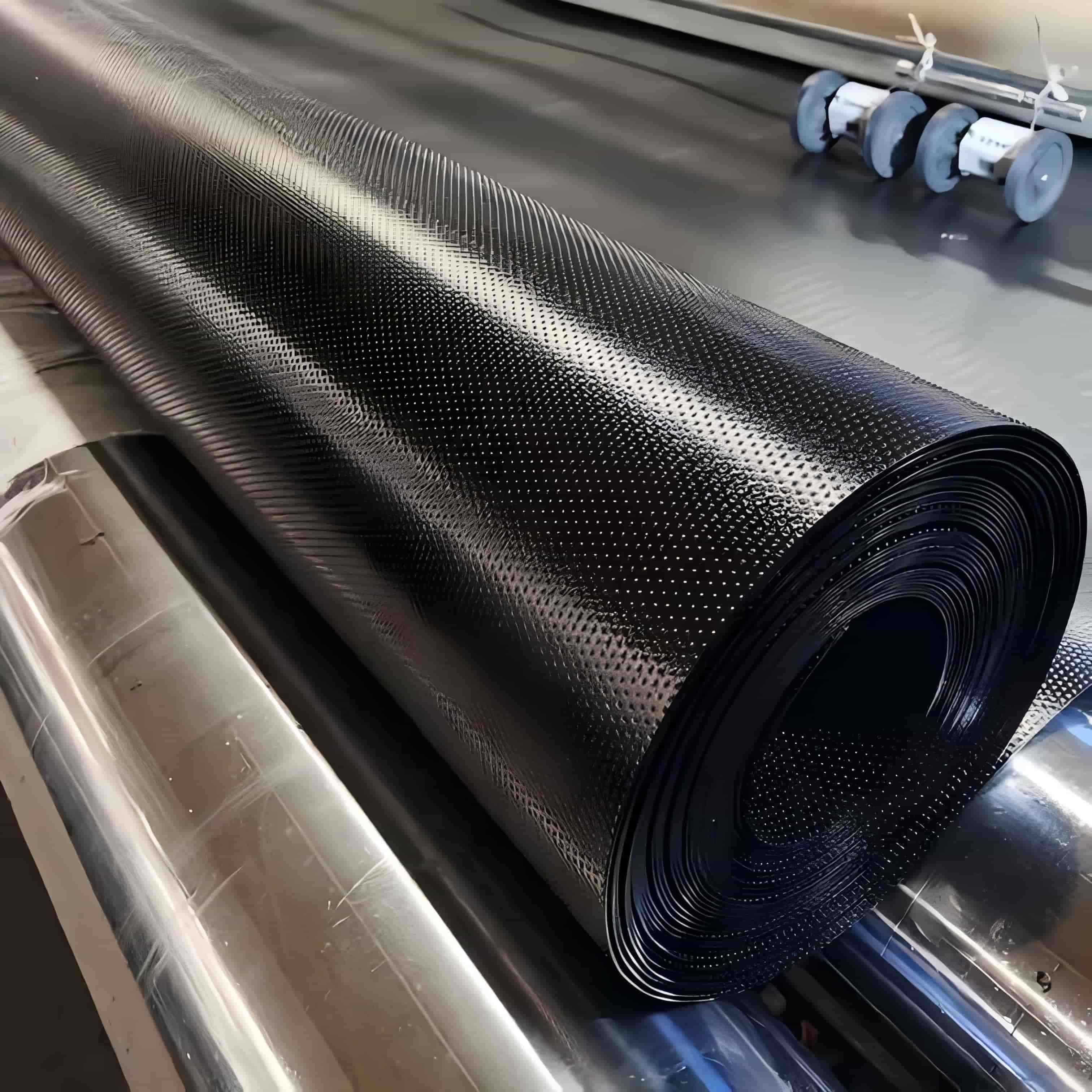

Geomembrane Fabric

1.Excellent Impermeability:

Extremely low permeability coefficient, effectively preventing the penetration of water, chemicals, or pollutants.

2.Chemical Corrosion Resistance:

Resistant to acids, alkalis, salts, oils, and various other chemical substances.

3.Aging Resistance & Durability:

With added UV stabilizers, it can be used for long-term exposure, with a service life of up to 50 years.

4.Easy Construction:

Lightweight, weldable or bondable, adaptable to complex terrains.

5.Cost-Effective:

More economical and easier to maintain compared to traditional concrete impermeable structures.

