Geotex Non Woven

1. Strong integrity: forming a continuous whole with uniform force distribution.

2. Easy construction: lightweight, easy to transport and lay, can significantly shorten the construction period.

3. Good durability: Synthetic fibers are corrosion-resistant and resistant to microbial and insect infestations.

4. Easy to control quality: Industrial production ensures stable quality.

5. High economic benefits: It can usually replace traditional sand and gravel materials, saving material, transportation, and labor costs

Product Introduction:

Geotex Non Woven is a permeable geosynthetic material made of synthetic fibers through needle punching or weaving. Here is a detailed introduction about it:

Classification

Classified by production process:

Woven geotextile: warp knitted or plain weave, with regular arrangement of fibers, characterized by high strength and low elongation, suitable for container yard reinforcement, coastal protection and other projects.

Non woven geotextile: formed into a three-dimensional mesh structure through needle punching, water punching, or thermal bonding, with high porosity and strong permeability, commonly used in landfill filter layers, roadbed drainage, etc.

Composite geotextile: Combining the characteristics of spun fabric and non-woven fabric, or composite with geotextile membrane, such as fabric membrane composite geotextile, which has both anti-seepage and drainage functions, can be used for reservoir anti-seepage, tunnel reinforcement and other projects.

Classified by fiber type:

Short fiber geotextile: Low cost, good flexibility, but average tensile strength, suitable for temporary projects or projects with limited budgets.

Long fiber geotextile: Its tensile strength can reach 2-3 times that of short fiber fabric, and it has excellent corrosion resistance. It is commonly used in permanent projects such as highways and water conservancy projects.

Feature

High strength: Using plastic fibers, it can maintain sufficient strength and elongation in both dry and wet conditions.

Corrosion resistance: It can resist corrosion for a long time in soil and water with different acidity and alkalinity.

Good permeability: There are gaps between fibers, and the water permeability is good.

Good antimicrobial properties: It is not damaged by microorganisms or insects.

Convenient construction: The material is light and flexible, making transportation, laying, and construction very convenient.

Effect

Isolation: Isolate building materials with different physical properties to prevent loss or mixing between two or more materials, and maintain the overall structure and function of the materials.

Filtration: When water flows from the fine soil layer into the coarse soil layer, good air permeability and permeability are utilized to allow the water flow to pass through, effectively intercepting soil particles, etc., to maintain the stability of soil and water engineering.

Drainage: It has good water conductivity and can form drainage channels inside the soil to discharge excess liquids and gases from the soil structure.

Reinforcement: Enhance the tensile strength and deformation resistance of soil, strengthen the stability of building structures, and improve soil quality.

Protection: When water flows on soil, it effectively disperses, transmits or decomposes concentrated stress, preventing soil from being damaged by external forces and protecting the soil.

Performance Parameters

Physical properties: Common specifications for weight range from 100g/㎡ to 800g/㎡, with a thickness of 0.5mm-3.0mm; The porosity of non-woven fabric is 70% -90%, and the vertical permeability coefficient is greater than 0.1cm/s; The elongation at break of woven fabric is less than 15%, and non-woven fabric is greater than or equal to 40%.

Mechanical properties: Longitudinal breaking strength of woven fabric ≥ 80kN/m, non-woven fabric ≥ 14MPa; The tear strength of short fiber cloth is ≥ 0.08kN, the tear strength of long fiber cloth is ≥ 0.20kN, and the burst strength of composite geotextile is ≥ 1.5kN.

Durability: Polypropylene material is acid and alkali resistant, polyester material is oil resistant; After treatment with UV stabilizer, the service life is ≥ 50 years; EVA geotextile is suitable for low temperature environments of -70 ℃.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road traffic engineering

This is the most traditional and largest application area of geotextiles.

Newly built highway/railway subgrade

Function: Isolation+Reinforcement

Application scenario: When constructing embankments on soft soil foundations.

Specific method: Lay geotextile on the soft foundation surface, and then fill it with roadbed materials (such as sand and gravel).

Road maintenance and repair

Function: Protection (crack prevention)+isolation

Application scenario: Adding a new asphalt surface layer on an old asphalt pavement or old cement concrete pavement.

Specific method: Lay geotextile (usually combined with emulsified asphalt binder oil) on the old road surface, and then spread new asphalt concrete.

