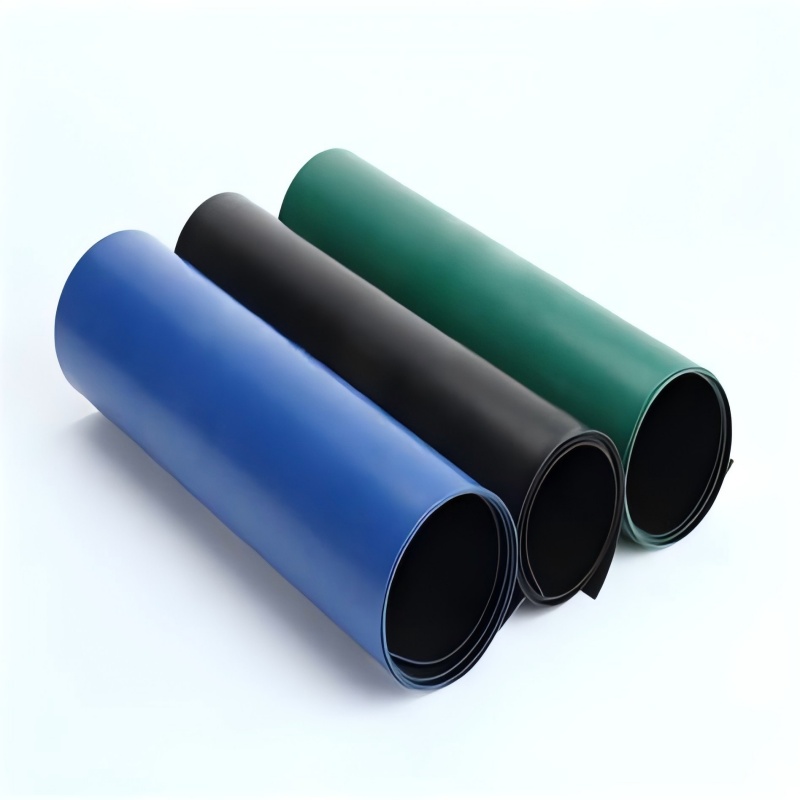

HDPE Geomembrane 1.5 mm

1.Excellent anti-seepage effect: The molecular structure is dense and the permeability coefficient is extremely low, which can effectively block the penetration of liquids and gases, far exceeding the anti-seepage ability of traditional materials such as clay.

2.Strong adaptability: It has high tensile strength and elongation, and can adapt to deformation caused by foundation settlement, temperature changes, etc. It is not easy to crack in low temperature environments and has stable performance at high temperatures.

3.Outstanding durability: acid and alkali resistance, corrosion resistance, anti-aging additives can resist natural erosion such as ultraviolet ray and oxidation, and reduce the later maintenance cost.

4.Convenient and efficient construction: With a lightweight texture, it can be prefabricated in the factory and quickly laid on site. Through hot melt/extrusion welding, it achieves tight splicing, suitable for large-scale projects, and shortens the construction period.

Product Introduction:

HDPE Geomembrane 1.5 mm is a kind of anti-seepage material made of high molecular polymer (such as HDPE, LDPE, LLDPE, PVC, EVA, etc.) as the main raw material. It has excellent permeability resistance, chemical corrosion resistance and aging resistance, and is widely used in anti-seepage projects in environmental protection, water conservancy, municipal, agriculture, mining and other fields.

Performance characteristics

1.Impermeability: Geomembranes have an extremely low permeability coefficient, such as HDPE geomembranes with a permeability coefficient of up to 1 × 10 ⁻¹⁷ cm/s, which can effectively prevent the infiltration of moisture, liquids, or gases and prevent leakage problems from occurring.

2.Mechanical properties: It has high tensile strength, tear resistance, and puncture resistance, can withstand certain external forces and foundation deformation, and is not easily damaged. For example, HDPE geomembrane has strong tensile strength and fracture elongation, and is suitable for uneven geological settlement with strong strain force.

3.Chemical stability: It is resistant to corrosion by chemical substances such as acid, alkali, and salt, and can maintain stable performance in various harsh chemical environments. It can be used for anti-seepage in chemical storage facilities, sewage treatment plants, and other places.

4.Aging resistance: additives such as anti-aging agent are added, which has good weather resistance and UV resistance. It can be exposed to the natural environment for a long time without obvious performance degradation. Its service life is long, generally up to about 50 years.

5.Low temperature resistance: It can maintain good flexibility and mechanical properties in low temperature environments, is not easily brittle, and can be used in engineering in cold regions.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1.Water conservancy engineering: used for anti-seepage treatment of reservoirs, dams, canals, artificial lakes, etc., to prevent water leakage, ensure water stability, and improve the safety and durability of the project.

2.Environmental protection engineering: anti-seepage liners and sealing covers for landfill sites, anti-seepage measures for water tanks, regulating tanks, oxidation ponds, etc. in sewage treatment plants, and anti-seepage isolation measures for hazardous waste treatment sites can effectively prevent soil and groundwater pollution caused by leachate and sewage from garbage.

3.Transportation engineering: As an anti-seepage isolation layer for highway and railway subgrades, it prevents groundwater from rising and causing damage to the subgrade, improving the stability and durability of the subgrade; It can also be used for waterproofing and moisture prevention in underground projects such as tunnels and subways.

4.Mining field: used for anti-seepage treatment of tailings ponds to prevent tailings wastewater leakage from polluting the surrounding environment; It can also be used for anti-seepage in washing tanks, heap leaching tanks, ash yards, etc.

5.In the field of agriculture, it is used for channel and reservoir anti-seepage in agricultural irrigation systems, as well as for lining anti-seepage in aquaculture ponds, lotus root ponds, shrimp ponds, etc. It can reduce water evaporation and leakage, improve water resource utilization efficiency, and provide a good environment for aquaculture.

6.Construction engineering: used for waterproofing and moisture prevention in basements, underground parking garages, rooftop gardens, planting roofs, etc., to prevent water infiltration and damage to building structures.

As a polymer based anti-seepage and barrier material, geomembrane plays a crucial role in various fields such as water conservancy, environmental protection, transportation, mining, and agriculture due to its excellent anti-seepage performance, outstanding mechanical and chemical stability, wide environmental adaptability, and convenient construction characteristics. It is an ideal anti-seepage solution that balances engineering safety, environmental protection needs, and economic costs.