Geotextile Fabric Bags

1.High strength:

It has high tensile strength and can withstand large external forces.

2.Corrosion resistance:

It can maintain stable performance in harsh environmental conditions and is not easily eroded by chemical substances.

3.Aging resistance:

By adding anti-aging agents and other additives, it can resist natural factors such as ultraviolet radiation and temperature changes, slow down the aging speed of materials, and enable geotextile bags to have a long service life.

Product Introduction:

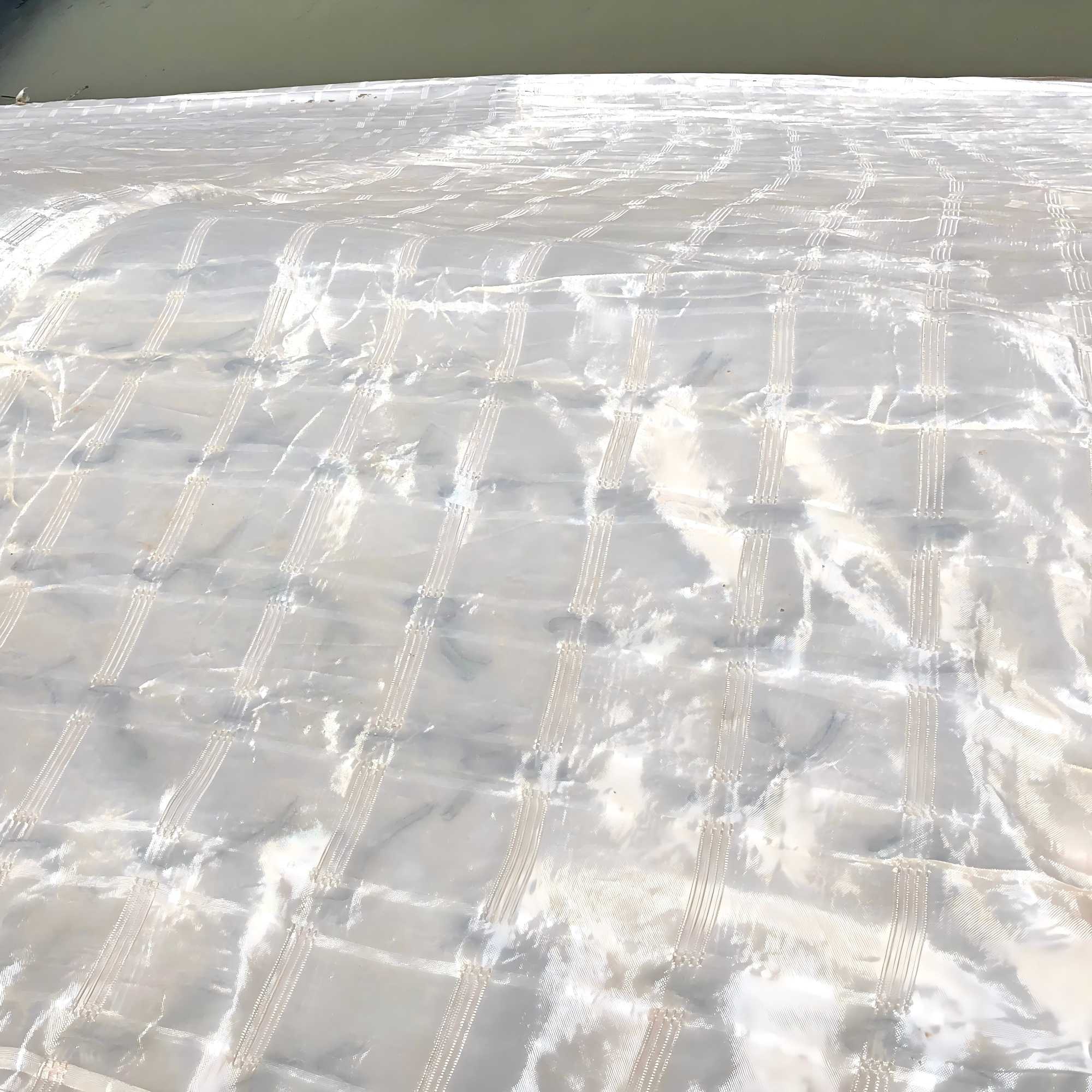

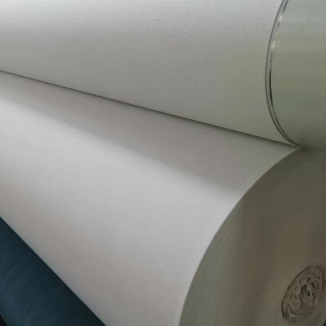

Geotextile Fabric Bags are a large-area continuous bag-like material fabricated from double layers of geotextile fabric. When filled with concrete or cement mortar and hardened, it forms an integrated concrete slab, making it particularly suitable for slope protection and similar engineering applications.

