Homemade Concrete Ditch Lining

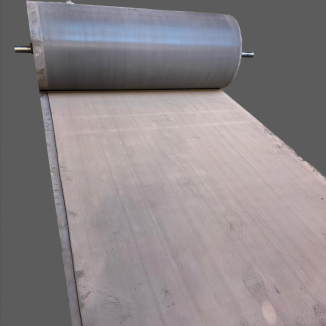

1.Convenient transportation: It can be rolled up for handling, saving a lot of transportation space and reducing transportation costs.

2.Efficient construction: No complex material ratio is required, only watering is needed to solidify and form, which can greatly shorten the construction period.

3.Strong impermeability: After curing, it can effectively prevent water infiltration and is suitable for projects such as water conservancy that require waterproofing.

4.Good durability: It can resist erosion from various natural environments and help extend the service life of the project.

5.Good environmental friendliness: Can reduce material waste and comply with environmental protection concepts.

Product Introduction

Homemade Concrete Ditch Lining is a new type of building material that combines cement with textile fibers, also known as Concrete Blankets, which combines the flexibility of textiles with the strength of concrete.

It uses specially made fiber cloth as the carrier, uniformly impregnated with dry cement powder and additives inside, in the form of a roll, making transportation and laying convenient. Simply water or soak it during use, and it can harden and form within 24 hours, making construction efficient. Before hardening, it can be bent and cut to adapt to complex terrain; After hardening, the strength is close to that of ordinary concrete, and the crack resistance and durability are good.

Widely used in small water conservancy facilities (canal, reservoir lining), slope protection, emergency engineering (road repair, riverbank reinforcement), agricultural irrigation channels and other scenarios, it can greatly simplify the construction process and reduce costs.

Product Parameters

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

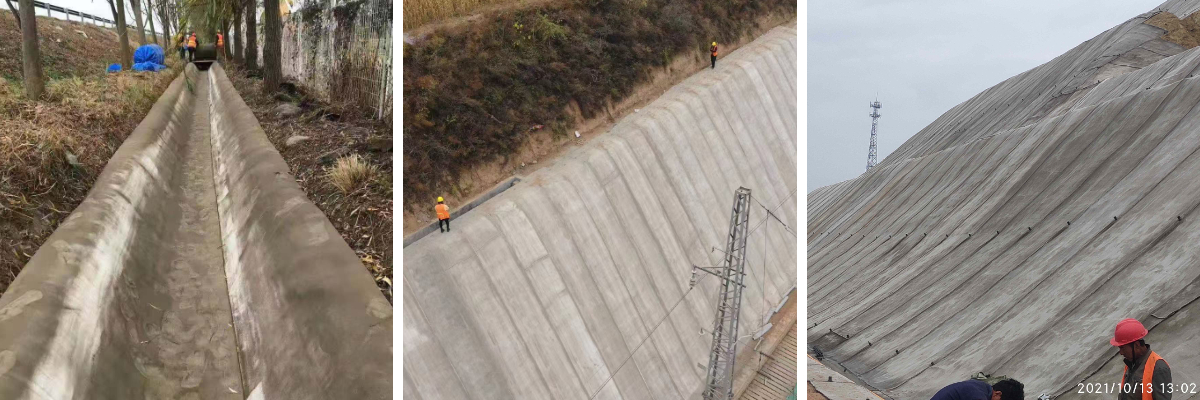

Product Application

Cement blankets have demonstrated unique value in multiple fields, combining the flexibility of textiles with the strength of concrete, and their application scenarios continue to expand

In terms of water conservancy, it is commonly used for lining small water channels, drainage ditches, and treating the inner walls of reservoirs. Compared to traditional concrete pouring, it does not require formwork and can closely fit the curvature and concave convex surface of the base layer, especially suitable for irregular ditches next to terraced fields in mountainous areas; The waterproof barrier formed after hardening has an extremely low permeability coefficient, which can reduce the water leakage rate to less than 1/10 of traditional processes. At the same time, the fiber skeleton enhances the impact resistance, which can resist the erosion of seasonal floods on the canal wall and extend the service life of water conservancy facilities.

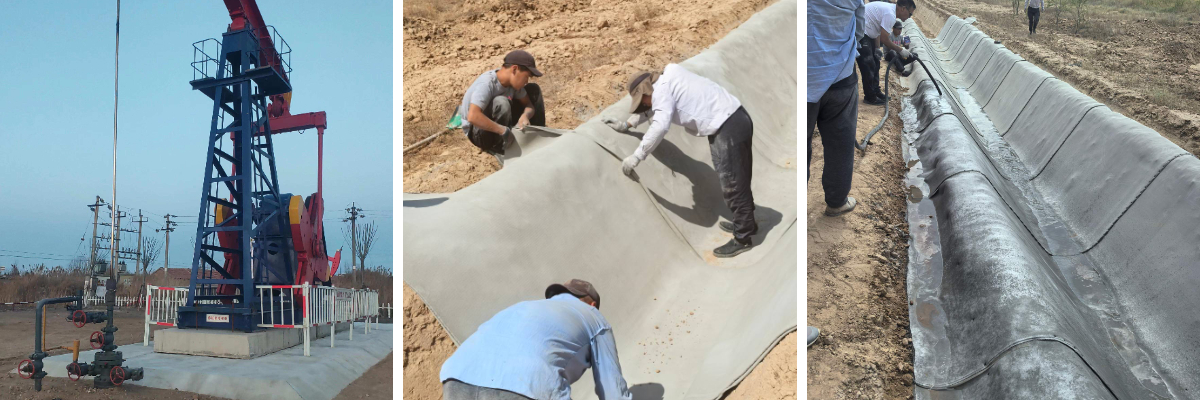

In the field of transportation, in the protection of highway and railway slopes, it can cover uneven slopes like cloth, and harden into a comprehensive protective layer within 24 hours after watering to prevent rainwater from seeping into the slope along the gaps and causing landslides; When laying temporary access roads and emergency passages, the weight of a single roll is only a few tens of kilograms, and 2-3 people can quickly deploy it. Compared with sand and gravel paving, it saves more than 70% of construction time, and the compressive strength of the hardened road surface can reach 15MPa, meeting the emergency traffic needs of small vehicles.

In agriculture, as an inner lining material for irrigation channels, its sealing performance can reduce water resource infiltration loss by more than 40%, making it particularly suitable for water-saving irrigation projects in arid northwest regions; In the construction of small-scale water reservoirs in farmland, there is no need for vibration and maintenance, and they can be directly laid and watered to form. The construction cost per acre is reduced by 30% compared to traditional brick ponds, and the frost resistance is better than ordinary concrete, which can adapt to the cold climate in the north.

In emergency scenarios, when facing a river embankment surge, the appropriate size can be quickly cut to cover the leakage point. Within 30 minutes after watering, it can be preliminarily solidified to form a sealing layer, which can be quickly controlled by using sandbags to apply pressure; When repairing road collapses, the temporary base layer formed after laying can carry rescue vehicles and buy time for subsequent permanent repairs.

In general, cement blankets combine the performance advantages of traditional building materials with convenient construction characteristics through material innovation, effectively solving the problems of low efficiency, high cost, and poor adaptability of traditional processes in small-scale and emergency projects, and becoming an important choice to improve the flexibility and economy of engineering construction.