Geo Fabric Under Gravel

1. Isolation and anti mixing, keeping the gravel loose: Accurately separate the gravel from the underlying soil, prevent fine soil from surging up and blocking the gravel gaps, maintain the loose structure of the gravel layer for a long time, and ensure the load-bearing and drainage foundation.

2. Efficient drainage and anti softening of the base layer: Fiber pores allow rainwater to quickly penetrate, while filtering sediment to avoid channel blockage, reducing the softening and settlement problems of the base layer caused by accumulated water in the gravel layer.

3. Flexible reinforcement, anti deformation and cracking: The interwoven fiber network disperses the load, enhances the overall anti deformation ability of the gravel layer and the base layer, and reduces the indentation and cracking caused by vehicle rolling or heavy pressure.

4. Grass blocking and maintenance reduction, cost reduction: Physically blocking the penetration of miscellaneous grass roots through gravel layers, eliminating the need for frequent weeding, and reducing the maintenance workload and cost of gravel areas such as courtyard paths and parking lots.

Products Introduction:

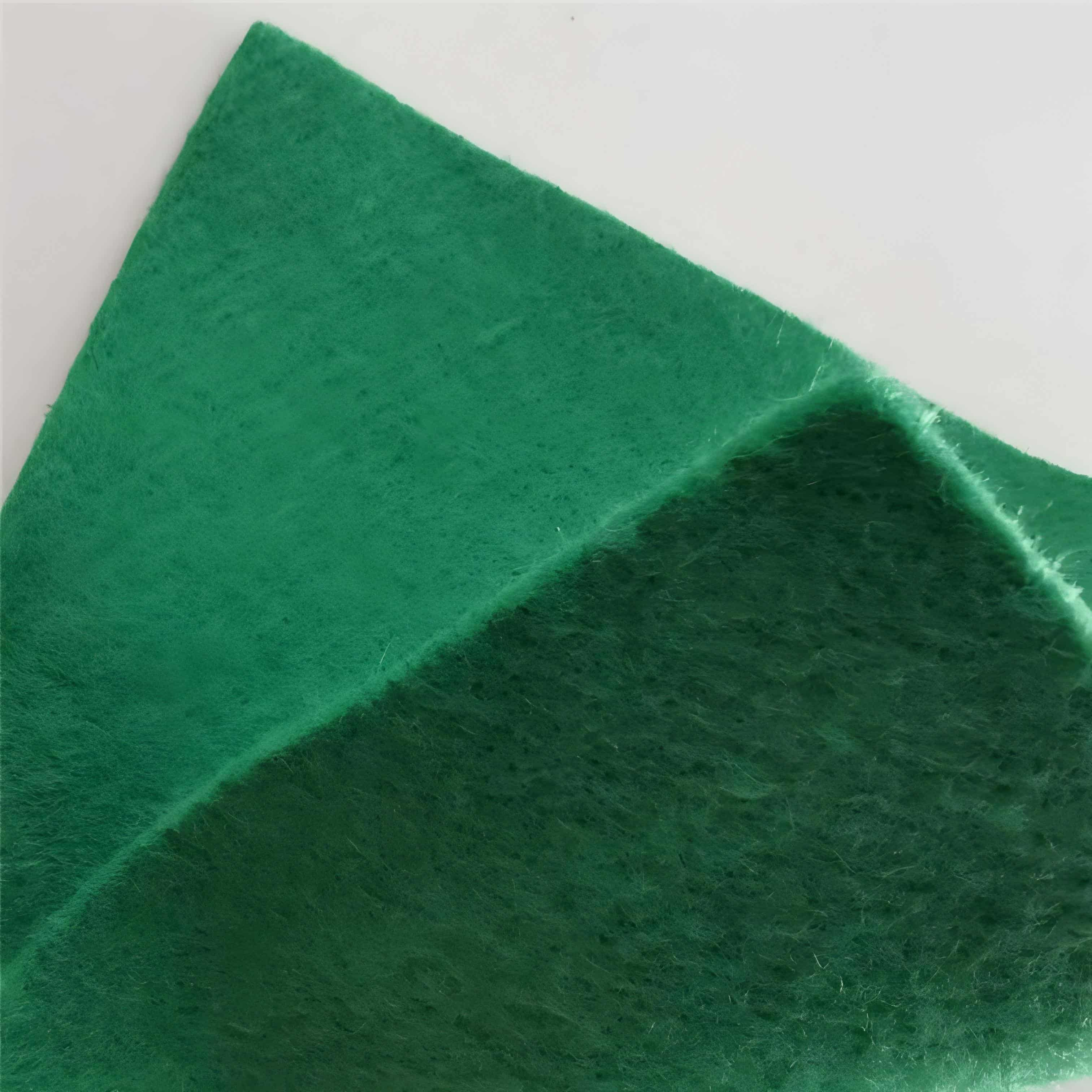

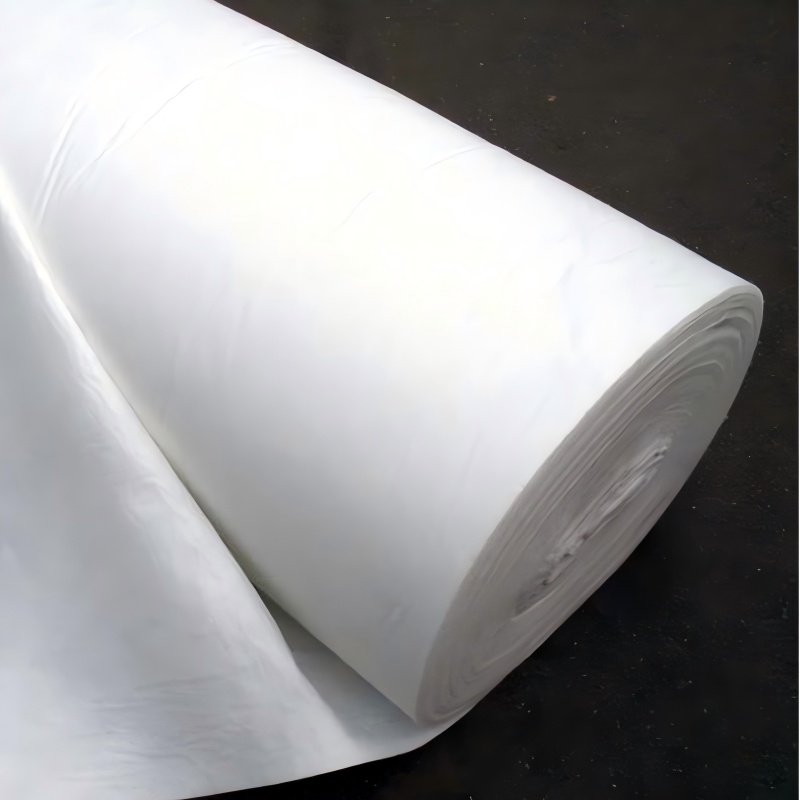

Geo Fabric Under Gravel is a geosynthetic material designed specifically for gravel laying scenarios. It is made from polypropylene (PP) or polyester (PET) and is produced through needle punching (non-woven) or weaving processes. It is mainly laid between the gravel layer and the underlying soil. Its core function is to solve the four major pain points of "soil and gravel mixing, drainage blockage, base settlement, and weed growth" in gravel engineering, providing stable base support for scenes such as courtyard paths, parking lots, roadbed cushions, and landscape gravel areas. It can maintain the integrity of the gravel layer structure and extend the overall service life of the project. It is an indispensable supporting material for gravel laying.

Product Features:

1. Precise isolation and prevention of interlayer mixing: The fabric pores have been optimized in design (non-woven pore size 0.05-0.5mm, woven pore size uniformly controllable), which can accurately block the upwelling of fine particles (clay, silt) in the soil, avoiding them from filling the gaps between crushed stones and causing the crushed stone layer to solidify. At the same time, it prevents crushed stones from being embedded in the soft soil below, maintaining the loose structure of the crushed stone layer for a long time and ensuring its load-bearing and drainage functions.

2. Efficient drainage, anti water accumulation and softening: With excellent permeability, rainwater or surface water can quickly penetrate into the ground through geotextiles, while filtering sediment to prevent blockage of drainage channels; Compared to laying without geotextile, the drainage efficiency of the gravel layer is improved by more than 40%, reducing the softening and settlement problems of the base soil caused by water accumulation.

