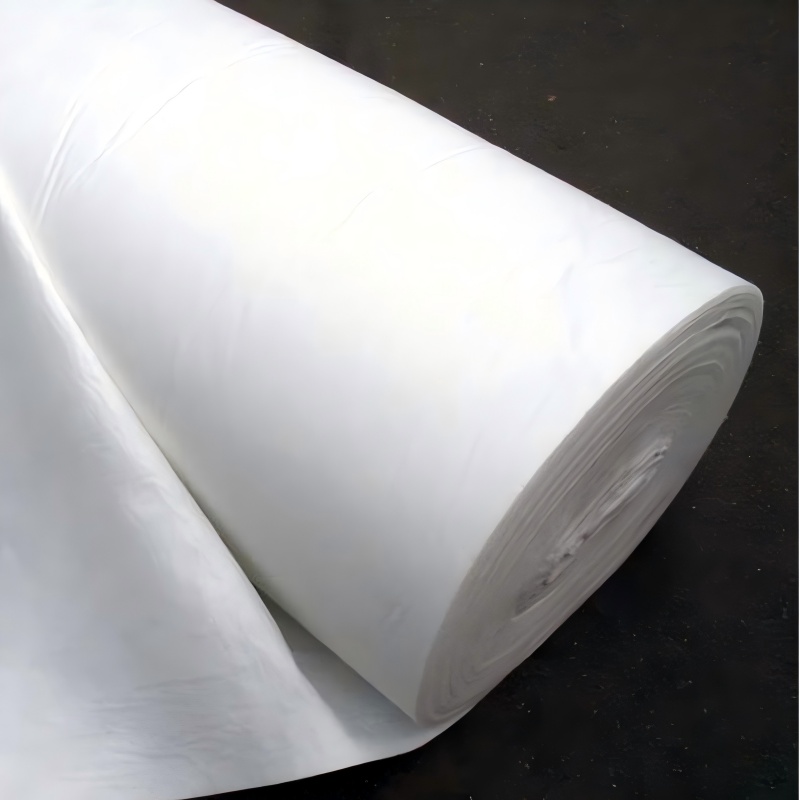

Geotextile 160g m2

1. Strong durability:

Synthetic fibers are resistant to chemical corrosion, microbial degradation, and have a long service life.

2. Convenient construction:

lightweight, easy to cut, and adaptable to complex terrains.

3. High cost-effectiveness:

Compared to traditional materials such as sand and concrete, the cost is lower and maintenance is simple.

4. Environmental friendliness:

Recyclable and reduces dependence on natural resources.

Product Introduction:

Geotextile 160g m2 is a permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. Its finished products are in the form of cloth, with a width usually ranging from 4-9 meters and a length of up to 50-100 meters. They are divided into two categories: woven geotextiles (woven structures) and non-woven geotextiles (needle punched or heat bonded structures).

key features

1. Physical properties

Tensile strength: Non woven fabric has uniform tensile strength and outstanding deformation resistance with a woven mesh structure.

Permeable rate: The porosity is as high as 60% -90%, and the drainage efficiency far exceeds traditional materials.

Temperature resistance: resistant to high temperatures and freezing, suitable for extreme environments ranging from -50 ℃ to 150 ℃.

2. Chemical stability

Acid and alkali resistant, UV resistant, and stable in humid or chemically polluted environments.

3. Functional segmentation

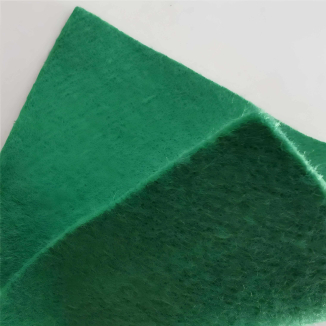

Short fiber needle punched type: soft and permeable, suitable for filtration and drainage scenarios.

Long filament spunbond type: high tensile strength, used for reinforcement and load-bearing engineering.

Composite type: such as the "cloth+membrane" structure, which has both anti-seepage and drainage functions.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Dam engineering

Anti filtration function: laid on the upstream face of the dam or inside the dam body, allowing water seepage to pass through while blocking soil particle loss, preventing the dam body from experiencing piping and collapse due to water flow erosion.

