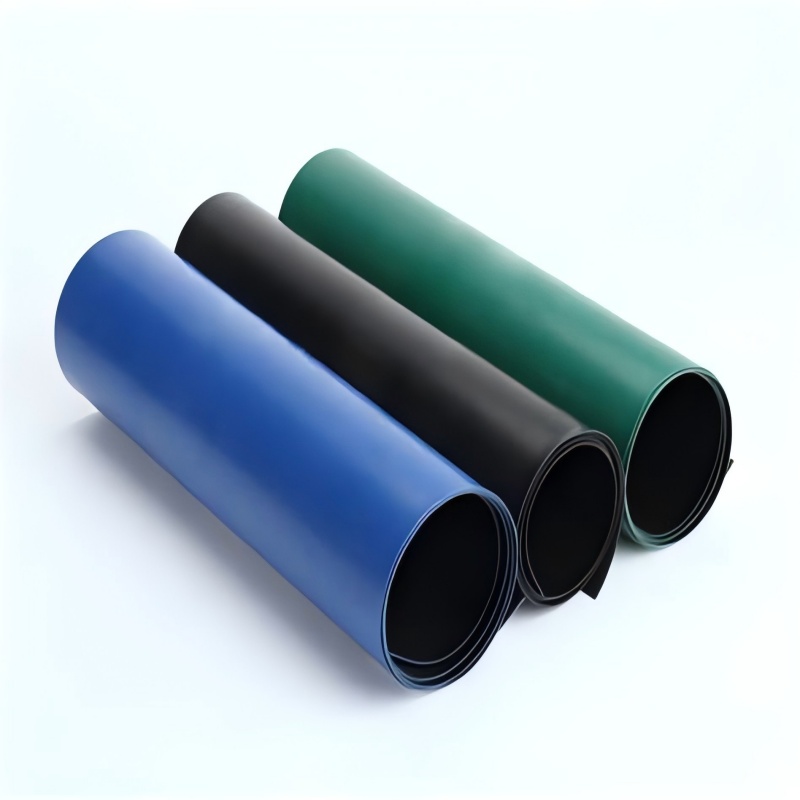

60 mil HDPE Liner

1. Excellent anti-seepage performance

The permeability coefficient is extremely low, almost impermeable and non breathable, effectively preventing the migration of pollutants, suitable for environmental protection and hydraulic anti-seepage scenarios.

2. Chemical corrosion resistance

Especially HDPE material can resist the erosion of strong acids, alkalis, salts, oils and other chemical substances, making it suitable for harsh environments such as landfills and chemical parks.

3. High strength and durability

Strong tensile, tear resistant, and puncture resistant abilities, not easily aged after long-term use

4. Lightweight and efficient construction

Lightweight, easy to transport and lay, construction speed much faster than traditional concrete anti-seepage, greatly shortening the construction period.

Product Introduction:

60 mil HDPE Liner is a waterproof and barrier material made from polymer materials such as polyethylene (PE), polyvinyl chloride (PVC), ethylene/vinyl acetate copolymer (EVA), etc. It is mainly used to prevent water, liquid, or gas from penetrating.

Core performance characteristics

1. Excellent anti-seepage performance:

The water vapor permeability coefficient is as low as 1 × 10 ⁻¹³ g · cm/(cm ² · s · Pa), which can effectively block liquid permeation.

2. Chemical corrosion resistance:

Resistant to over 80 types of chemical media such as acid, alkali, and salt corrosion, suitable for scenarios such as chemical wastewater tanks and tailings ponds.

3. Strong environmental adaptability:

Wide temperature range and excellent frost resistance. Resistant to UV aging, with a lifespan of over 50 years when used in the dark.

4. Outstanding mechanical performance:

Tensile strength ≥ 12MPa, elongation at break ≥ 300%, able to adapt to foundation deformation.

High puncture resistance, able to resist sharp objects such as gravel and tree roots.

5. Construction convenience:

The width can reach 6 meters, reducing the number of welds and lowering the risk of leakage.

Support hot melt welding, with weld strength higher than the base material, ensuring overall sealing.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

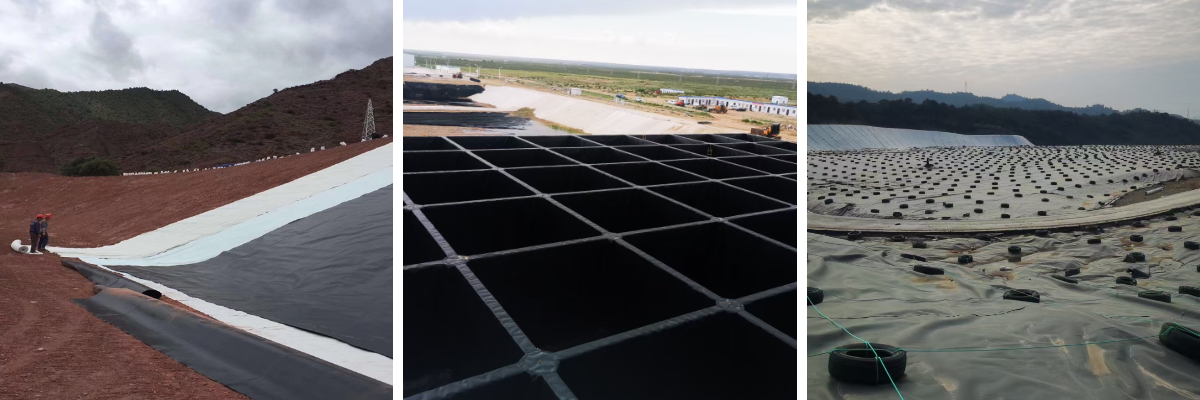

Product Applications:

1. Water conservancy engineering:

The anti-seepage lining of reservoirs, dams, and water channels prevents water leakage and soil erosion.

2. Environmental engineering:

The bottom and side walls of the landfill site are impermeable to prevent leachate from polluting groundwater.

Sewage treatment plant regulating pool and industrial waste treatment plant anti-seepage.

3. Municipal engineering:

Waterproofing for subways, tunnels, and underground buildings, as well as moisture prevention for roof gardens and planted roofs.

4. Agriculture and Aquaculture:

Fish ponds, shrimp ponds, and sea cucumber enclosures are protected by slope protection to prevent seepage and reduce aquaculture costs.

Irrigation system, reservoir anti-seepage, improve water resource utilization efficiency.

5. Mining and Petrochemicals:

Tailings pond, heap leaching tank, and washing tank are anti-seepage to prevent harmful substances from penetrating.

Oil storage tanks and chemical reaction tanks are lined to prevent chemical leaks.

6. Transportation facilities:

Strengthening the foundation of highways and railways, preventing seepage in culverts, and extending the service life of roads.

Geomembranes have become the preferred alternative to traditional anti-seepage materials in modern engineering due to their core advantages of high efficiency, strong durability, convenient construction, and low cost. It has strong adaptability and diverse functions, and is widely used in fields such as water conservancy, environmental protection, transportation, agriculture, etc., providing reliable guarantees for engineering safety and sustainable development.