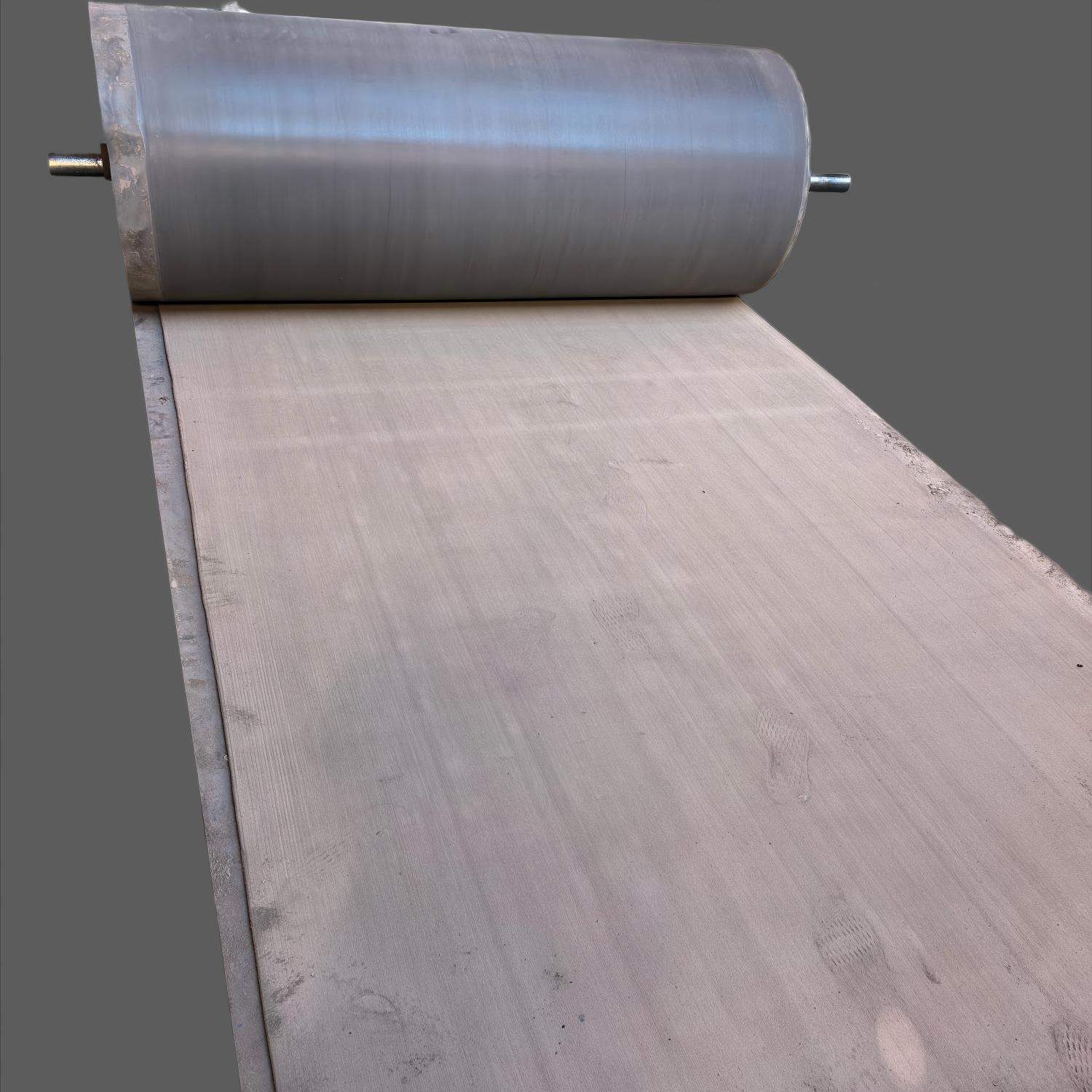

8mm Concrete Ditch Lining

1.Extremely fast construction: watering for 24 hours to harden, with an efficiency over 80% higher than traditional concrete.

2.Labor saving: It can be laid by a single person without the need for templates, mixing, or heavy machinery.

3.Flexible and durable: It can be cut and bent to adapt to complex shapes such as slopes and pipelines, with a strength of C20-C30.

4.Low cost: Save material, transportation, and maintenance costs, reducing overall costs by 30% -50%.

Product Introduction:

8mm Concrete Cloth is an innovative flexible composite material that combines the strength of traditional cement with the flexibility of textiles. It is composed of a three-dimensional fiber matrix (usually polyethylene or polypropylene) and a specially formulated dry mix concrete, which quickly hydrates and solidifies upon contact with water, forming a strong and durable concrete layer.

