Sludge Dewatering Solutions

1. Durable materials: The geotextile bag is made of high-strength geotextile, which has strong resistance to ultraviolet radiation, chemical corrosion, and microbial erosion. It has good wear resistance in complex environments such as riverbanks and coasts, and can be used stably for a long time.

2.Flexible size: Its diameter can be adjusted as needed, and the volume adjustment range is large. It can be customized according to the space size of different sites and the required volume of the project.

3.Convenient construction: The operation is simple, the required supporting facilities are few, and it can be directly constructed in complex terrains such as underwater without the need to build cofferdams, greatly shortening the construction period.

4.Environmentally friendly and efficient: In the treatment of sludge and sludge, the solid retention rate is high, and the harmful elements in the filtered water are greatly reduced, meeting the standards for discharge or recycling.

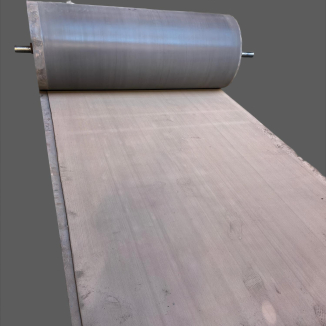

Products Introduction:

Sludge Dewatering Solutions is a large tubular structure carefully sewn from high-strength geotextile fabric. Its material is mostly made of high toughness polypropylene, which not only endows the tube bag with excellent physical properties, but also gives it good chemical stability. The diameter and length of the pipe bag can be flexibly customized according to the actual needs of the project, with a wide range of volume changes. Whether it is a large-scale water conservancy project or a small-scale river regulation project, suitable size specifications can be found. In terms of production technology, special weaving and sewing techniques are used to ensure the stability and reliability of the overall structure of the tube bag.

Product Features:

1. High strength and durability: The geotextile made of high toughness polypropylene material has a tensile strength of 50-200kn/m and can withstand significant pressure and tension. Resistant to ultraviolet radiation, chemical corrosion, and microbial erosion, it can still be used stably for a long time in harsh environments, greatly reducing the cost of replacement in the later stage.

2. Efficient drainage: The fabric pore structure is precisely designed, and the equivalent pore size is suitable. When filling materials, the liquid pressure inside the bag and its own filtering structure are used to quickly achieve the separation of mud and water. For example, in the sludge dewatering project, the sludge volume can be reduced by more than 90% within one month, and the dewatered clean water can meet the discharge standards or be recycled.

3. Convenient construction: After folding, it has a small volume and light weight, making it easy to transport and handle. The construction operation is simple, with low requirements for personnel's professional skills, and does not require large and complex equipment, resulting in low power consumption. It can be directly constructed in complex terrains such as underwater without the need to build cofferdams, greatly shortening the construction period.

4. Flexible size: Whether it is a small local protection project or a large sea reclamation project, it can provide suitable size and strong engineering adaptability.

5. Green environmental protection: In the treatment of sludge and sludge, the solid retention rate is high, and the harmful elements in the filtered water are greatly reduced, which can meet the discharge or recycling standards. The solidified sediment can be reused, such as as as backfill soil and green soil, which conforms to the concept of green environmental protection and sustainable development.

6. Affordable: Convenient construction reduces equipment, labor, and construction costs, while durable products reduce maintenance and replacement costs in the later stages. In large-scale projects, compared to traditional materials, it can save a lot of money and achieve significant economic benefits.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1. Embankment protection: It can be used for the protection and reinforcement of temporary or permanent dams and river embankments. By filling materials such as sand and soil, the stability of the dam is enhanced, and it can resist hazards such as floods and water flow erosion, playing an important role in flood control during river flood season.

2. Land reclamation and cofferdam engineering: In land reclamation and artificial island construction, geotextile bags can be used as cofferdam structures. By utilizing its ability to obtain local materials (such as extracting seabed sediment for filling), a closed cofferdam space can be quickly constructed, creating conditions for subsequent land development and infrastructure construction.

3. Sludge dewatering treatment: widely used for sludge treatment in rivers, lakes, and seas, as well as municipal and industrial sludge treatment. Fill the sludge into geotextile bags, and after efficient dewatering, significantly reduce the volume of sludge, making it easier for subsequent transportation and disposal. Dehydrated clean water can meet discharge standards or be recycled, and solidified sediment can also be used for secondary purposes such as green soil and backfill soil, achieving dual benefits of environmental protection and resource recycling.

4. Remediation of contaminated sites: In some contaminated soil areas, such as soil treatment contaminated with dioxins, geotextile bag technology can be used to build maintenance systems, filter the water in high moisture contaminated soil, retain pollutants in the bags, prevent their spread, and assist in the remediation of contaminated sites.

5. Beach protection and coastline protection: The geotextile bag is set perpendicular to the coastline, which can effectively prevent sand loss, resist the erosion of the beach and coastline by waves, protect the coastal ecological environment, promote the recovery and stability of the beach in its natural state, and reduce manual maintenance costs.

6. Wetland and ecological environment maintenance: Artificial coastlines can be constructed, with natural sedimentation of sea sand behind them, providing basic conditions for the formation and development of wetland ecosystems. At the same time, geotextile bags can be covered or directly exposed after UV protection treatment, providing all-weather soil and water conservation for the surrounding ecological environment.

Dredging And Dewatering Bags, with their unique product design and excellent product characteristics, have demonstrated significant advantages in many fields such as water conservancy, environmental protection, and coastal protection. Its characteristics of high strength, good drainage, easy construction, and flexible size not only provide reliable solutions for various projects, but also bring good economic and environmental benefits. With the continuous advancement of technology and the accumulation of application experience, geotextile bags will play a more important role in future engineering construction, continuously contributing to infrastructure construction, ecological environment protection and other undertakings.