Beda Geotextile Woven Dan Non Woven

1. Strong classification adaptability: covering both woven and non-woven types, woven styles are strong, durable, and adaptable to heavy-duty scenarios, while non-woven styles are permeable, soft, and adaptable to filtering and buffering needs, meeting different engineering segmentation scenarios.

2. Complementary and comprehensive performance: Woven fabrics have outstanding tensile and tear resistance, while non-woven fabrics have excellent filtration and drainage effects.

3. Durability and environmental compatibility: Both types are made of weather resistant materials, which are resistant to ultraviolet radiation, acid and alkali corrosion.

4. Flexible and cost-effective construction: Woven fabric can be spliced to adapt to large-scale laying, while non-woven fabric is lightweight and easy to cut and paste in irregular areas.

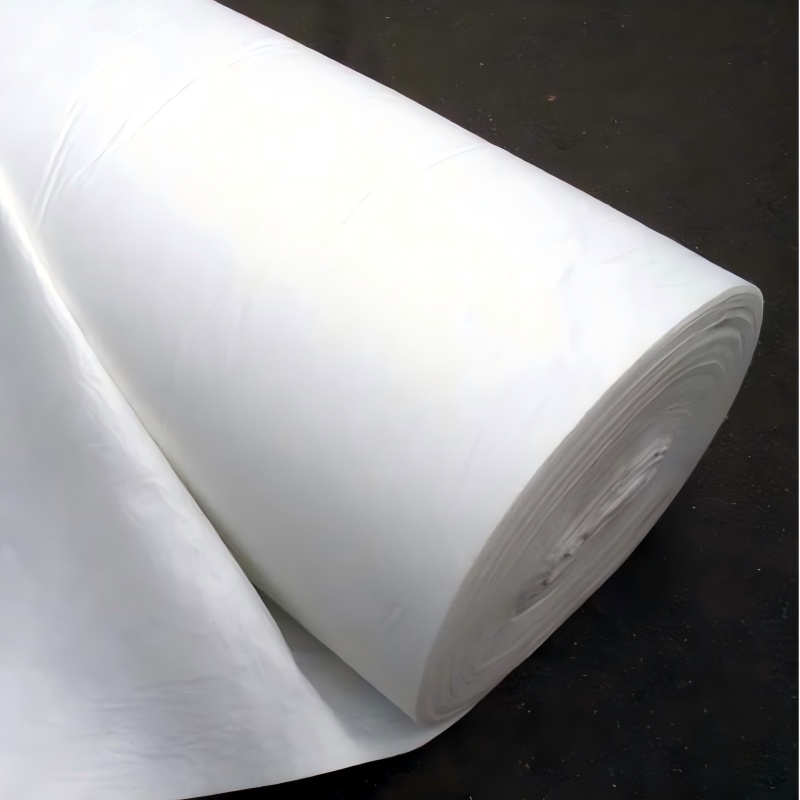

Products Introduction:

Beda Geotextile Woven Dan Non Woven is a general term for two core products in geosynthetic materials, representing Woven Geotextile and Non Woven Geotextile respectively. Both use high molecular weight polymers (such as polypropylene and polyester fibers) as raw materials, but their processing techniques are completely different: woven geotextiles are woven by interweaving warp and weft yarns, with a tight structure and outstanding strength; Non woven geotextiles are formed by randomly arranging and bonding fibers through processes such as needle punching, hot melting, or spunbonding, creating a fluffy and porous structure. As widely used basic materials in engineering construction, woven and non-woven geotextiles have their own functions, but they jointly cover core requirements such as soil reinforcement, filtration and drainage, and isolation protection, providing targeted solutions for different engineering scenarios.

Product Features:

Woven Geotextile

1. High strength mechanical properties: The interwoven structure of warp and weft yarns endows it with extremely high tensile strength and tear resistance, with a fracture strength of up to 20-300kN/m. It can withstand the long-term effects of heavy loads (such as vehicle and dam water pressure), effectively transmit stress in structural reinforcement, and suppress soil displacement.

