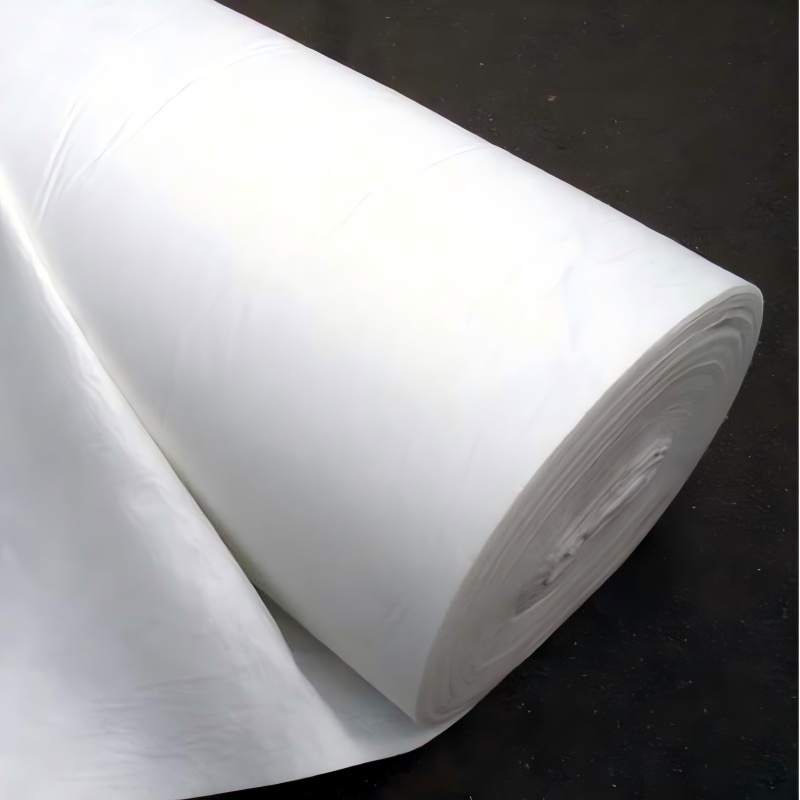

Geotextile for Slope Stabilization

1. Reinforcement and Landslide Prevention: Fibers interweave to form a stable network, enhancing the shear strength of the slope soil, distributing soil pressure, and reducing the risk of landslides caused by rainwater erosion and weight.

2. Permeable Soil Filtration and Structure Protection: Rainwater is allowed to seep out, preventing water accumulation and softening of the soil. Fine soil particles are also filtered to prevent soil erosion, which can lead to slope cavities and collapse.

3. Weather and Corrosion Resistance: Treated with UV, acid, and alkali resistance, it withstands strong outdoor sunlight and rain, making it resistant to aging and damage in locations like mountainous terrain and riverbanks.

4. Easy Laying and Adaptability: Its flexible texture conforms to irregular slope contours, making it easy to cut without complex equipment, adapting to slope reinforcement needs of varying slopes (e.g., gentle slopes and steep slopes).

Products Introduction:

Geotextile for Slope Stabilization (Geotextile for Slope Stabilization) is a functional geosynthetic material designed specifically for slope reinforcement and collapse prevention. Made from high-strength polypropylene (PP) or polyester (PET), it is produced through needle-punched nonwovens, woven fabrics, or composite processes. Some models are additionally treated for UV and acid-base corrosion resistance. Its core function is to create an integrated "reinforcement-filtration-protection" system within or on the surface of the slope soil. This system not only enhances soil shear strength and prevents slope slippage, but also channels rainwater and prevents soil erosion. This mitigates the risk of collapse on natural and engineered slopes caused by rainwater erosion, self-weight settlement, and geological changes. This product is suitable for applications such as highway slopes, mine slopes, riverbanks, and construction pit slopes. It requires no complex construction process and is a key material for improving slope stability and ensuring ecological and engineering safety.

