Geofabric for Driveway

1. Stabilizes the roadbed: Enhances soil bearing capacity, distributes vehicle loads, and prevents lane settlement, collapse, and cracking.

2. Filters and prevents clogging: Prevents fine soil particles from mixing into the gravel layer, while simultaneously draining accumulated water to prevent muddy and waterlogged roads.

3. Convenient construction: Easy to cut and lay directly between the subgrade and aggregate, requiring no specialized equipment, saving labor and time.

4. Long-lasting and durable: Resistant to compaction, UV radiation, and acid/alkali corrosion, extending the service life of the road and reducing maintenance frequency.

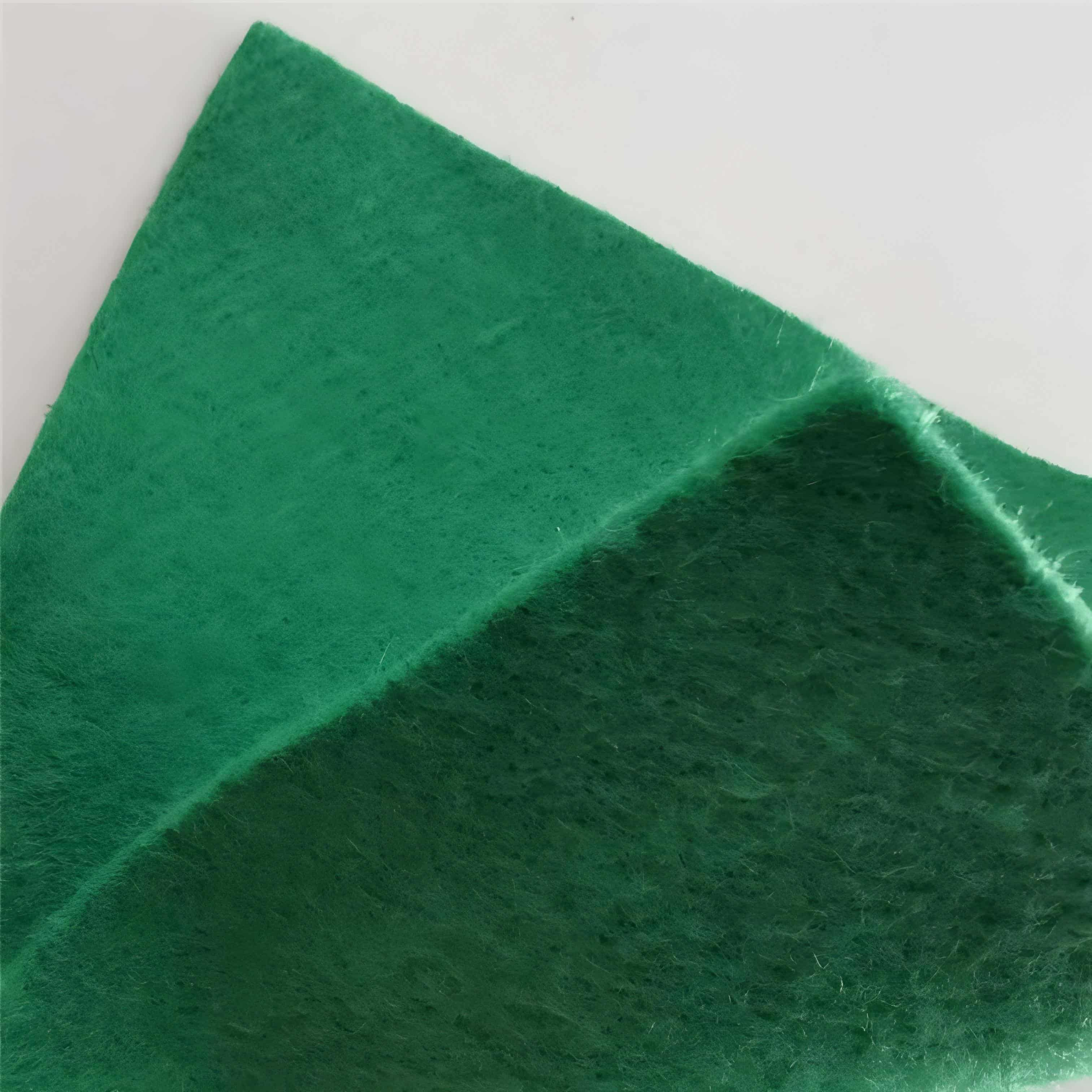

Products Introduction:

Geofabric for Driveway is a geosynthetic material designed specifically for the protection and reinforcement of lane base layers. It is made from high-strength polypropylene (PP) or polyester (PET) and processed through needle punched non-woven or machine weaving techniques. Some products undergo additional UV and abrasion resistance treatments. Its core function is to be laid between the lane base layer (gravel, asphalt or concrete cushion layer) and the underlying soil, solving the four major pain points of "mixed base layer, load settlement, poor drainage, and weed growth" in lane use. It provides stable base protection for scenarios such as household private lanes, rural lanes, and small parking lot lanes, which can not only improve the lane bearing capacity but also extend the service life. It is a cost-effective supporting material in lane construction and renovation projects.

