Non Woven Geotextile Fabric

1.Good mechanical properties:High tensile and tear resistance, can enhance foundation stability, and can adapt to slight deformation of soil.

2.Diverse functions:It can be used for anti-seepage isolation, drainage filtration, and reinforcement, and is suitable for various engineering scenarios.

3.Convenient construction:Lightweight (100-600g/㎡), can be rolled and transported, easy to cut and splice, and laid quickly.

4.Cost economy:Moderate unit price, reduces the use of traditional materials, is resistant to aging, and has low maintenance costs.

5.Environmentally friendly and durable:Made from recyclable materials, with low production pollution and a lifespan of 10-50 years, it is environmentally friendly.

Product Introduction

1.Basic attributes

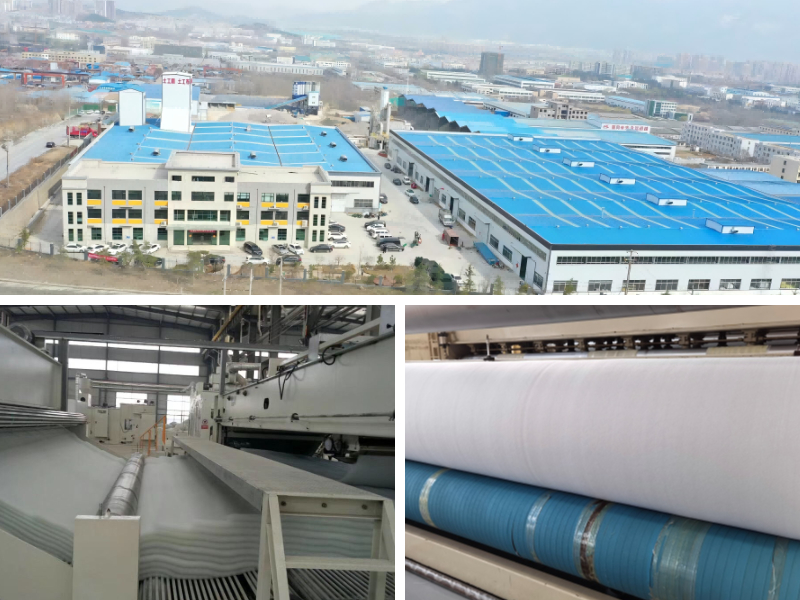

Non Woven Geotextile Fabric is a permeable geosynthetic material made from polymer materials such as polypropylene and polyester through weaving, needle punching, or bonding processes. Its appearance is mostly in the form of cloth, with a weight usually ranging from 100-600g/㎡. It has a certain degree of flexibility and tensile strength, and can be cut into different sizes according to needs for easy transportation and construction.

2.Core functions

Isolation: Separate soil, sand, and other materials of different particle sizes to prevent mixing and maintain structural stability, such as isolating soil and sand in roadbed construction.

Filtering: Allows water to pass through while blocking soil particles, avoiding soil particle loss with water, commonly used in drainage systems to prevent clogging.

Drainage: Relying on its own porous structure, excess water in the soil is drained, reducing soil saturation and enhancing foundation bearing capacity.

Reinforcement: Utilizing its high strength to enhance the tensile and shear resistance of soil, and improve the stability of structures such as foundations and slopes.

Anti seepage: Some geotextiles can effectively prevent water infiltration through special treatment and are used in anti-seepage projects such as dams and reservoirs.

3.Main features

Excellent mechanical properties: High tensile and tear resistance, able to adapt to slight deformation of soil, ensuring the stability of engineering structures.

Convenient construction: Light weight, good flexibility, can be rolled, cut and spliced, and the laying process is simple and fast, which can improve construction efficiency.

Strong durability: Resistant to corrosion and aging, able to maintain good performance in different soil and climate environments, with a service life of up to 10-50 years.

Good economy: The unit price is moderate, which can reduce the use of traditional materials, and the maintenance cost is low, making it cost-effective for long-term use.