2. Excellent dimensional stability: The weaving process makes its structure compact, with a low longitudinal and latitudinal shrinkage rate (usually less than 3%), and is not easily deformed in long-term stress or temperature changing environments. It can maintain a stable physical form and ensure the dimensional accuracy of engineering structures.

3. Strong wear and corrosion resistance: The surface is smooth and the fiber density is high, with outstanding friction resistance, which can resist mechanical rolling and sharp object scratching during the construction process; At the same time, it has good chemical stability, acid and alkali resistance, anti-aging, and is suitable for special environments such as saline alkali land and industrial pollution areas.

Non Woven Geotextile

1. Efficient filtration and drainage function: The porous structure formed by random arrangement of fibers (porosity can reach 70% -90%) can accurately block soil fine particles (effective particle size below 0.075mm), prevent mixed pollution of different soil layers, and quickly discharge water. The permeability can reach 10-100m/d, avoiding water accumulation in the engineering area.

2. Good flexibility and adhesion: The texture is soft and has strong extensibility, which can tightly adhere to irregular terrain (such as slopes and curved foundations), without wrinkles or hollows, and can fully contact the soil, evenly distribute loads, and reduce local stress concentration.

3. Excellent ecological compatibility: The porous structure provides space for microbial growth and plant root growth, and can be combined with ecological restoration projects (such as vegetation slope protection and wetland construction) without affecting soil permeability and biological activity, in line with the concept of green engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

Application scenarios of woven geotextile

1. Heavy civil engineering: used as a roadbed reinforcement layer for highways and railways, to withstand vehicle loads and suppress roadbed settlement; As a reinforcing material in structures such as dams and retaining walls, it enhances the shear strength of the walls and prevents collapse.

2. Mining and Energy Engineering: Installed on the dam body of the mine tailings pond to resist the lateral pressure generated by tailings accumulation; As a protective layer in the laying of oil and gas pipelines, it protects the pipelines from soil compression and sharp stone damage.

3. Port and water conservancy engineering: used for reinforcing the foundation of breakwaters and docks to resist wave impact and water flow erosion; Used as embankment reinforcement material in river regulation to prevent bank slope collapse.

Application scenarios of non-woven geotextiles

1. Drainage and filtration engineering: serving as a filtering layer in underground drainage systems (such as blind ditches and infiltration ditches) to prevent sediment from entering drainage pipes and causing blockages; Quickly drain accumulated water in the drainage layer of the rooftop garden and underground garage roof to protect the building structure.

2. In the field of agriculture and horticulture: used for slope protection of irrigation channels in farmland, filtering water flow and reducing soil erosion; As an isolation layer in the greenhouse foundation to prevent soil from mixing with the sand and gravel cushion layer.

3. Environmental Protection and Municipal Engineering: As an auxiliary filtration layer for the anti-seepage system in landfills, it prevents soil pollution caused by leachate from garbage; As an isolation layer in the grassroots of urban roads, it separates sand and gravel materials of different grades.

Beda Geotextile Woven Dan Non Woven (woven and non-woven geotextiles), with its differentiated structure and properties, together form the core system of geosynthetic materials. Woven geotextiles are known for their high strength and stability, making them suitable for heavy engineering projects that require structural reinforcement and load-bearing capacity; Non woven geotextiles have the advantages of efficient filtration and flexible bonding, and are widely used in drainage, isolation, and ecological engineering. The two can be used separately to meet specific needs, or combined for application (such as a composite system of "woven reinforcement+non-woven filtration"), forming complementary functions and comprehensively improving engineering quality. Whether it is heavy infrastructure, water conservancy and transportation, ecological protection, agriculture and horticulture, woven and non-woven geotextiles can provide economical and reliable solutions by accurately matching scene requirements, which is an important material support for achieving efficient protection and green sustainable development in modern engineering construction.