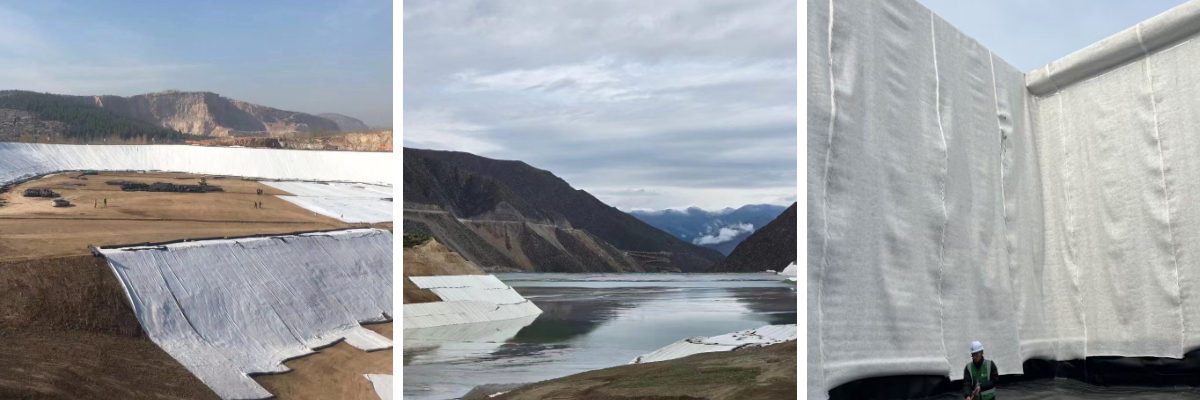

2. Water conservancy engineering

Embankment and breakwater

Function: Filtration+Protection

Application scenarios: Embankment protection structures for rivers, lakes, and coasts.

Specific method: Lay geotextile between protective materials such as stone throwing and concrete blocks and the lower soil slope.

Drainage ditch and filter layer

Function: Filtration+Drainage

Application scenarios: inside earth and rock dams, behind retaining walls, below channel linings, and other areas that require drainage.

Specific method: Wrap the geotextile around the gravel drainage blind ditch, or directly lay it between the drainage structure and the soil.

3. Environmental Geotechnical Engineering

This field has the highest requirements for material performance, usually using high-performance non-woven fabrics or composite materials.

Garbage sanitary landfill site

Function: Protection+Filtration+Drainage

Application Scenario:

Bottom protection system: laid below and above the HDPE anti-seepage membrane.

Under the membrane: mainly serves as a protective measure to prevent sharp objects in the foundation from puncturing the expensive anti-seepage membrane.

On the membrane: serving as the filter layer and water conducting layer of the leachate collection system, while protecting the impermeable membrane.

Final coverage system: In the sealed coverage layer, it plays a role in drainage and filtration.

Tailings pond, fly ash storage yard

Function: Similar to a landfill, it is used to prevent harmful liquid leakage and ensure stable drainage of the pile.

4. Construction and Municipal Engineering

Foundation drainage

Function: Drainage+Filtration

Application scenarios: Surrounding building foundations and basements.

Specific method: Lay geotextile wrapped drainage pipes or blind drainage ditches on the outside of the foundation wall to collect and divert groundwater, lower the groundwater level, and reduce the structural waterproof pressure.

Roof garden and underground garage roof drainage

Function: Filtration+Drainage

Specific method: Lay geotextile under the planting soil to prevent soil particles from blocking the drainage boards or pipes below, while ensuring the smooth discharge of excess water.

Tubing wrap

Function: Filtration+Protection

Application scenario: Surrounding municipal drainage pipes and seepage pipes.

Specific method: Wrap the gravel and pipeline with geotextile to form a complete drainage and filtration system, preventing soil from entering and blocking the pipeline.

5. Other special applications

Reinforced earth retaining wall/steep slope

Function: Reinforcing

Application scenario: Building high retaining walls or ecological slopes.

Specific method: Lay high-strength woven or knitted geotextile in layers in the fill soil, fold one end back or connect it to the panel, and use friction to pull the soil to form a stable composite structure. This structure is lighter, softer, and more cost-effective than traditional retaining walls.

Emergency engineering and temporary roads

Function: Isolation+Reinforcement

Application scenario: temporary channels need to be built quickly in soft areas such as mudflat and marshes.

Specific method: Directly lay one or more layers of high-strength geotextile as a "geogrid", and then fill a small amount of stone to quickly form a passable construction access road.

In summary, the application of geotextiles is a model of the combination of modern engineering technology and materials science. It systematically solves stability, durability, and environmental issues in engineering through a relatively simple and economical material. When selecting and applying geotextiles, it is necessary to choose the appropriate type and specification based on specific engineering requirements, soil conditions, and functional requirements.