Geotextile Fabric for Ponds

1. High strength: It has good tensile and tear resistance, and can enhance the stability of soil structure.

2. Permeability: allows water to pass through while effectively preventing soil particle loss, playing a filtering role.

3. Corrosion resistance: resistant to chemical corrosion, acid and alkali, suitable for various complex environments.

4. Durability: UV resistant, anti-aging, long service life.

5. Convenient construction: lightweight, easy to cut and lay, can greatly improve construction efficiency.

Product Introduction:

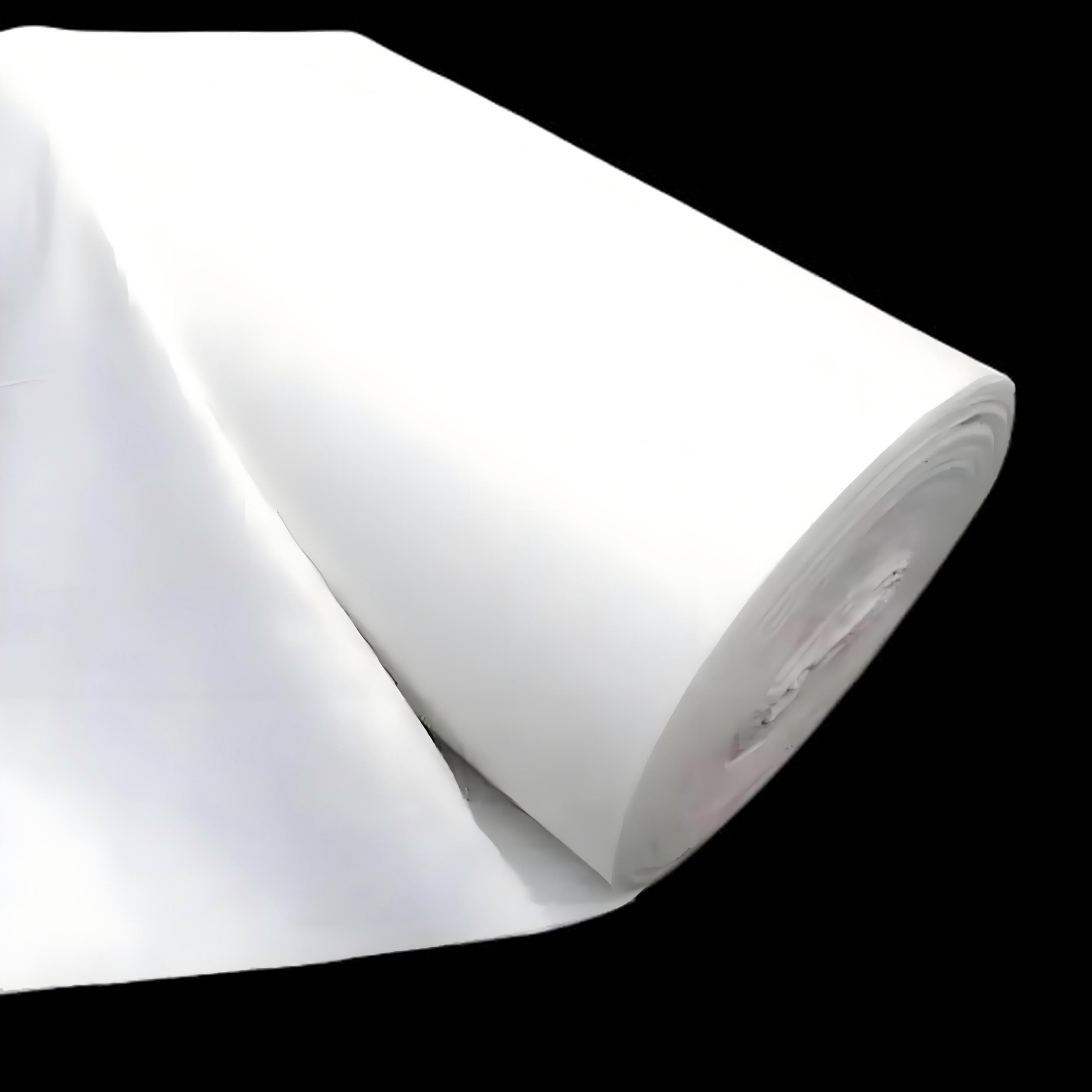

Geotextile Fabric for Ponds is a permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. Its finished product is in the form of cloth, with a width of usually 4-6 meters (some up to 9 meters) and a length of 50-100 meters. It is divided into two categories: woven geotextile (high-strength) and non-woven filament geotextile (high permeability). As a core member of geosynthetic materials, geotextiles play the role of an "invisible protective net" in engineering, silently guarding structural safety and ecological balance.

key features

1. High strength and durability

Synthetic fibers endow geotextiles with excellent tensile strength (up to 20-200kN/m), which can maintain long-term stability even in harsh environments such as wet dry alternation and acid-base corrosion. For example, in coastal engineering, geotextiles can resist seawater erosion and have a service life of over 20 years.

