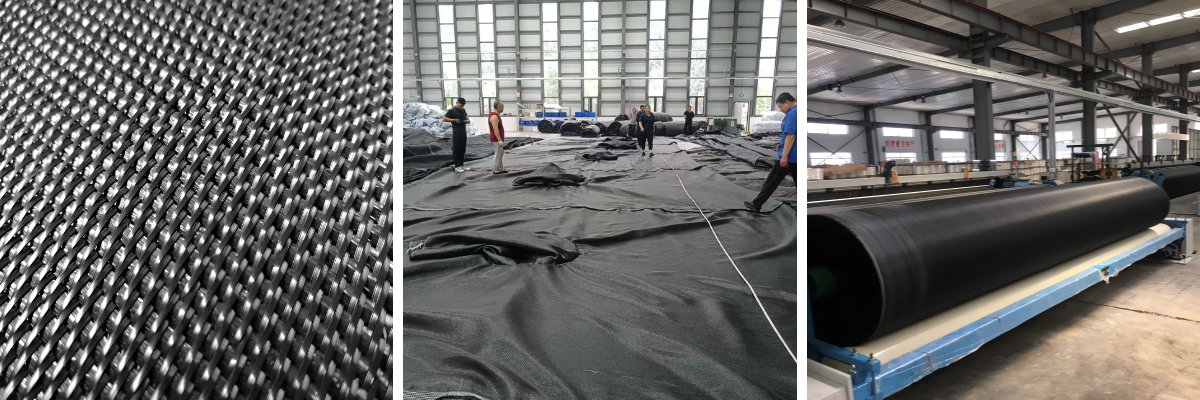

Geotextile Dewatering Bags

1.Stable structure and strong bearing capacity:

Sewn with high-strength geotextiles, featuring high tensile strength, capable of withstanding large pressure, effectively achieving earthwork constraint and water interception.

2.Flexible construction with convenient efficiency:

Can be customized in size according to engineering needs, directly laid after on-site filling with materials. Simple and fast construction significantly shortens the project duration.

3.Wide application and excellent adaptability:

Suitable for various scenarios such as river regulation, coastal protection, sludge dewatering, etc., showing good adaptability to complex terrains and harsh environments.

4.Eco-friendly and durable:

Materials are corrosion-resistant and anti-aging, with long service life.

Product Introduction:

Geotextile Dewatering Bags are tubular geosynthetic containers constructed from woven polypropylene yarns with a filtration structure. The Geotube dewatering and solidification method involves injecting a polymer flocculant solution at a specified dosage into dredged sludge during underwater excavation. The mixture is then pumped into the Geotubes, where it undergoes pressure filtration to remove water and consolidate, effectively reducing the volume of the sludge.

Functions and Characteristics

1.Drainage and Dewatering:

Geotextile tubular bags exhibit excellent filtration and permeability properties. When filled with sludge, water naturally seeps out through the bag walls, while sediment particles are retained inside, enabling the dewatering and solidification of the sludge.

2.Reinforcement and Isolation:

Geotextile tubular bags can serve as reinforcement materials to enhance soil stability. Additionally, they act as barriers to prevent the mixing of different soil layers.

3.Strong Durability:

These tubular bags demonstrate high resistance to ultraviolet (UV) radiation, acids, alkalis, and microbial erosion, ensuring long-term performance in harsh environments.

4.Plasticity and Stackability:

The diameter and length of geotextile tubular bags can be customized according to requirements, offering high flexibility. They are also stackable, facilitating convenient transportation and storage.

This translation maintains technical precision while ensuring clarity for an international audience.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1.Dewatering and subsequent disposal of contaminated sediment from dredging in rivers, lakes, reservoirs, seaports, docks, etc.

2.Municipal sludge treatment (sludge from water treatment plants and sewage plants), industrial sludge treatment (sludge from chemical, pharmaceutical, dyeing, and other industries);

3.Treatment of washing wastewater from livestock, poultry, and aquaculture farms (including fecal sewage), plantation wastewater treatment, and aquaculture bed waste disposal, etc.;

4.Treatment of fly ash and low-grade ash from power plants, desulfurization and dust removal sludge from steel mills, and sludge from aluminum plants and ceramic factories, etc.;

5.Treatment of mining and ore-washing wastewater along with waste recycling, and dewatering of slurry in construction projects, etc.;