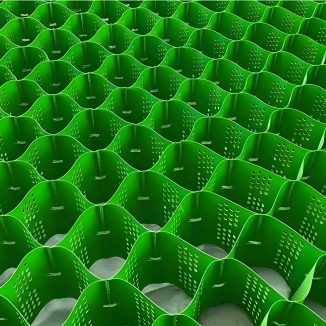

High Density Polyethylene HDPE Liners

1.Outstanding Impermeability:Effectively blocks the penetration of water, liquids and gases, adapting to complex environments.

2.Strong Weather Resistance:Resistant to UV rays and aging, maintaining long-term stability in harsh conditions.

3.Reliable Mechanical Properties:High tensile and tear strength, capable of withstanding construction forces and foundation deformation.

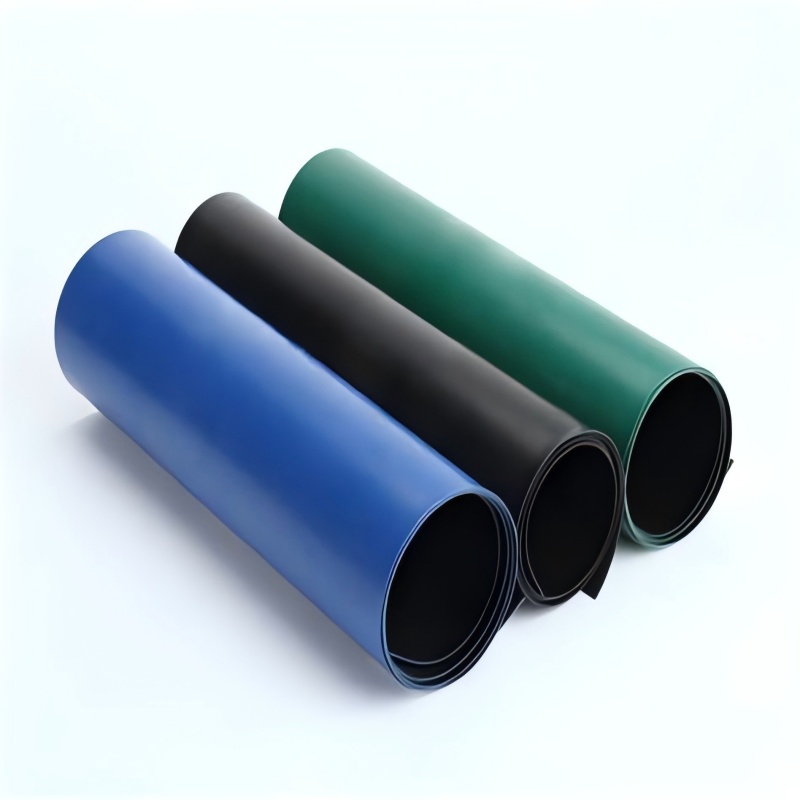

4.Convenient Construction:Lightweight and flexible, enabling efficient laying and connection, which can shorten the construction period.

5.Chemical Corrosion Resistance:Good stability, adapting to complex chemical environments.

6.Low Comprehensive Cost:Long service life and low maintenance costs, with excellent long-term economy.

