate, protecting the ecology: During construction, there is minimal disturbance to the surrounding ecology, and solid materials can be efficiently retained.

3.Weather resistant and corrosion-resistant, durable: resistant to chemical erosion such as acid, alkali, and salt, adaptable to extreme temperature differences, and maintaining stable performance in complex environments.

4.Efficient construction and strong adaptability: lightweight and wide width, mature hot melt welding technology, firm joints and fast laying, able to adapt to working conditions such as foundation settlement, ensuring efficient progress and long-term safety of the project.

Product Introduction:

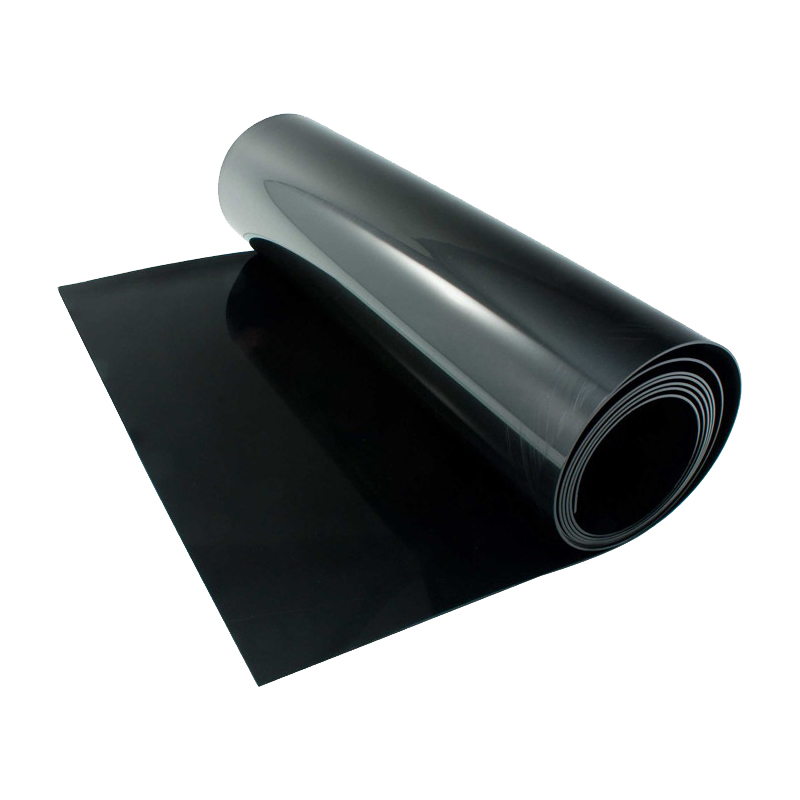

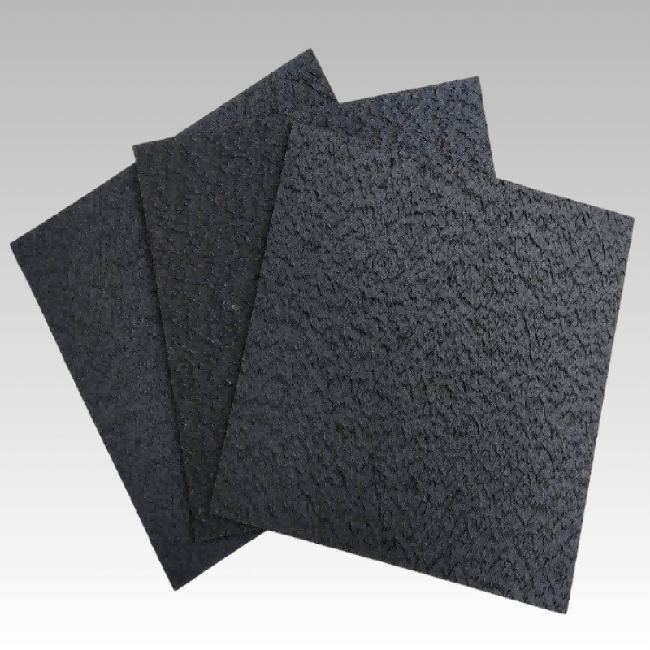

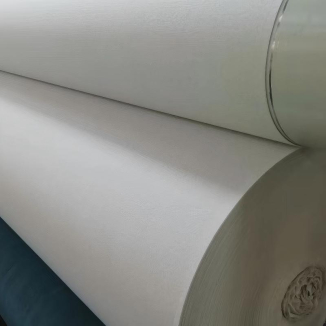

Geomembrane Geotextile, also known as high-density polyethylene geomembrane, is a type of anti-seepage and isolation geosynthetic material made mainly from high-density polyethylene resin through extrusion, blow molding and other processes. Its chemical stability is excellent, with high molecular density and crystallinity. The thickness is usually between 0.75mm and 3.0mm, and the width can reach 7 meters. It can be customized for production according to different engineering needs. HDPE geomembrane has a smooth surface or specific patterns, a flexible texture, and high strength. It can maintain good physical and chemical properties in various complex environments, providing reliable guarantees for the anti-seepage and isolation needs of engineering.

Product Features:

1.Excellent anti-seepage performance: HDPE geomembrane has a tight molecular structure, which can effectively prevent the leakage of harmful substances such as sewage and chemical solutions. It performs well in projects with extremely high anti-seepage requirements such as landfills and sewage treatment plants, greatly reducing the pollution risk of pollutants on soil and groundwater.