The antimicrobial performance ensures that it is not damaged by insects or mold in humid environments, making it suitable for long-term protection of underground engineering.

2. Permeability and Filtration

The pores between fibers allow water to pass through, but effectively intercept soil particles, fine sand, etc., preventing soil erosion. In dam engineering, geotextile serves as an anti filter layer, which can avoid damage phenomena such as piping and soil flow, and improve structural safety.

Excellent drainage performance, can quickly dissipate soil pore water pressure, reduce liquefaction risk, and is suitable for foundation reinforcement in earthquake prone areas.

3. Construction convenience

The material is soft and easy to transport, lay, and sew. When hot bonding is not possible in rainy or snowy weather, anti UV suture can be used for double line sewing to ensure connection strength.

Complete specifications (unit area mass 100-1000g/m ²), customizable according to engineering needs, to meet the mechanical and permeability requirements of different scenarios.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

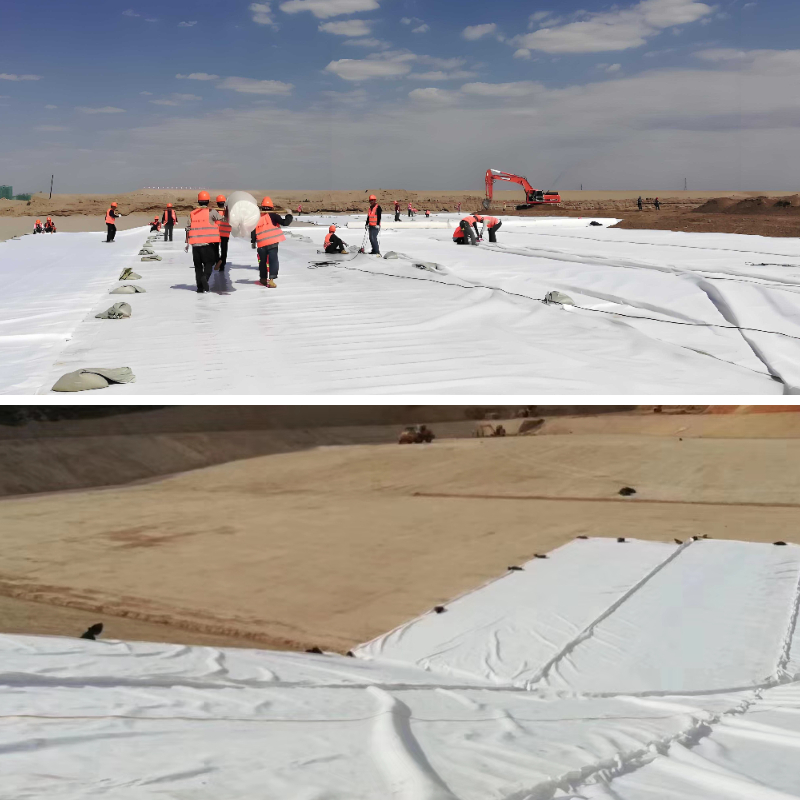

1. Water conservancy engineering

Dam protection: As a drainage layer behind the anti-seepage membrane, it dissipates pore water pressure; As an anti filter layer, it prevents infiltration damage.

Channel engineering: laid at the bottom and slope of the channel to reduce leakage, improve water delivery efficiency, and prevent erosion.

Water well and pressure relief well: serving as a filter layer to prevent wellbore collapse and extend the service life of the water well.

2. Transportation Engineering

Road base layer: Isolate aggregates of different particle sizes to prevent mixing and ensure the stability of the structural layer.

Railway track bed: Drainage isolation to prevent ballast from being embedded in the roadbed and reduce track deformation.

Airport runway: Enhance the bearing capacity of weak foundation and reduce uneven settlement.

3. Environmental Protection Engineering

Landfill site: Combined with geomembrane to form an anti-seepage system, preventing leachate from contaminating groundwater.

Wastewater treatment plant: used as a regulating tank, sedimentation tank anti-seepage layer, or biological filter material to improve treatment efficiency.

Soil remediation: Fixing polluted soil, preventing the spread of pollutants, and assisting in ecological restoration.

4. Civil and creative applications

Home gardening: Covering the soil surface to suppress weeds, ensuring breathability and permeability, and reducing weeding labor.

Emergency waterproofing: Temporarily cover roof leakage points to guide rainwater drainage and avoid indoor water accumulation.

Moving and storage: Wrap furniture corners to prevent scratches, and lay them at the bottom of the carriage to prevent goods from sliding.

Outdoor camping: laid under the tent to prevent moisture and mud, cut into picnic mats, lightweight and easy to clean.

Geotextiles have become an indispensable "all-around player" in modern engineering due to their five functions of "isolation, filtration, drainage, reinforcement, and protection". From the "hardcore responsibility" of supporting thousands of miles of highways to the "life assistant" of entering thousands of households, geotextiles prove with their strength that practical technology should be close to life. In the future, with the continuous advancement of material technology, geotextiles will demonstrate their unique value in more fields, creating a safer and more sustainable living environment for humanity.