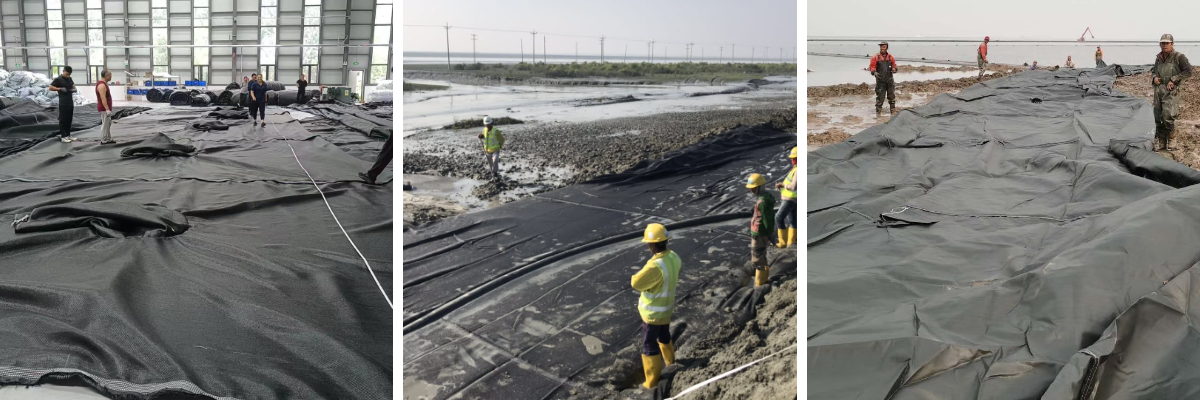

Customized Geotextile Tubes

1.Efficient Solid-Liquid Separation:Can quickly intercept solid particles, achieve efficient separation of mud and water, and greatly improve processing efficiency.

2.Strong Bearing Capacity:Able to withstand high internal pressure, with stable structure after being filled with materials and not easy to be damaged.

3.Simple and Fast Construction:Light in weight and good in flexibility, can be quickly hoisted, laid and filled, shortening the construction period.

4.High Material Utilization Rate:Made of high-strength geotextile, can be customized in size according to engineering needs, reducing material waste.

5.Wide Adaptability:Suitable for various scenarios such as river dredging, sea reclamation, and municipal sludge treatment.

6.Good Economy:Long service life, less later maintenance, low comprehensive cost, and outstanding cost performance.

Product Introduction

1.Materials and Structure

Customized Geotextile Tubes is made of high-strength geotextile fabric made by special technology as raw material. This fabric is wear-resistant, corrosion-resistant, and has excellent tensile strength and permeability. It can maintain stable performance in complex acid-base environments, high and low temperature alternation and other working conditions. Through professional double line sewing and even multi line reinforcement processes, the fabric is made into a well sealed tubular bag body, with a length ranging from tens of meters to hundreds of meters, and a diameter that can be flexibly customized to several meters to tens of meters according to the amount of filling materials and engineering space requirements. It can accurately adapt to different construction environments such as rivers, coasts, and factories.

2.Core role

When filling bags with liquid containing materials such as mud, municipal sludge, and dredging waste, the microporous structure of geotextiles acts like a "sieve", allowing water molecules and small molecule impurities to quickly seep out through the pores, while solid substances such as sediment particles and organic residues are firmly trapped, achieving efficient solid-liquid separation. Data shows that the solid-liquid separation efficiency of high-quality geotextile bags can reach over 80%, and the moisture content of materials can be reduced from over 90% to below 60% in a short period of time. At the same time, as the moisture is continuously discharged, the material inside the bag gradually solidifies, forming a structure with high compressive strength. The radial compressive capacity can reach several tons per square meter, which can not only stabilize the foundation and raise the embankment elevation, but also resist water flow erosion, wave impact, and reduce risks such as soil erosion and bank slope collapse.

Product Parameters

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Application

1.River Dredging Field

In river dredging projects, geotextile tube bags can efficiently handle the fluid sludge generated from dredging. By filling with sludge and utilizing their solid-liquid separation properties, they quickly convert fluid sludge into solid cake, significantly reducing the transportation volume and avoiding sludge leakage during transportation that pollutes the surrounding environment. The treated sludge cake can also be used for land reclamation or brick-making, realizing resource reuse, which not only solves the problem of sludge disposal but also takes into account environmental protection and resource recovery.

2.Coastal Reclamation Engineering

Geotextile tube bags play a key role in coastal reclamation. The tube bag dikes formed by continuous filling can quickly outline the land contour. Compared with the traditional rock dumping process, this method can not only shorten the construction period by more than 30% but also reduce the cost by about 20%. At the same time, the structure formed by the tube bags has strong stability, which can effectively resist seawater erosion and wave impact, laying a solid foundation for the subsequent formation and development of the land area.

3.Municipal Sludge Treatment

In municipal sludge treatment, geotextile tube bags are an ideal alternative to traditional processes. They do not require large equipment to be on duty, saving a lot of labor costs. During the treatment process, they can reduce the volume of dewatered sludge to 1/3 of the original, greatly reducing the disposal pressure of sludge landfilling or incineration. With simple operation and good solid-liquid separation effect, they make sludge treatment more efficient and economical, helping to improve the level of municipal environmental governance.

4.Embankment Reinforcement Projects

In embankment reinforcement projects, geotextile tube bags laid at the embankment foot or slope can effectively disperse the impact force of water flow. Combined with vegetation planting, they form a "ecology + engineering" composite protection system, increasing the erosion resistance of the embankment by more than 50%. This method not only enhances the stability of the embankment and extends its service life but also takes into account ecological protection, realizing the coordinated development of engineering protection and the ecological environment.

In general, the application of geotextile tube bags in fields such as river dredging, coastal reclamation, municipal sludge treatment, and embankment reinforcement, with their efficient, environmentally friendly, and economical characteristics, has significantly improved project efficiency and quality. They occupy an important position in modern engineering construction and provide strong support for the smooth implementation of various projects.