3. Flexible reinforcement and resistance to deformation and cracking: The non-woven type relies on a three-dimensional network formed by interwoven fibers, while the woven type relies on a long filament weaving structure, both of which have good tensile strength (10-50kN/m) and tear resistance. They can disperse the pedestrian and vehicle loads borne by the gravel layer, evenly transmit stress to the soil, reduce the depression and cracking of the gravel layer caused by long-term heavy pressure, and enhance the overall structural stability.

4. Grass blocking and weather resistance, reducing maintenance costs: Physically blocking the penetration of miscellaneous grass roots through gravel layers to prevent weeds from growing through cracks in the gravel, without the need for frequent manual weeding or herbicide spraying; At the same time, after anti ultraviolet and anti-aging treatment, outdoor exposure can withstand direct sunlight and rain immersion, with a service life of 5-15 years, greatly reducing the later maintenance costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Courtyard and Landscape Gravel Area: The gravel paths in the courtyard and the gravel cushion layer in the garden landscape are laid below to block the mixing of fine soil particles and gravel, preventing the path from being compacted and affecting the walking experience; Simultaneously inhibiting weed growth, maintaining landscape cleanliness, and reducing yard maintenance workload.

2. Parking lots and private lanes: In gravel paved family parking lots and rural lane bases, as an isolation reinforcement layer, it disperses vehicle crushing loads, reduces gravel indentation and displacement; Efficient drainage function prevents rainwater from accumulating in the lane, preventing vehicle slippage or softening of the base layer.

3. Roadbed and road cushion layer: Lay under the gravel roadbed of rural roads and scenic roads, isolate the roadbed soil and gravel, and prevent soil disturbance from causing roadbed deformation; Enhance the overall anti settlement ability of the roadbed, and cooperate with the drainage function to ensure the stability of road traffic during the rainy season.

4. Slope and drainage engineering: The gravel protective layer is laid below the mountain slope to prevent soil erosion and accelerate rainwater infiltration, reducing the erosion of the slope caused by rainwater erosion; Used in the gravel filtration layer of drainage ditches and seepage wells to filter sediment and prevent blockages in the drainage system

Geo Fabric Under Gravel accurately solves the core pain points of gravel laying scenarios with its four core advantages of "isolation and anti mixing, efficient drainage, flexible reinforcement, and grass resistance and weather resistance". It can not only maintain the structural and functional stability of the gravel layer, extend the service life of the project, but also adapt to various scenarios such as courtyards, parking lots, roadbeds, slopes, etc., balancing practicality and economy. Whether it is small-scale home landscape renovation, or small and medium-sized road and slope engineering, their "low-cost investment, high-value return" characteristics can provide reliable guarantees for the project, and are key supporting materials for improving efficiency and reducing maintenance costs in gravel paving engineering.