Material properties

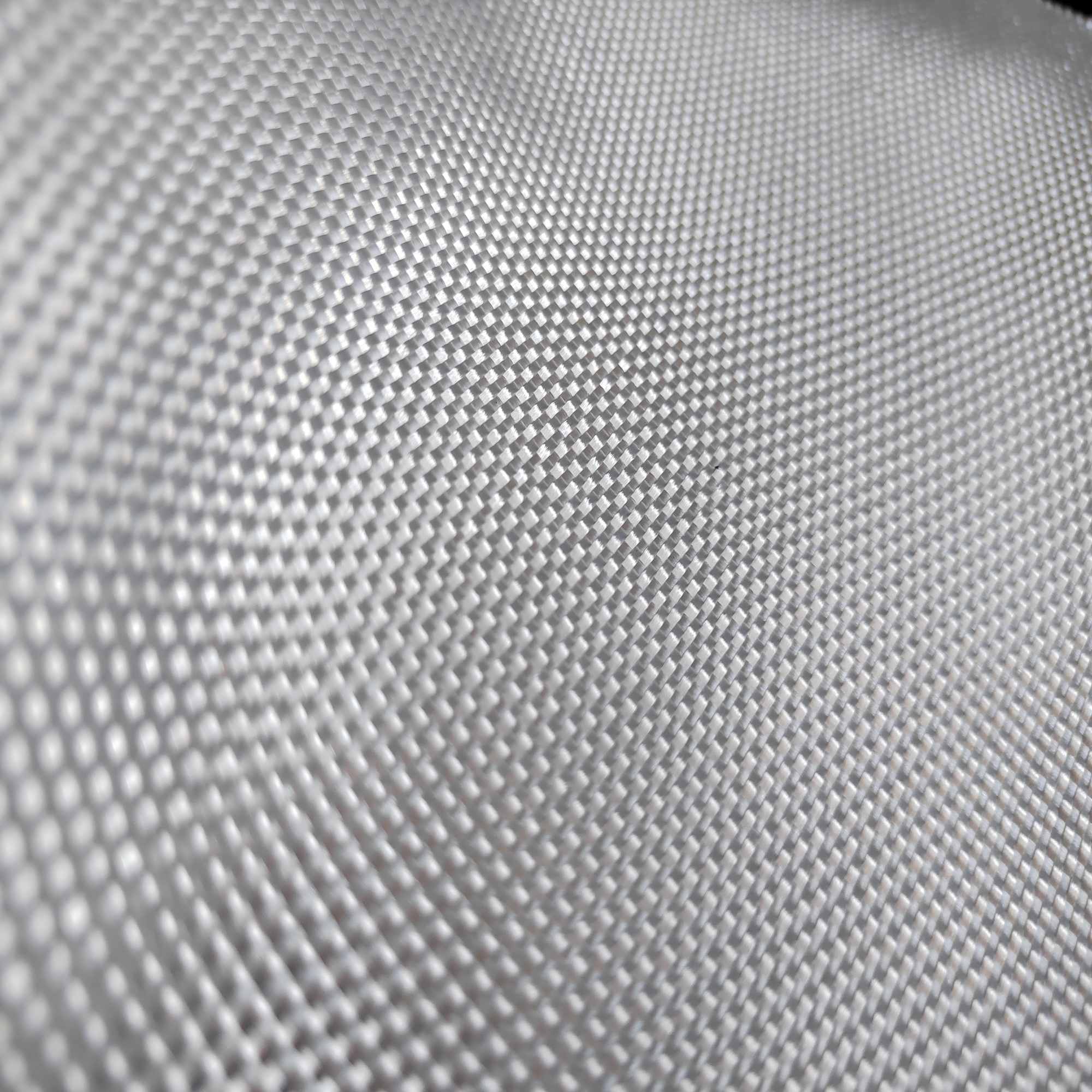

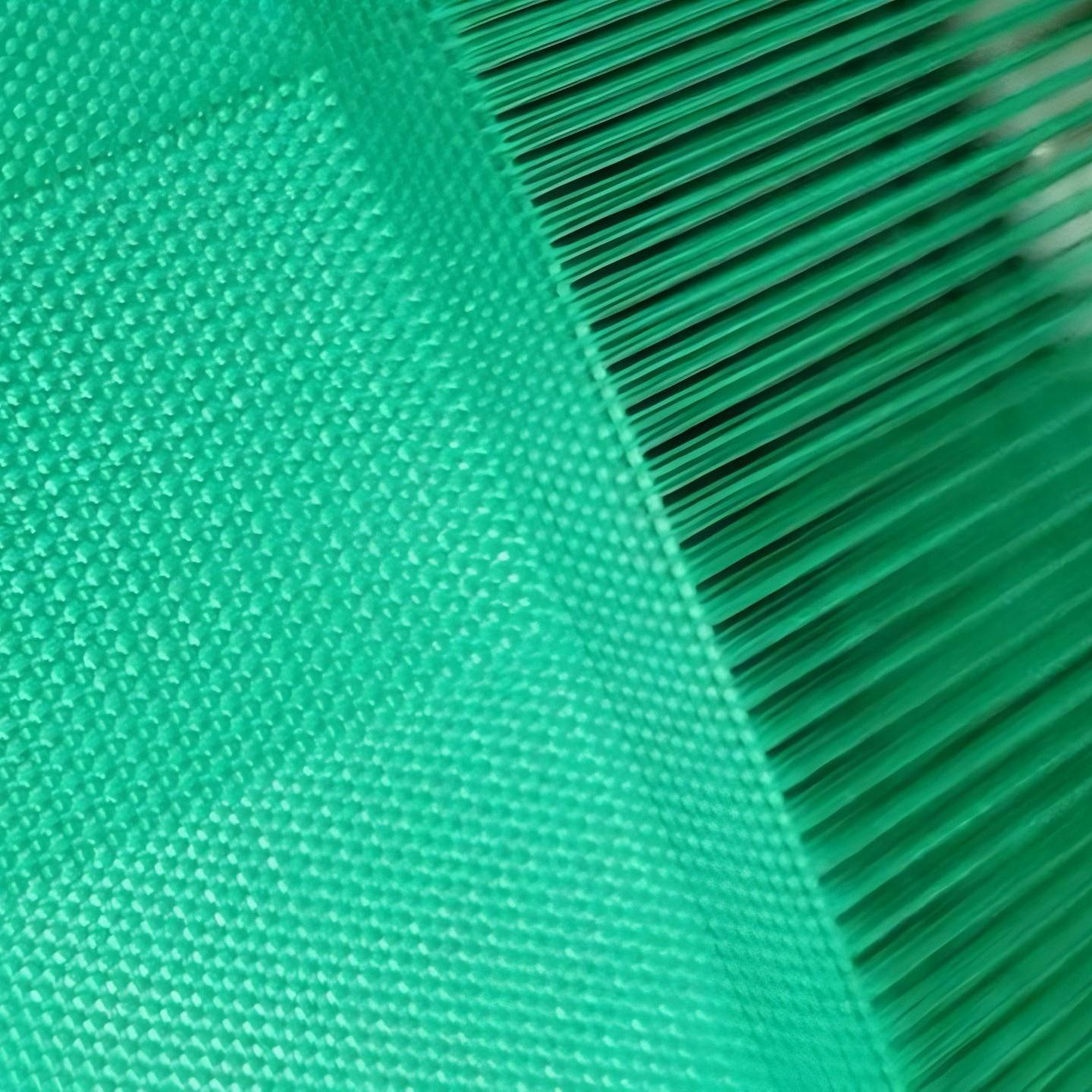

Main fabric: High-strength polypropylene (PP) or polyester (PET) woven fabric is used, with a tensile strength of 20 - 80kN/m. It is wear-resistant, corrosion-resistant, and has certain water permeability (able to drain the excess water during the concrete solidification process).

Structural design: Nylon ropes or chemical fiber ribs (referred to as "tensile bars") are set at certain intervals inside the bag body to control the expansion deformation during pouring and ensure a uniform thickness after molding (usually 5 - 30cm).

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

1.Hydraulic engineering: Mainly used for protective projects such as dike slope protection, revetment, ports, and docks in rivers, lakes, and seas. It can effectively prevent the damage of water flow scouring and wave erosion to the dikes, and enhance the stability and anti-scouring ability of the dikes.

2.Transportation engineering: Applied to slope protection of highway and railway subgrades to prevent soil erosion and slope collapse, improve subgrade stability, and ensure the safe operation of roads and railways.

3.Environmental protection engineering: Used to cover garbage in landfills to prevent garbage leakage from polluting groundwater and soil; it can also be used for anti-seepage treatment of sewage treatment ponds, oxidation ponds, etc., to prevent sewage leakage from polluting the surrounding environment.

4.Coastal protection engineering: Plays a protective role for beaches, seawalls, etc. on the coastline, resists the erosion of waves and storm surges, and protects the coastal ecological environment and the safety of coastal buildings.

The core performance of geofabriform lies in combining flexible laying ability with rigid protective strength, and it also has the characteristics of high - efficiency construction, strong terrain adaptability, and eco - friendliness. It is especially suitable for scenarios in projects such as water conservancy, coastal areas, and slopes, where there are high requirements for durability, erosion resistance, and environmental adaptability. Its performance parameters can be further optimized through material formulations (such as anti - UV fabrics, high - performance concrete) and structural designs (densifying tensile bars, strengthening joints) to meet the special needs of different projects (such as deep - sea protection, high - flow - velocity river treatment).