Good environmental friendliness: Made from recyclable materials, the production process has minimal pollution and meets the requirements of green engineering.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

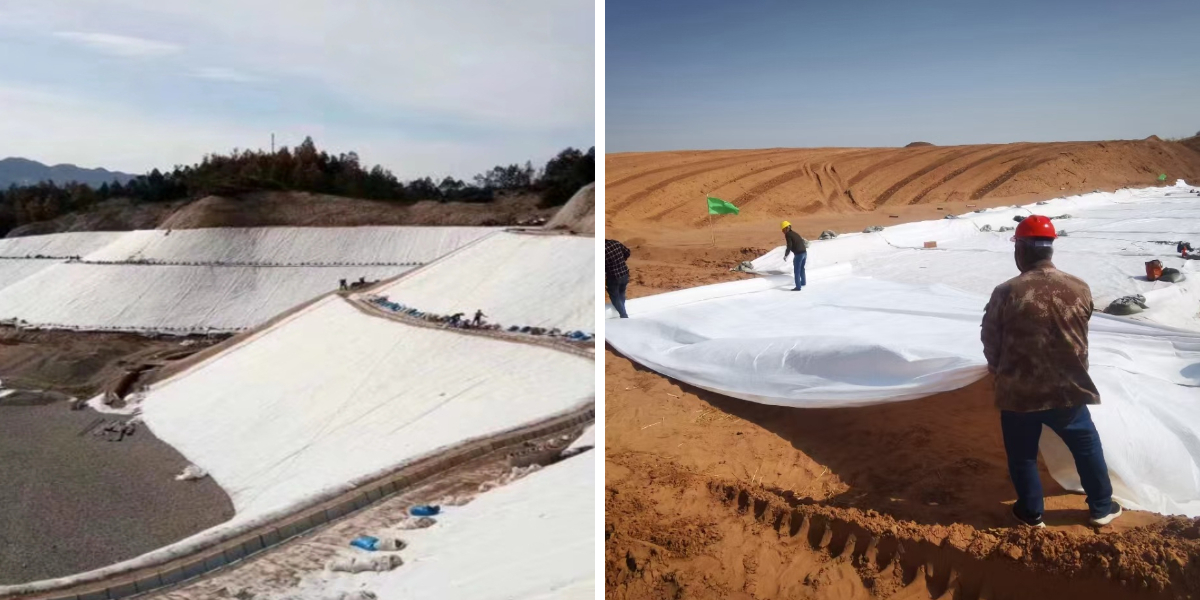

1.Application in Water Conservancy Engineering

In dam construction, geotextile can play a role in isolation and anti-seepage, separating soil materials at different levels of the dam, preventing seepage water from carrying away soil particles, and enhancing the stability of the dam; In river regulation, laying on riverbank slopes can provide reinforcement and protection, reducing slope collapse caused by water flow erosion; At the same time, laying at the bottom and surrounding areas of reservoirs and reservoirs can effectively filter water bodies, prevent blockages, and ensure the normal operation of water conservancy facilities.

2.Application in Transportation Engineering

Geotextiles are commonly used for roadbed treatment in highway and railway construction. It can isolate the roadbed soil from the sand and gravel cushion layer, avoiding their mixing and affecting the structural strength. At the same time, it can discharge the accumulated water in the roadbed through drainage function, reducing the risk of settlement; Laying between the base and surface layers of the road can reduce the wear and tear of the base caused by vehicle loads and extend the service life of the road surface; In addition, using it at the bridgehead of a bridge can alleviate the problem of vehicle jumping at the bridgehead, improve driving safety and comfort.

3.Application in Municipal and Environmental Engineering

In the municipal drainage system, geotextile is wrapped around the drainage pipes to filter impurities in rainwater or sewage, prevent pipe blockage, and ensure smooth drainage; During the construction of a landfill site, geotextile serves as an auxiliary material for the anti-seepage layer, which can enhance the anti-seepage effect and prevent leachate from polluting the soil and groundwater; In artificial lakes, landscape rivers and other projects, laying geotextiles can play a role in isolation and protection, maintaining clear water bodies and protecting the surrounding ecological environment.

Geotextiles have a wide range of important applications in various engineering fields such as water conservancy, transportation, municipal engineering, and environmental protection due to their multifunctional characteristics of isolation, filtration, drainage, reinforcement, and anti-seepage. It can not only improve the stability and durability of engineering structures, reduce construction difficulty and maintenance costs, but also assist in green engineering construction. It plays an irreplaceable role in ensuring engineering quality and ecological protection, and is an indispensable key material in modern engineering construction.