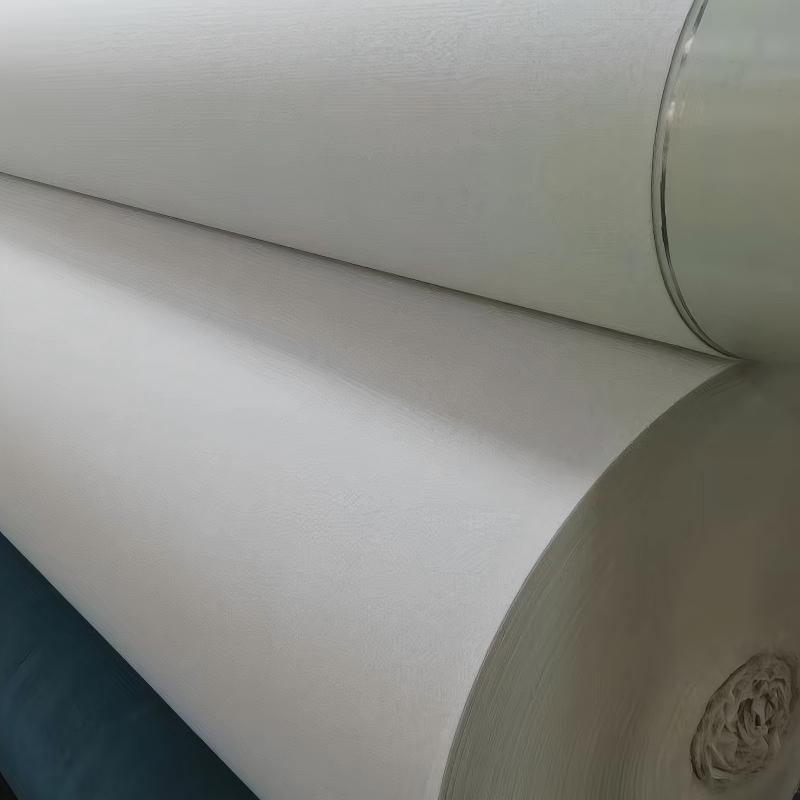

Non Woven Road Fabric

1.Stable roadbed: Resistant to tension, reduces settlement, and protects the roadbed

2.Quick drainage: Drain accumulated water, block blockages, and prevent softening

3.Interlayer mixing: Separate structural layers to avoid material degradation

4.Convenient construction: Roll laying, low cost, and time-saving construction period

Product Introduction

1. Basic attributes

Non Woven Road Fabric are made from high molecular weight materials such as polypropylene and polyester, and are processed through non-woven techniques such as needle punching and hot rolling to create a roll like geotextile. They possess high strength, porosity, and resistance to acid and alkali corrosion, and are suitable for structural layer scenarios such as road embankments and base layers.

2. Core functions

Load bearing strengthening: dispersing vehicle loads and reducing roadbed settlement and cracking;

Drainage and soil filtration: discharge accumulated water to prevent soil softening, block sediment and block channels;

Interlayer isolation: Avoid mixing materials from different structural layers to ensure functional stability.

3. Main features

Convenient construction: The roll form is easy to lay, shortening the construction period;

Economical and durable: light weight, low transportation cost, long anti-aging life;

Strong adaptability: It can be used in various road scenarios such as soft soil roadbeds and rural roads.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1.Roadbed reinforcement scenario: For roadbeds with weak bearing capacity such as soft soil and collapsible loess, non-woven road fabrics are laid inside the roadbed soil layer to disperse vehicle loads, reduce roadbed settlement and cracking problems, and especially suitable for low load roads such as rural roads and municipal branches, improving the overall stability of the roadbed.

2.Drainage filter layer scenario: Laying the fabric at the junction of the roadbed and cushion layer, or in the drainage channel of the road slope, using its porous structure to quickly drain the accumulated water inside the roadbed, avoiding soil softening and bearing capacity reduction caused by water retention; At the same time, it can prevent sediment from entering the drainage system and causing blockages, ensuring the continuous and effective drainage function. It is commonly found on roads and high fill roadbed sections in rainy areas.

3.Interlayer isolation scenario: It is laid between different structural layers of the road (such as subgrade soil and gravel cushion layer, base layer and asphalt/cement surface layer) to form a physical isolation barrier, prevent the cross mixing of different soil layers (such as fine soil invading the gravel layer), avoid material performance degradation, ensure the stable function of each structural layer, and is suitable for new construction and expansion projects of all levels of highways.

4.Slope protection scenario: Covering the surface of road slopes with fabric and using it in conjunction with vegetation planting can fix the soil on the surface of the slope, prevent soil erosion caused by rainwater erosion, buffer the damage of erosion to the slope, and improve slope safety. It is commonly used for slope protection on both sides of mountainous highways and expressways.

Non Woven Road Fabric, with their multifunctionality, are widely suitable for core scenarios in road construction such as roadbeds, drainage, interlayer isolation, and slope protection. They can provide solutions to pain points such as weak roadbeds and rainy environments, as well as meet the construction needs of different levels of roads. While improving the stability of road structures and extending their service life, they can also simplify the construction process, providing strong support for the economy and reliability of road engineering.