Anti seepage assistance: Used in conjunction with geomembranes to enhance the anti-seepage performance of dams, especially widely used in the anti-seepage structure of earth dams and rockfill dams.

Slope protection: Covering the surface of the embankment slope, combined with vegetation or stone blocks, to resist the erosion of waves and water flow on the slope.

River and Channel Engineering

River regulation: Geotextile is laid on the bank slope of the river, combined with materials such as gabion nets and ecological bags, to form a flexible protective structure that protects the riverbank from water erosion while also considering ecology (such as providing habitat space for aquatic organisms).

Channel anti-seepage and reinforcement: used for lining irrigation channels and water conveyance channels to reduce water leakage, prevent soil collapse on channel slopes, and extend the service life of channels.

2. Transportation Engineering

Highway and railway subgrade

Roadbed reinforcement: laid at the bottom of the roadbed, utilizing its high strength to disperse vehicle loads, reduce roadbed settlement and uneven deformation, especially suitable for soft soil foundation sections.

Isolation function: placed between the roadbed filling and the underlying layer (such as between soil and sand, different particle size filling), to prevent mixing of different materials and maintain the stability of the roadbed structure.

Drainage function: Drain the accumulated water in the roadbed through permeability, avoiding water retention and softening of the roadbed.

Road and track engineering

Road base isolation: It is laid between the road base and the sub base to prevent the base material from mixing with the sub base soil due to rainwater infiltration, and to avoid cracks and collapses on the road surface.

Track bed filtration: It is laid under the railway track bed to block soil particles from entering the track bed and discharge accumulated water, protecting the stability of the track bed structure.

3. Municipal and Environmental Engineering

Landfill site

Auxiliary anti-seepage system: As a protective layer for the anti-seepage layer (geomembrane) of the landfill site, it prevents sharp garbage from puncturing the geomembrane and also plays a role in filtering the leachate.

Leachate collection: laid on the bottom drainage layer of the landfill site, guiding the leachate into the collection system to avoid polluting the surrounding soil and groundwater.

underground engineering

Underground pipe gallery: wrapped around the pipe gallery to provide drainage and isolation, prevent soil erosion around the pipe gallery, and reduce the pressure of groundwater on the pipe gallery structure.

Tunnel engineering: laying between the initial support and secondary lining of the tunnel to discharge water seepage from the surrounding rock and protect the lining structure.

Wastewater treatment and ecological restoration

Artificial wetland: As a cushion or filter layer at the bottom of the wetland, it prevents the loss of wetland substrate, promotes water circulation, and assists in purifying water quality.

Black and odorous water treatment: used for covering river sediment or ecological floating island base, isolating polluted sediment, and improving water environment.

4. Building and foundation engineering

foundation treatment

Soft foundation reinforcement: By utilizing the tensile strength of geotextiles, the foundation load is dispersed over a larger area, and combined with a sand cushion layer to accelerate the drainage and consolidation of soft soil, the bearing capacity of the foundation is improved.

Foundation isolation: Lay on the surface of poor foundations such as miscellaneous fill and construction waste, isolate impurities from the upper structure filling, and avoid uneven settlement of the foundation.

Building backfilling

Wall and foundation pit backfilling: Lay geotextile in the backfill soil around the exterior wall or foundation pit of the building to isolate the backfill soil from the structural wall, prevent soil particles from blocking the drainage holes of the wall, and reduce the pressure of the backfill soil on the wall.

5. Slope and Ecological Engineering

slope protection

Rock and soil slope reinforcement: Combined with anchor rods, grids, etc., a composite protection system is formed to enhance slope stability and prevent landslides and collapses (such as highway slopes and mine greening slopes).

Soil erosion prevention and control: Lay geotextile on the surface of exposed slopes, cover the soil and fix vegetation seeds to promote vegetation growth and achieve ecological slope protection.

Agriculture and Horticulture

Agricultural water conservancy: used for anti-seepage and drainage of terraced fields and irrigation ditches, reducing water resource waste and preventing soil erosion.

Horticultural planting: As an inner lining material for flower pots and planting bags, it filters excess water while maintaining soil fertility.

The application scenarios of geotextiles are still expanding, and their core value lies in simplifying engineering design, reducing costs, and balancing engineering safety and ecological protection through the multifunctionality of materials. Different types of geotextiles need to be selected according to specific engineering requirements to maximize their effectiveness.