Product Features:

1. Strong reinforcement, anti-slip and anti-collapse: Utilizing a filament interwoven or high-density needle-punching process, the fabric achieves longitudinal and transverse tensile strengths of 20-80 kN/m and excellent tear resistance. After installation, it tightly bonds with the slope soil, forming a "soil-fabric composite structure" that significantly enhances soil shear strength and distributes stresses generated by the slope's own weight and external loads (such as rainwater infiltration), effectively resisting slope slip and collapse. It is particularly suitable for slopes with steep slopes (30°-60°) or soft soil foundations.

2. Water-permeable soil filtration, soil protection and drainage: The fabric's scientifically designed pore size (non-woven models have a pore size of 0.05-0.5mm, while woven models have a uniform and controllable pore size) allows it to quickly drain rainwater and groundwater from the slope, preventing water accumulation from softening the soil and increasing slope weight. It also filters fine particles (clay and silt) in the soil, preventing them from escaping with water and forming cavities within the slope, thus maintaining the integrity of the slope's soil structure over the long term.

3. Weather-Resistant and Corrosion-Resistant, Long-Lasting Durability: The base fabric is made of an ageing-resistant polymer material and treated with UV-resistant, acid- and alkali-resistant coatings. It withstands harsh outdoor environments such as strong sunlight, rain, and soil corrosion (e.g., acidic soil and saline-alkali land). It maintains stable performance within a temperature range of -30°C to 80°C. Under normal operating conditions, it boasts a service life of 10-20 years, ensuring long-term slope stability and reducing maintenance requirements.

4. Flexible Adaptability, Easy and Efficient Laying: Its flexible texture and lightweight (unit weight of 100-400g/m²) allow it to be flexibly cut and spliced to suit slope contours (e.g., curved and stepped slopes) without the need for specialized heavy equipment. During laying, it adheres closely to the slope surface or embeds itself into the soil layer structure, eliminating wrinkles and hollows. It is adaptable to various slope types and construction environments. Compared to traditional stone masonry and shotcrete reinforcement, it shortens the construction period by over 30%, reducing labor costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Highway and Railway Slope Reinforcement: This geotextile is applied to fill or cut slopes along highways and railways, particularly in mountainous areas. Its reinforcement prevents slippage caused by vehicle vibration and rainwater erosion. Its drainage and soil filtration functions prevent soil loss and collapse, which could impact traffic safety. In some locations, it can be combined with grass planting to achieve the dual benefits of "reinforcement and ecological restoration."

2. Mining and Quarry Slope Management: High and steep slopes (often exceeding 60°) formed after mining operations are prone to landslides due to rock fragmentation and rainwater infiltration. Applying this geotextile strengthens the integrity of the loose soil and prevents rock erosion. It also directs water accumulation within the slope, reducing rainwater erosion and providing a stable foundation for mine ecological restoration (such as spraying).

3. River and Reservoir Slope Protection: This geotextile is used in river and reservoir bank management and is applied to the slope surface or within the layered structure. On the one hand, it prevents soil loss caused by water erosion and protects the bank slope shape. On the other hand, its drainage function reduces the moisture content of the bank slope soil, preventing collapse due to increased deadweight and reduced strength, thereby ensuring the safety of river flow and reservoir water storage.

4. Construction pit and municipal slope protection: This geotextile can be laid as a temporary reinforcement layer on temporary slopes formed by construction pit excavation and on slopes of municipal projects (such as underground pipeline corridor construction) to mitigate the risk of short-term slope slippage. It also prevents soil collapse caused by rainwater erosion of the foundation pit slope, creating a safe environment for subsequent construction. After construction is completed, it can be recycled or integrated into permanent structures as needed.

Geotextile for Slope Stabilization leverages its core advantages of "reinforced anti-slip properties," drainage and soil filtration, weather resistance, durability, and adaptability for easy construction. It precisely addresses the pain points of various slope projects, including difficulty stabilizing, erosion, and expensive maintenance. Whether for long-term slope protection along transportation routes, ecological slope management in mining and water conservancy projects, or temporary slope reinforcement in construction projects, its scientifically designed performance creates a reliable protective barrier for slopes, enhancing structural stability while minimizing ecological disruption. As the "invisible support" of slope stabilization projects, this product balances functionality and affordability, providing efficient solutions for slope safety in diverse scenarios without requiring complex technology or high investment. It is an ideal material for promoting "safe, ecological, and cost-effective" slope engineering.