Polypropylene Geotextile Tube Bags

Cost economy:The energy consumption is 60% lower than that of mechanical dewatering (such as plate and frame filter press), the transportation cost is reduced by 40% due to the volume reduction, and the comprehensive cost is decreased by 30% - 50%.

High - efficiency dewatering ability:It can handle mud with a moisture content of over 90%. The volume is reduced by 30% - 70% within 60 days, and the moisture content of the dried mud is reduced to 40% - 60%.

Structural adaptability:The flexible material can adapt to irregular terrains, and can save land occupation by stacking (height ≥ 2 meters), using 50% less land than traditional sludge storage ponds.

Environmental friendliness:Fully enclosed operation suppresses odors and dust, requires no large amounts of chemical agents, ensures the tail water meets standards, and enables the resource utilization of dry mud.

Product Introduction:

Polypropylene Geotextile Tube Bags are geosynthetic material product used for dredging and sludge dewatering treatment.

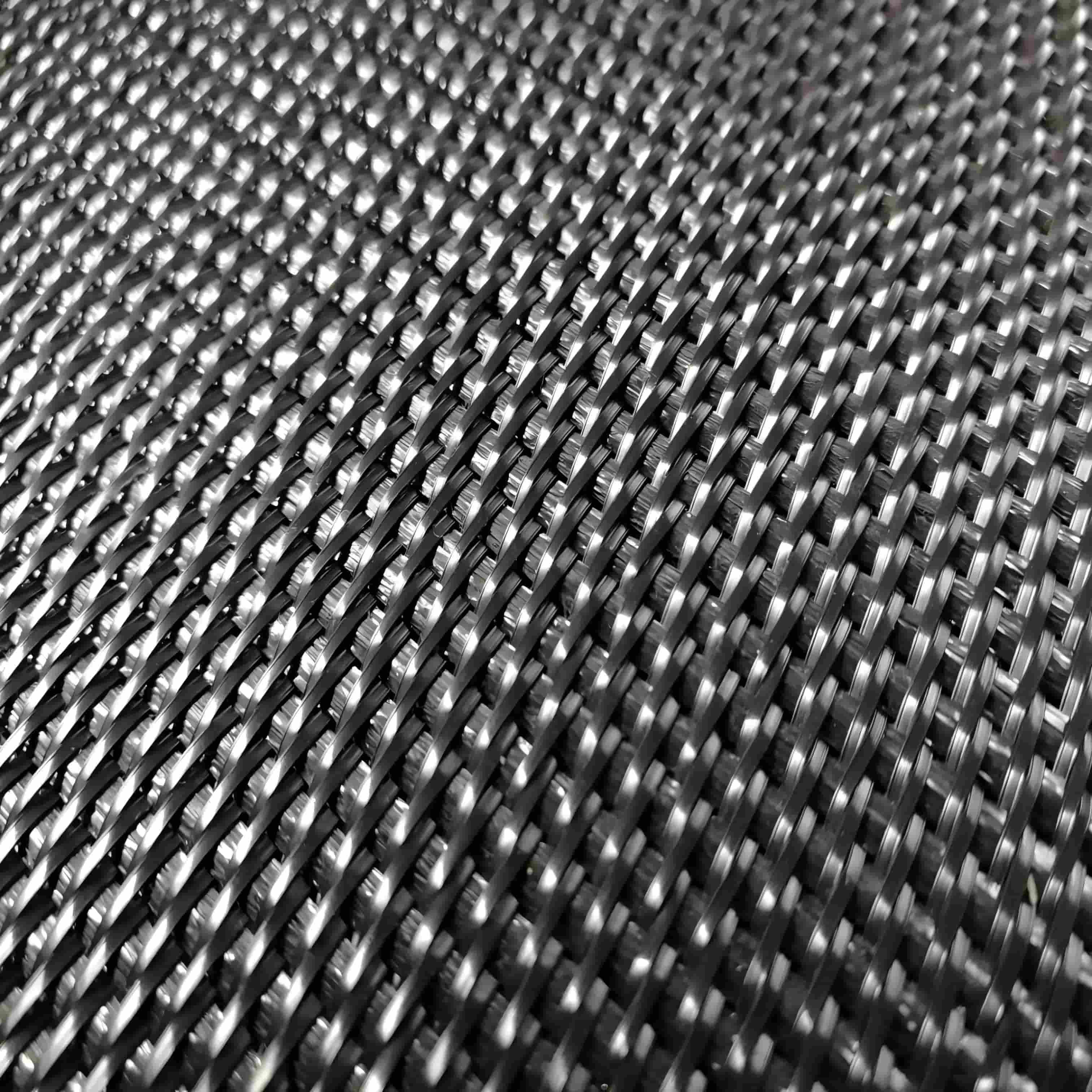

Structure and Material:It is usually made of materials such as high-strength polyethylene fiber and high-toughness polypropylene through a special weaving process. This kind of material endows the bag body with characteristics such as high strength (with relatively high tensile strength, and some can reach 45 - 300kN/m), UV resistance (greater than 90%/500h), and resistance to acid and alkali corrosion (PH2 - 13). Moreover, through special weaving, an equivalent pore size filtration structure is formed, which can effectively intercept fine particles.

Operating principle:Utilize the principle of natural gravity filtration or the liquid pressure inside the bag to pour the solid-liquid mixture containing silt, mud, etc. into the bag. Water seeps out through the small holes in the bag body, while solid particles are intercepted, precipitated, and solidified, achieving solid-liquid separation. In some cases, agents such as flocculants can be added to accelerate the process of separating mud and water.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

Water Conservancy and Water Environment Treatment

River and Lake Dredging: In dredging projects of rivers, lakes, reservoirs, etc., dewater the polluted bottom mud to reduce the volume of sludge for subsequent disposal, such as the dredging project of the Dianchi Lake sludge.

Coastal and Port Engineering: Dredge seaports and docks, handle the slurry generated from dredging, and it can also be used in coastal protection projects to fill sand to construct breakwaters, revetments, etc.

Black and Odorous Water Body Treatment: When treating black and odorous water bodies such as urban inland rivers, treat the river bottom mud, reduce the pollutant content, and improve the water environment.

Municipal and Industrial Fields

Sewage Treatment Plants: Treat the sludge generated by water treatment plants and sewage treatment plants, achieve sludge reduction and stabilization, and reduce the cost and difficulty of subsequent disposal.

Industrial Sludge Treatment: For industrial enterprises such as chemical, pharmaceutical, printing and dyeing, steel, aluminum, and ceramic factories, treat various types of sludge generated during the production process to prevent the spread of pollution.

Mining - related Operations: Treat the wastewater from mining and ore washing, dewater and consolidate tailings, prevent heavy metal leakage, and recover useful substances; it can also be used for the neutralization and solidification of acidic mine mud.

Infrastructure Projects: Dewater and recycle construction mud such as shield mud and pile foundation surplus mud to avoid environmental pollution caused by random mud discharge.

Energy Field

Power Plant: Treat fly ash and low-ash, realizing rational waste disposal and potential resource recycling.

In environmental protection projects, Polypropylene Geotextile Tube Bags can not only efficiently solve pollution problems, but also achieve a sustainable closed loop of "treatment - reduction - reuse".