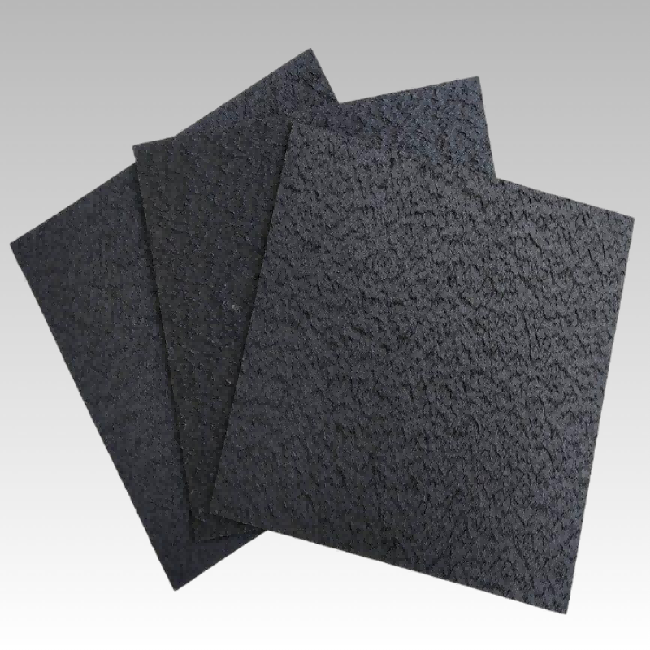

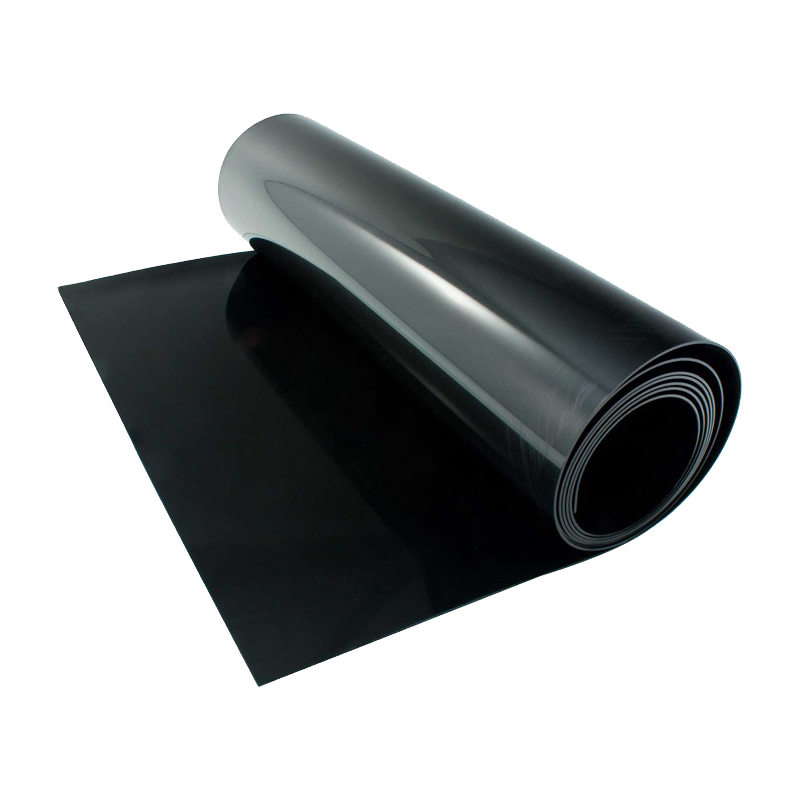

Product Introduction

High Density Polyethylene HDPE Liners is a flexible anti-seepage material made from polymer materials such as polyethylene and polypropylene through special processing techniques. Its dense molecular structure enables it to effectively block the penetration of water, various liquids and gases, and can maintain stable anti-seepage effects even under complex geological conditions.

In application scenarios, its role is particularly crucial: in water conservancy projects, it can be used for anti-seepage treatment of reservoirs and dams to prevent water leakage; in the environmental protection field, landfills use it to block the penetration of pollutants and protect soil and groundwater; in municipal projects such as artificial lakes and landscape pools, it can prevent water seepage, maintain stable water levels, and also has the function of isolating different media.

In addition, geomembrane also has weather-resistant properties such as UV resistance and anti-aging, and can adapt to harsh environments such as alternating high and low temperatures and direct sunlight. It has excellent mechanical properties, with high tensile and tear strength, and can withstand external forces during construction and foundation settlement deformation. Moreover, it is lightweight and flexible, and the laying and connection methods such as welding and gluing are simple, which can improve construction efficiency. Therefore, it is favored in various projects.

