Geo Fabric Material

1. Collaborative filtration and drainage: efficiently diverting accumulated water while intercepting fine soil, preventing blockages and ensuring long-term smooth drainage system

2. Flexible adaptation: Suitable for complex terrain without blind spots, suitable for various construction scenarios such as slopes and foundation pits

3. Weather resistant and corrosion-resistant: resistant to UV rays, acid and alkali erosion, stable performance in extreme environments, and long service life

4. Economic convenience: Lightweight, easy to lay, labor-saving, low material cost, and compatible with multiple engineering processes

Products Introduction:

Geo Fabric Material is a type of functional geosynthetic material made from high molecular weight polymers such as polypropylene (PP) and polyester (PET) through processes such as weaving, needle punching, non-woven, and thermal bonding. It is the "foundation protection and reinforcement core" in the field of civil engineering. Its core value lies in the flexible combination of the five basic functions of "isolation, filtration, reinforcement, drainage, and protection" to solve common problems such as unstable soil structure, mixed engineering materials, and water retention, providing lightweight and low-cost structural optimization solutions for various projects.

Product Features:

1. Multi functional integration, adapted to common engineering requirements

It has five core functions: isolation, filtration, reinforcement, drainage, and protection. The isolation function can separate soil and building materials of different grades to prevent mixing between layers; The filtering function intercepts fine particles to ensure smooth drainage; Strengthening function enhances the bearing capacity of soil; Drainage function to divert moisture and prevent water accumulation; The protective function reduces the wear and impact of external forces on the structure. Different types of geotextiles can focus on a specific function or collaborate with multiple functions to meet the diverse needs of engineering.

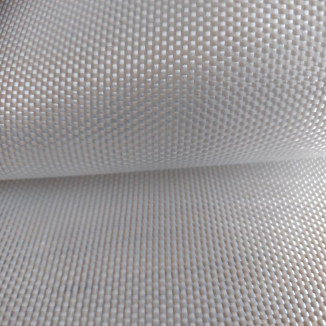

2. Adjustable mechanical properties, suitable for different stress scenarios

By selecting raw materials and adjusting processes, the mechanical properties are flexible and controllable: the longitudinal and transverse fracture strength of woven geotextiles can reach 15-150kN/m, suitable for heavy-duty reinforcement scenarios; The fracture elongation rate of non-woven geotextile is 20% -50%, suitable for flexible bonding requirements. At the same time, it has excellent tear resistance and puncture resistance, and can resist external forces such as construction machinery rolling and soil friction, ensuring the stability of the engineering structure.

3. Weather resistant, corrosion-resistant and durable, with a wide range of environmental adaptability

The raw materials have undergone anti UV, anti acid and alkali, and anti microbial degradation treatment, and can be stably used in the extreme temperature range of -40 ℃ to 90 ℃. They are resistant to saline alkali soil, groundwater immersion, outdoor sun and rain exposure, and industrial environment erosion. The buried service life can reach 5-25 years, and the exposed service life can reach 3-10 years, significantly reducing the frequency and cost of maintenance in the later stage of the project.

4. Flexible and easy to lay, compatible with complex working conditions and processes

The texture is soft and has good extensibility, which can naturally fit irregular terrains such as undulating surfaces, curved slopes, narrow ditches, etc., without blind spots for laying; Lightweight and easy to cut, the length of a single roll can reach 50-200m, and only manual labor or small machinery is needed to complete the laying, with a construction efficiency of 500-1000 square meters per day. Simultaneously compatible with subsequent processes such as asphalt paving, concrete pouring, and crushed stone compaction, without the need to adjust the engineering process.

5. Economic and environmental protection, optimizing the full cycle cost of engineering

The material cost is only 1/5-1/2 of traditional rigid materials such as concrete and steel plates, and the construction does not require large equipment, reducing labor costs by more than 30%; In long-term use, due to the improvement of structural stability, the maintenance cycle of the project is extended by 2-5 times, and the overall cost advantage is significant. In addition, polymer raw materials can be recycled, and some products are made of recycled materials, which is in line with the concept of green engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation infrastructure engineering

Highway/railway subgrade: Woven geotextile is laid between the soft soil layer and the sand and gravel cushion layer of the subgrade, reinforced to enhance the bearing capacity and prevent settlement and deformation; Non woven geotextile is used for roadbed drainage layer, filtering fine soil to ensure smooth drainage, suitable for highways, rural roads, heavy-duty railways and other projects.

Road surface and runway: Lay geotextile between asphalt/concrete surface layer and base layer to reduce reflection cracks, enhance interlayer adhesion, and adapt to scenarios such as municipal road renovation and airport runway maintenance.

2. Water conservancy and slope protection engineering

River/reservoir embankment: Non woven geotextile is used for anti filter drainage of embankment slopes to prevent soil loss and pipe surge; Machine woven geotextile reinforced dam body enhances anti sliding stability and is suitable for small and medium-sized dam reinforcement and river flood control projects.

Slope treatment: Geotextile is laid on the slopes of highways and mining waste dumps, and combined with spraying and greening to form a "reinforced ecological" composite protection to prevent slope collapse and soil erosion.

3. Municipal and Construction Engineering

Municipal roads/squares: laid between the roadbed and the ground base to enhance the ground's resistance to deformation, reduce ground depressions caused by underground pipeline backfilling, and adapt to the renovation of old city roads and the construction of new municipal squares.

Building foundation and basement: Non woven geotextile is used for foundation drainage and moisture prevention, while woven geotextile is used for reinforcing weak foundations to prevent building settlement and wall cracking. It is suitable for multi story buildings and underground garage construction.

4. Landscape and Agricultural Engineering

Landscape: Non woven geotextile is used as a ground cloth to suppress weed growth, and is used in conjunction with drainage layers for roof greening and flower bed construction; Woven geotextile is used for landscape slope reinforcement and is suitable for park and community greening projects.

Agricultural water conservancy: Laying geotextiles in irrigation channels and reservoirs to prevent channel leakage and collapse, improve water resource utilization efficiency, and adapt to agricultural water conservancy renovation and water-saving irrigation projects.

5. Mining and Environmental Protection Engineering

Mine tailings pond: High strength woven geotextile is used for reinforcing the dam body and protecting the anti-seepage layer of the tailings pond to prevent landslides and pollutant leakage, and is suitable for mine safety protection projects.

Landfill site: Non woven geotextile is used as a protective layer and drainage layer for the anti-seepage membrane of the landfill site, filtering the leachate from the garbage, protecting the anti-seepage system, and adapting to the construction of environmentally friendly landfills.

Geo Fabric Material has the core advantages of "diverse functions, adjustable performance, weather resistance and durability, and economic and environmental protection", accurately solving the common pain points of "structural stability, material compatibility, moisture management, and cost control" in civil engineering. It is the "foundation protection and functional strengthening cornerstone" of various engineering constructions.