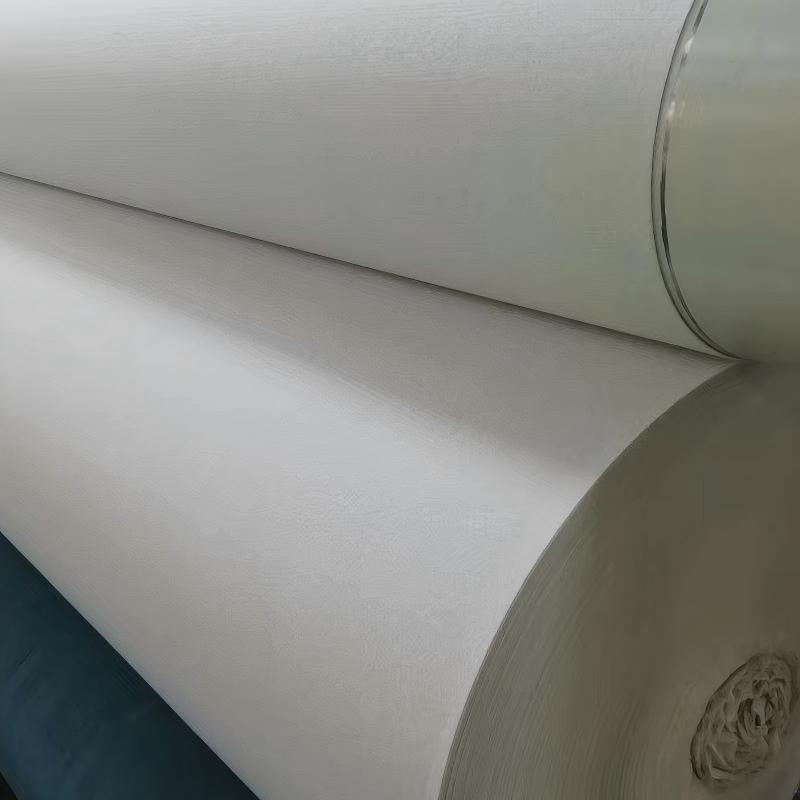

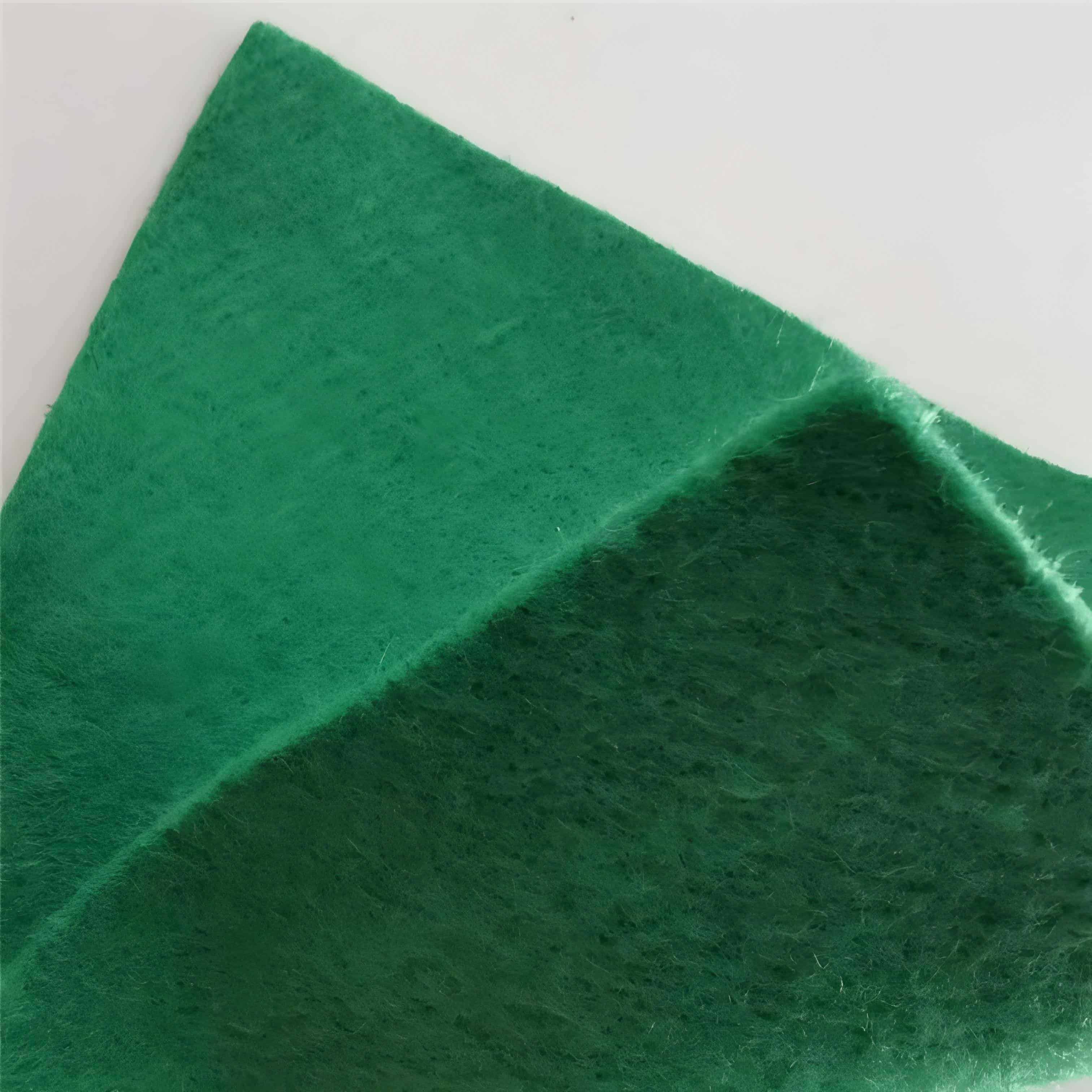

Geotextile Cloth

1.High-Efficiency Filtration & Drainage

Permeable to water but impervious to soil, effectively separating soil layers while facilitating drainage and preventing clogging.

Reduces underground hydrostatic pressure, enhancing foundation stability.

2.Reinforcement & Protection

High tensile strength distributes loads, improving load-bearing capacity of soft foundations, slopes and other structures.

Prevents soil erosion and resists weathering/scouring.

3.Separation & Impermeability

Isolates materials of different particle sizes to prevent intermixing and loss.

4.Easy & Cost-Effective Installation

Lightweight roll material enables simple manual installation, reducing equipment costs.

Product Introduction:

Geotextile Cloth is a permeable geosynthetic material made from synthetic fibers (such as polyester PET or polypropylene PP) through needle-punching, weaving, or thermal bonding processes. Widely used in civil engineering, environmental engineering, and infrastructure construction, it provides functions including reinforcement, separation, filtration, drainage, and protection.

Main Characteristics

1.Physical Properties: Tensile strength, tear strength, burst strength, etc.

2.Hydraulic Properties: Permeability coefficient, porosity (affects drainage and filtration efficiency).

3.Durability: UV resistance, chemical resistance (to acids/alkalis), aging resistance (depends on raw materials and additives).

4.Elongation: Ability to accommodate ground deformation.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1.Transportation Engineering:

Road/railway subgrade separation and drainage

2.Water Conservancy Projects:

Riverbank protection, drainage blind ditches

3.Environmental Engineering:

Landfill filter layers, tailings pond anti-seepage

4.Municipal Engineering:

Underground pipeline protection, green roof drainage

5.Agricultural Horticulture:

Soil moisture retention, weed prevention

With its multifunctionality, cost-effectiveness, and engineering adaptability, geotextiles have become an indispensable material in modern geotechnical engineering. Proper material selection and construction techniques can significantly enhance project quality and durability.