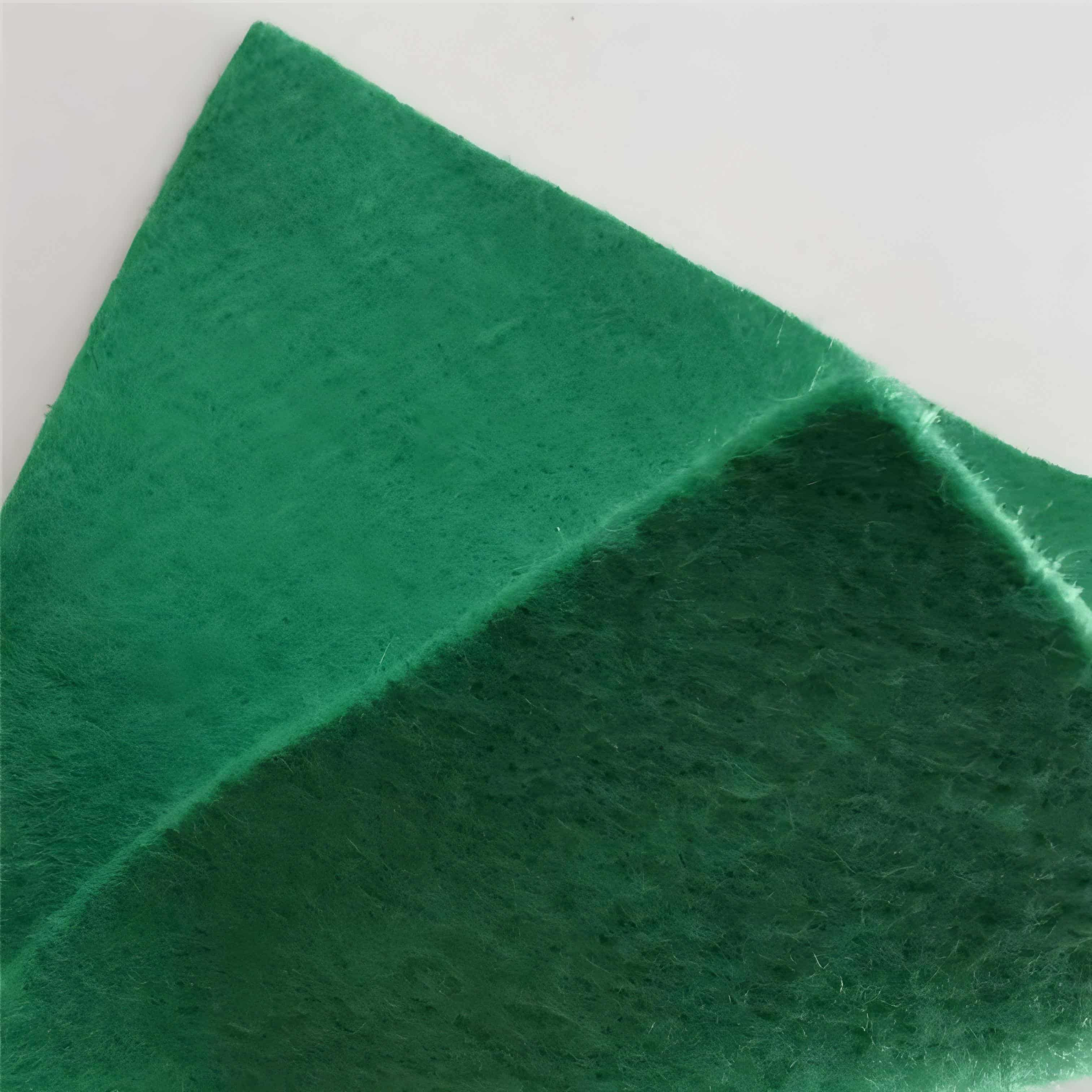

Geotextile Polyester

1. Strong tensile and tensile resistance: With the support of high-quality materials, it has strong fracture resistance and stabilizes engineering structures.

2. Permeable without soil erosion: The special structure allows water to flow smoothly and retains soil particles.

3. Outstanding weather resistance: not afraid of sun, rain, acid and alkali erosion, long-term performance will not be reduced.

4. Construction convenience: lightweight and flexible, can be cut or pieced together as needed, and can be laid out quickly.

5. Environmental protection and cost saving: The materials are recyclable, pollution-free, durable, and reduce repeated investment.

