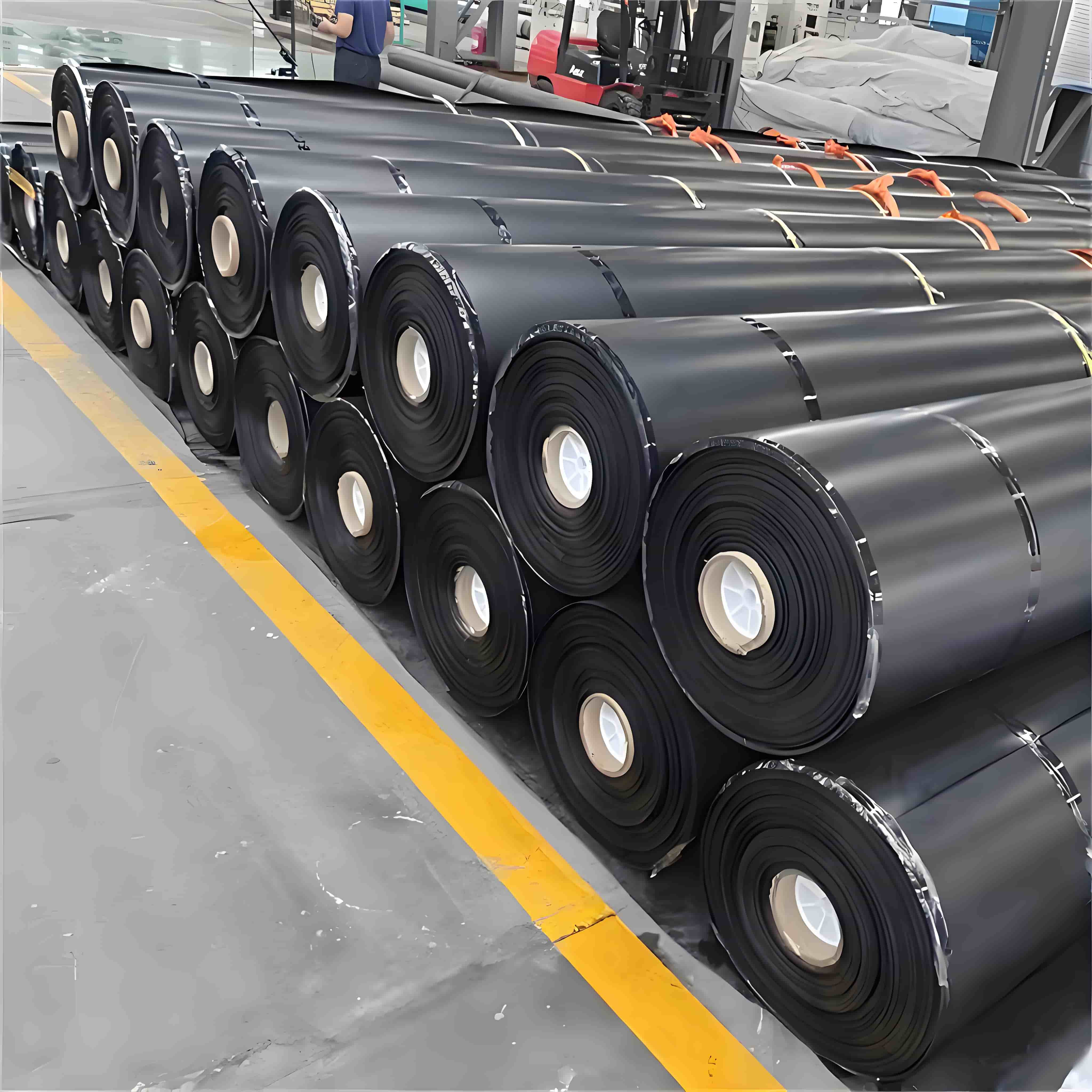

HDPE Dam Liners

1.Aging resistance and mechanical properties:

With added anti-UV agents, it has strong weather resistance), and features excellent tensile strength and puncture resistance, adapting to foundation deformation.

2.High impermeability:

With a low permeability coefficient (10⁻¹²~10⁻¹³ cm/s), it effectively blocks the seepage of water, liquids and gases.