Product Features:

1. Strong isolation and anti caking: The fabric pores are precisely designed (non-woven pore size 0.05-0.5mm, woven pore size evenly controllable), which can efficiently block the upwelling of fine particles (clay, silt) in the soil below, avoiding them from filling the gaps between the gravel/asphalt base of the lane and preventing the hardening of the base layer caking. At the same time, prevent the embedding of base materials into soft soil, maintain the loose structure of the base for a long time, and ensure the stability of the lane load-bearing and drainage foundation.

2. High tensile and reinforced load resistance: relying on a three-dimensional network of interwoven fibers (non-woven type) or a long filament weaving structure (woven type), it has excellent tensile strength (15-50kN/m) and tear resistance. After laying, it can disperse vehicle loads like an "invisible skeleton", especially the local pressure generated by heavy SUVs and trucks, reducing the settlement, depression or cracking of the lane base caused by heavy pressure, and adapting to daily high-frequency vehicle traffic scenarios.

3. Efficient drainage and water accumulation prevention: With good permeability, rainwater or surface water can quickly penetrate into the underground drainage system through geotextiles, while filtering sediment to prevent blockage of drainage channels. Compared to lanes without geotextile paving, the drainage efficiency is improved by more than 40%, avoiding roadbed softening, frost heave and cracking caused by rainwater accumulation at the base (in winter in the north), and ensuring the safety of lane traffic during the rainy season.

4. Weather resistance, grass resistance and easy maintenance: after anti ultraviolet and anti-aging treatment, outdoor exposure can withstand direct sunlight, rain immersion, high and low temperature changes (-30 ℃ to 70 ℃), with a service life of 8-15 years. At the same time, physical barriers are used to prevent weeds from penetrating the lane base, avoiding the growth of weeds through the gaps in the lane. This eliminates the need for frequent manual weeding or herbicide spraying, significantly reducing the daily maintenance costs and workload of the lane.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Household private lane: In the construction of private lanes (made of gravel, asphalt or concrete materials) in villas and self built houses, they are laid between the base layer and soil to isolate and prevent compaction while enhancing the load-bearing capacity of the base layer, avoiding local settlement of the lane caused by long-term parking of household vehicles; The efficient drainage function can prevent rainwater from accumulating and affecting the entry and exit of vehicles, keeping the lane clean and beautiful.

2. Rural and suburban lanes: Rural road branches and suburban residential area lanes are often paved with crushed stone or simple asphalt. Laying this geotextile can solve the problem of soft and fine-grained soil in rural areas and prevent mixed compaction of the lane base; The reinforcement performance improves the lane's resistance to deformation, meets the needs of agricultural machinery and truck traffic, and reduces the frequency of lane renovation.

3. Small parking lot lanes: small parking lot lanes inside the community and in front of shops, with frequent and diverse types of vehicle entry and exit. Laying geotextile can disperse the load of different vehicle types and reduce cracking and arching caused by long-term compaction of the lanes; The grass blocking feature prevents weeds from affecting the aesthetics of the parking lot and reduces property maintenance costs.

4. Lane renovation and repair: When renovating old lanes, they should be laid between the original base layer and the newly laid material to isolate the old and new base layers and prevent impurities from affecting the performance of the new layer; For lanes with local settlement and cracking, geotextile can be used for local reinforcement and repair to improve the stability and durability of the repaired lane and extend the secondary renovation cycle.

Geofabric for Driveway precisely solves the pain points of grassroots stability and durability in various lane engineering projects with its four core advantages of "isolation and anti plate structure, reinforced load resistance, efficient drainage, and weather resistance and easy maintenance". It can not only ensure the integrity of the lane base structure from the source, improve the lane bearing capacity and wear resistance, but also adapt to multiple lane scenarios such as household, rural, and parking lots, balancing practicality and economy. Whether it is the basic protection of newly built lanes or the renovation and reinforcement of old lanes, this product can provide reliable support for lane engineering with "low cost investment and high value return", reducing maintenance troubles in the later stage and extending the service life of lanes. It is an ideal supporting material for creating durable and low maintenance lanes.