Products Introduction:

Geotextile Polyester is a new type of geosynthetic material made from polyester fibers as the core material, processed through advanced techniques such as needle punching and weaving. It combines the stability of polymer materials with the flexibility of fiber products, playing a key role in various civil engineering, water conservancy construction and other scenarios, and is one of the indispensable basic materials in modern engineering construction.

Product Features:

1. High tensile strength: Polyester fibers themselves have excellent mechanical properties, making the geotextile have extremely high tensile strength and tear strength, which can effectively resist the tensile force generated by soil pressure, external loads, etc., ensuring the stability of engineering structures.

2. Excellent permeability: The special fiber structure forms numerous tiny pores, allowing water to pass smoothly while also blocking the loss of soil particles, achieving dual functions of drainage and soil conservation.

3. Excellent weather resistance: Polyester materials have good acid and alkali resistance, UV resistance, and aging resistance. They can maintain stable performance for a long time in complex environments such as sunlight, rain, humidity, and heat, extending the service life of the project.

4. Construction convenience: The material is lightweight and flexible, and can be cut and spliced according to engineering needs. The laying process is simple and efficient, which can greatly shorten the construction period and reduce construction difficulty.

5. Environmentally friendly and economical: produced using environmentally friendly polyester raw materials, with no harmful substance release, meeting environmental protection requirements; At the same time, its durability is strong, which can reduce the frequency of maintenance and replacement in the later stage, and lower the overall cost of the project.

Product Parameters:

| project | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

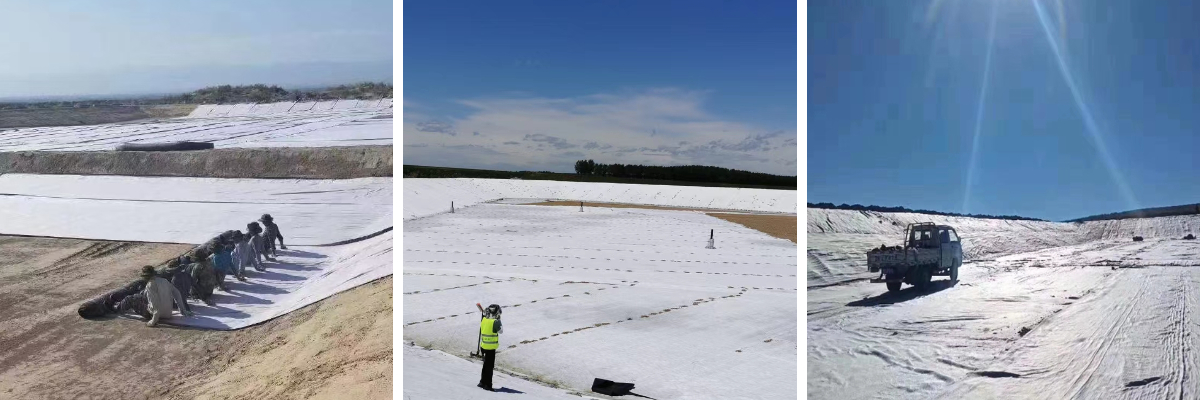

1. Water conservancy engineering: In projects such as dams, channels, and waterways, it can be used for anti-seepage, drainage, and reinforcement of embankments to prevent soil erosion and dam collapse, and to improve the safety and stability of water conservancy facilities.

2. Highway and railway construction: Laying in the roadbed can enhance the bearing capacity of the roadbed, reduce roadbed settlement and deformation, and also serve as drainage to protect the roadbed from damage caused by rainwater immersion.

3. Municipal engineering: In urban roads, underground parking lots, sewage treatment plants and other projects, it can be used for filtration, isolation, drainage, improving the structural performance and usage effect of the project.

4. Environmental engineering: In landfills, it can serve as an auxiliary material for anti-seepage layers to prevent soil and groundwater pollution caused by leachate from garbage; In the construction of artificial wetlands, it contributes to water cycling and soil stability.

5. Agriculture and Horticulture: Used for anti-seepage and drainage of irrigation channels in farmland, as well as soil improvement and drainage system construction in greenhouses and landscaping.

Geotextile Polyester geotextile has significant advantages such as high strength, good permeability, strong weather resistance, convenient construction, environmental protection, and economy. It has been widely used in various fields such as water conservancy, highways, municipal engineering, environmental protection, and agriculture. It can not only improve engineering quality and stability, but also reduce engineering costs. It is a high-performance and practical geosynthetic material that provides reliable material support for various engineering constructions.