Product Introduction:

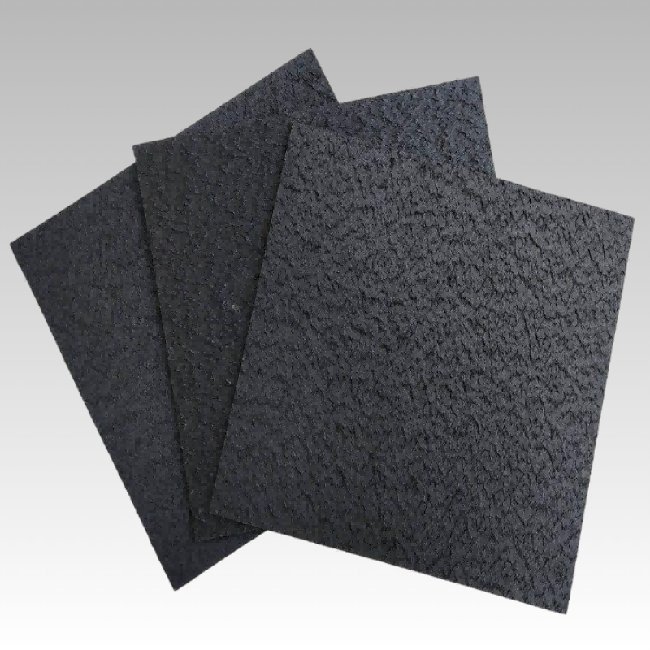

Geomembrane Fabric is flexible waterproof materials manufactured primarily from synthetic resins (such as polyethylene, polyvinyl chloride, etc.) through processes like blow molding, calendering, or casting. They typically feature single-layer or multi-layer structures with smooth or textured surfaces, effectively preventing the penetration of liquids, gases, or solid particles. Geomembranes are often used in combination with materials like geotextiles and geogrids to form composite geomembranes, enhancing their tensile strength and durability.

Characteristics

1.High Strength and Flexibility

Geomembranes possess high tensile strength and elongation at break, enabling them to adapt to uneven settlement and deformation of the foundation without easily rupturing.

2.Wide Temperature Range

Geomembranes can be used in environmental temperatures ranging from -70°C to 110°C, making them suitable for projects in extreme climatic conditions.

3.Strong UV Resistance

Geomembranes are treated with UV stabilizers on their surfaces, enabling them to effectively resist ultraviolet radiation and extend their outdoor service life.

4.High Adaptability

Geomembranes can be customized in terms of thickness, color, and specifications according to project requirements, making them applicable to various complex terrains and construction conditions.

5.Easy Detection and Repair

After installation, geomembranes can be quickly inspected for damage points using methods such as spark testing, facilitating timely repairs and ensuring effective seepage prevention.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

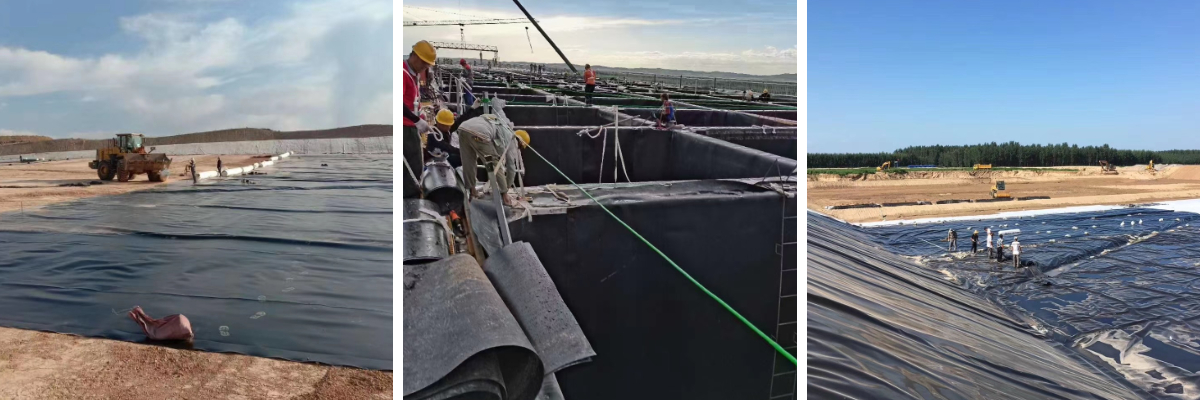

1.Water Conservancy Engineering

Geomembranes are used for anti-seepage treatment in reservoirs, dikes/dams, canals, sluice gates, and other water-related projects to prevent water leakage and ensure the safe utilization of water resources.

2.Environmental Engineering

Geomembranes serve as impermeable liners in landfills, wastewater treatment plants, hazardous waste disposal sites, and similar projects to prevent harmful substances from contaminating soil and groundwater.

3.Transportation Engineering

Geomembranes are applied in soft foundation treatment, slope protection, and tunnel waterproofing for highways, railways, airports, and other transportation projects to enhance structural stability and durability.

4.Mining Engineering

Geomembranes are utilized for anti-seepage and isolation in mines, tailings ponds, heap leach pads, and related facilities to prevent mineral liquid leakage and environmental pollution.

5.Agricultural Engineering

Geomembranes are employed for anti-seepage treatment in artificial lakes, aquaculture ponds, irrigation canals, and other agricultural projects to improve water use efficiency and promote agricultural production.

6.Construction Engineering

Geomembranes are used for waterproofing and moisture-proofing in basements, rooftop gardens, swimming pools, and other building projects to protect structural integrity and extend service life.

7.Salt Industry Engineering

Geomembranes are applied in salt pans, brine pools, and related facilities for anti-seepage and evaporation control to enhance salt production efficiency.

With its anti-seepage, durability, and ease of construction, geomembranes have become an indispensable functional material in modern civil engineering. From environmental seepage control to agricultural and water conservancy projects, their applications continue to expand, providing efficient solutions for engineering safety and ecological protection.