Core Features

1.Easy to use: It can be provided in bulk or in rolls, making it convenient for manual loading, unloading, and transportation without the need for large lifting machinery. Concrete is prepared according to scientific proportions and does not require on-site preparation. It can solidify and form underwater or in seawater.

2.Rapid solidification molding: After hydration reaction occurs during watering, its size and shape can be processed within 2 hours, and it can harden to 80% strength within 24 hours. Special formulas can also be used to achieve rapid solidification or delayed solidification according to special requirements.

3.Environmentally friendly: It is a low-quality and low-carbon technology that uses 95% less materials than commonly used concrete in many applications. The alkali content is limited, the erosion rate is very low, and the impact on the local ecology is minimal.

4.Flexible application: It has good drape and can conform to the complex shape of the covered object surface, even forming a hyperbolic shape. Before solidification, it can be freely cut or trimmed with ordinary hand tools.

5.High material strength: Fibers play a role in enhancing material strength, preventing cracking, and absorbing impact energy to form failure modes.

6.Long term durability: It has good chemical resistance, resistance to wind and rain erosion, and will not undergo UV degradation even in sunlight.

7.Good waterproof performance: The bottom has a waterproof layer, making it completely waterproof and enhancing the material's chemical resistance.

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Product Applications:

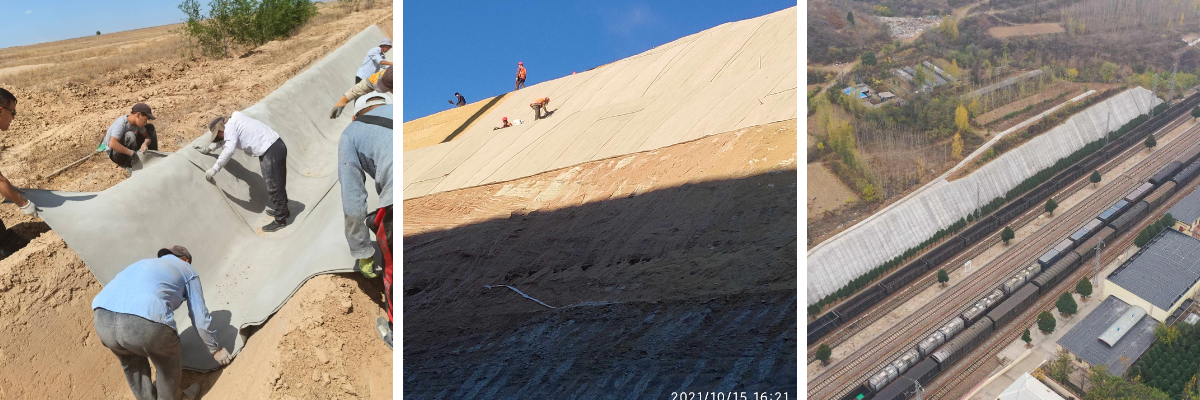

1.Transportation engineering: can be used for roadbed and road cut slope protection, quickly laid on the surface of slope protection, to prevent natural disasters such as mudslides, and protect slope protection from natural erosion; It can also be used for hardening projects on highways, railways, etc., to improve the bearing capacity and stability of road surfaces.

2.Water conservancy engineering: In water conservancy facilities such as rivers, scenic lakes, and canals, it can be used for bottom reinforcement and waterproofing treatment, as well as for dam waterproofing and seepage prevention, effectively preventing water leakage and improving the overall structural stability.

3.In the field of agriculture: suitable for aquaculture and animal husbandry, such as laying fish ponds to prevent water leakage and ensure smooth breeding; It can also be used for the construction and maintenance of agricultural irrigation channels.

4.Environmental engineering: can be applied to windbreak and sand fixation projects, fixing sand dunes and preventing the spread of desertification; In landfill sites, it can serve as an impermeable layer to prevent soil and groundwater pollution caused by leachate from garbage; It can also be used for anti-seepage in sewage treatment plants.

5.Emergency rescue: In emergency projects such as flood control embankments and temporary roads, the rapid construction characteristics enable them to be quickly laid into a solid surface, providing strong support for rescue work.

6.In the field of architecture, it can be used for roof waterproofing and basement moisture prevention in buildings; It can also be used for building repair and reinforcement, filling cracks, strengthening wall structures, etc.

Cement blankets, with their revolutionary design of "lay and use", have become an efficient solution in the engineering field, especially suitable for emergency repairs and complex terrain construction.