2.Excellent weather resistance and corrosion resistance: With excellent chemical stability, HDPE geomembrane has strong resistance to chemicals such as acid, alkali, and salt, and can be used for a long time in environments with different pH values without corrosion. At the same time, it can also adapt to extreme temperature conditions, maintaining good flexibility and mechanical properties regardless of whether it is high temperatures or extreme cold and low temperatures.

3.High strength and toughness: This geomembrane has high tensile strength and elongation at break, and can withstand significant tensile and deformation without breaking. During the construction process, even in the event of foundation settlement, soil deformation, etc., HDPE geomembrane can adapt to environmental changes with its high toughness, continuously play a protective role, and ensure the stability and safety of the project.

4.Convenient and efficient construction: HDPE geomembrane is lightweight, relatively easy to handle and lay, and can be connected through hot melt welding, extrusion welding, and other methods. The welding process is mature, the weld strength is high, the sealing is good, and it can quickly complete large-scale laying, effectively shortening the construction cycle. In addition, its wider width reduces the number of seams and further lowers the risk of leakage.

5.Outstanding environmental performance: HDPE geomembrane itself is non-toxic and odorless, and will not cause harm to the environment and human health. In engineering applications, it can effectively prevent the spread of pollutants and play a good role in environmental protection; At the same time, its production materials are recyclable and in line with the concept of sustainable development, making it a green and environmentally friendly geosynthetic material.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

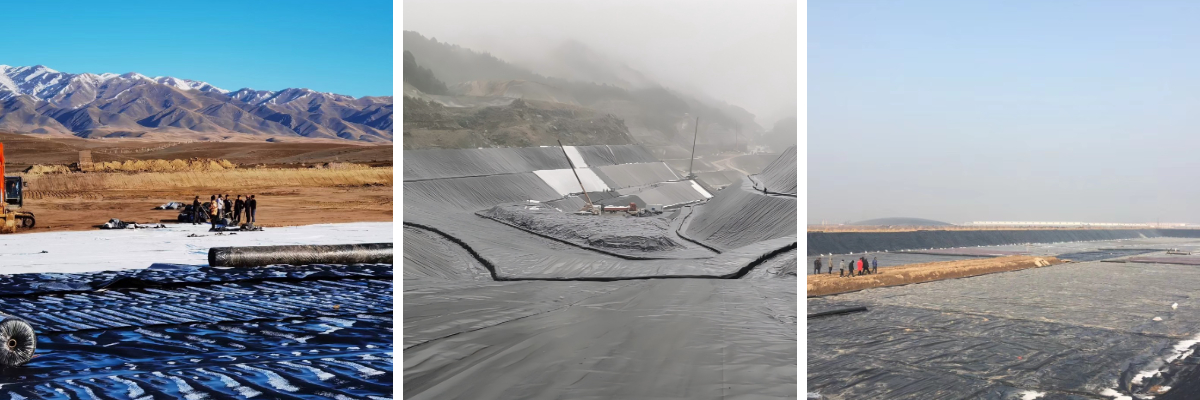

1.Water conservancy engineering: HDPE geomembrane is widely used for anti-seepage treatment in water conservancy projects such as reservoirs, dams, and canals. It can effectively prevent water leakage, improve the water storage capacity and operational safety of water conservancy facilities, reduce water resource waste, and avoid safety hazards such as dam collapse caused by leakage.

2.Landfill site: As the core material of the anti-seepage layer of the landfill site, HDPE geomembrane can block the leachate from garbage and prevent it from polluting the surrounding soil and groundwater. Combined with geotextile and other materials, a complete anti-seepage system is formed to ensure that the landfill site can effectively control pollution and protect environmental safety during operation and after closure.

3.Sewage treatment plant: HDPE geomembrane can prevent sewage leakage and avoid pollution to the surrounding environment in the regulating tank, oxidation pond, sludge tank and other parts of the sewage treatment plant. Its corrosion resistance and anti-seepage performance help maintain the stable operation of sewage treatment processes and improve sewage treatment efficiency.

4.Mining engineering: There are a large number of corrosive tailings and waste liquids in areas such as mine tailings ponds and heap leaching sites. HDPE geomembranes can be used as anti-seepage liners to prevent these harmful substances from infiltrating underground, protect the mining area and surrounding ecological environment, and also help to recycle useful components in tailings, improving resource utilization efficiency.

5.Agriculture:HDPE geomembrane can be used for anti-seepage and water retention in facilities such as agricultural irrigation reservoirs, artificial lakes, and aquaculture ponds, reducing water leakage losses and improving water resource utilization efficiency. In addition, in saline alkali land improvement projects, it can also serve to isolate salt and improve soil conditions, creating a favorable environment for crop growth.

6.Transportation engineering: HDPE geomembrane can be used to isolate groundwater in the construction of highway and railway subgrade, prevent settlement and deformation of the subgrade due to water immersion, and improve the stability and durability of the subgrade. In tunnel engineering, it can also serve as a waterproof board, effectively blocking groundwater and ensuring the safety and normal use of tunnel structures.

From this, it can be seen that HDPE geomembrane is an indispensable and important material in modern engineering construction. Its excellent performance and wide application prospects make it play an important role in promoting engineering quality improvement and environmental protection.