Product Parameters

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

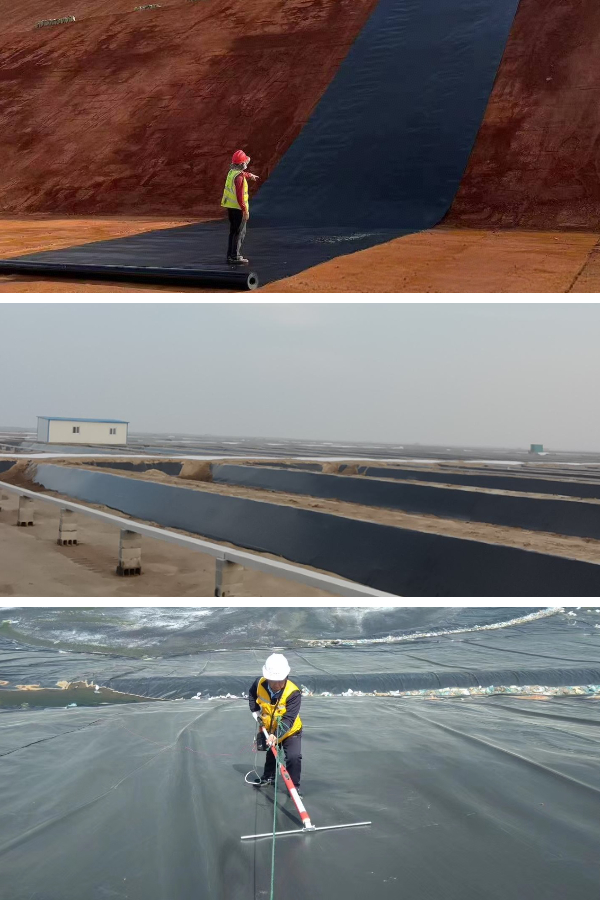

Product Application

With its excellent anti-seepage and isolation properties, geomembrane plays an irreplaceable key role in various fields such as water conservancy, environmental protection, and municipal administration. It provides a solid guarantee for the safe and stable operation of various projects and is an indispensable important material in modern engineering construction.

In water conservancy projects, it is the "anti-seepage barrier" for core facilities such as reservoirs and dams. Whether it is the bottom of large reservoirs, the slopes of dam bodies, or the anti-seepage treatment of small and medium-sized dams, laying geomembrane can effectively block the seepage path of water, significantly reduce the loss of water resources due to leakage, ensure that reservoirs can store water stably to meet the needs of irrigation, power generation, urban water supply, etc. At the same time, it can also enhance the anti-seepage capacity of dams, reduce the risks of piping and dam failure, and ensure the long-term safety of water conservancy projects.

In the field of environmental protection, geomembrane is a "protective shield" for the ecological environment. In the construction of landfills, geomembrane is laid over a large area from the bottom of the landfill area to the surrounding slopes, forming a complete anti-seepage system. This "protective shield" can firmly block the leachate generated during the degradation of garbage, prevent it from seeping into the soil and groundwater, avoid problems such as soil pollution and groundwater deterioration, build a solid defense line for the surrounding ecological environment, and help maintain ecological balance and sustainable development.

In municipal projects, the application of geomembrane makes various facilities more efficient and stable. In landscape projects such as artificial lakes and landscape pools, it can accurately prevent water from seeping into the ground, ensure the stable water level of the lake and pool surfaces, and maintain the beauty and integrity of the landscape. In facilities such as sedimentation tanks and reaction tanks of sewage treatment plants, it can not only prevent sewage leakage from polluting the surrounding environment but also avoid the mixing of sewage at different stages during the treatment process through isolation, improve the efficiency and quality of sewage treatment, and make municipal facilities better serve urban operation.

In short, the wide application of geomembrane in water conservancy, environmental protection, municipal and other fields not only specifically solves the anti-seepage and isolation problems in engineering but also contributes significantly to ensuring project quality, saving resources, and protecting the ecological environment. Its importance is increasingly prominent in various engineering constructions.