3.Chemical corrosion resistance:

Resistant to acids, alkalis, salts and other media, suitable for corrosive environments.

Product Introduction:

HDPE Dam Liners are geosynthetic material with high - molecular polymers as the basic raw material. It has excellent properties such as anti - seepage, isolation, and corrosion resistance, and plays a key role in various projects.

Main Raw Materials

High - molecular Polymers: Such as high - density polyethylene (HDPE), low - density polyethylene (LDPE), ethylene - vinyl acetate copolymer (EVA), polyvinyl chloride (PVC), etc. In addition, there are modified products of synthetic rubber (such as neoprene) and natural high - molecular materials (such as asphalt).

Additives: To improve performance, antioxidants, light stabilizers, flame retardants, anti - aging agents, etc. are often added to enhance weather resistance, UV resistance and service life.

Core Features

Seepage Resistance: The molecular structure is compact, and the water permeability rate is extremely low (for example, the permeability coefficient of HDPE geomembrane is ≤1×10⁻¹² cm/s), which can effectively block liquid penetration.

Corrosion Resistance: It has strong resistance to chemical substances such as acids, alkalis, and salts, and is suitable for complex environments such as sewage and landfill leachate.

Mechanical Properties: It has high tensile strength, elongation at break, and puncture resistance, and can adapt to foundation deformation.

Weather resistance: Resistant to ultraviolet rays and aging. The service life can reach 10 - 50 years in outdoor or underground environments (depending on the material and usage scenario).

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

Environmental Protection Projects

Landfill: Laying multiple layers of geomembranes (often used in combination with bentonite mats, etc.) at the bottom and slopes of the landfill to form a seepage prevention system and prevent landfill leachate from contaminating groundwater and soil.

Sewage Treatment Plant: The anti-seepage treatment of sewage treatment tanks and regulating tanks to avoid sewage leakage from polluting the surrounding environment and to isolate the corrosive liquid from damaging the tank body at the same time.

Waste Residue Disposal Site: The anti-seepage project of industrial waste residue and hazardous waste landfills to prevent the penetration and diffusion of harmful substances and meet environmental protection standards.

Water Conservancy Projects

Reservoirs and Dams: Used for seepage control of reservoir dam bodies and dam foundations, preventing water leakage and ensuring the safety of dams. For example, laying geomembranes on the upstream face of a reservoir can effectively block water from seeping into the interior of the dam body.

Channels and Irrigation Projects: Channel seepage control is a typical application of geomembranes in water conservancy, which can reduce water loss during water conveyance and improve irrigation efficiency. Such as the lining seepage control of farmland irrigation channels and drainage channels.

Reservoirs and Artificial Lakes: Laying geomembranes on the bottom and slopes of artificial lakes and reservoirs can prevent water leakage, maintain stable water levels, and at the same time isolate pollutants in the soil to protect water quality.

Agricultural Engineering

Agricultural Anti-seepage Project: Anti-seepage at the bottom of fish ponds and shrimp ponds to prevent water leakage, maintain the breeding water level, isolate harmful substances in the soil, and protect the aquaculture environment.

Saline-alkali Land Improvement: Lay geomembranes on saline-alkali land to block the rise of underground brackish water, and cooperate with the drainage system to improve the soil salinization problem.

Agricultural Water Storage Project: Anti-seepage of small reservoirs and irrigation storage ponds to improve the utilization rate of water resources and meet the agricultural water demand in arid areas.

Mining Engineering

Mine Anti-seepage: Anti-seepage treatment of mine pits and slag yards to prevent the seepage of mine water containing heavy metals and avoid soil and water pollution.

Metallurgical Engineering: Anti-seepage projects for wastewater treatment ponds and waste slag dumps in smelters to meet environmental protection discharge requirements.

Energy Engineering

Oilfield Engineering: Anti-seepage of the foundation of oilfield drilling platforms and oil pollution treatment ponds to prevent oil spills from contaminating soil and groundwater.

Tailings Dam Engineering: The anti-seepage system of mine tailings storage sites to prevent the leakage of tailings wastewater and protect the ecological environment around the mining area.

Biogas Digester Engineering: Anti-seepage and sealing of the bottom and walls of biogas digesters to ensure the efficiency of biogas collection and prevent sewage leakage at the same time.