Geotextile for Slope Protection

1. High strength: It has good tensile and tear resistance, and can enhance soil stability.

2. Permeability: Allow water to pass through while effectively preventing soil particle loss and clogging.

3. Corrosion resistance: resistant to chemical corrosion, acid and alkali, suitable for various complex environments.

4. Convenient construction: lightweight, easy to cut, simple to lay, can significantly reduce project costs.

5. Environmental friendliness: Some materials can be recycled to reduce their impact on the environment.

Product Introduction:

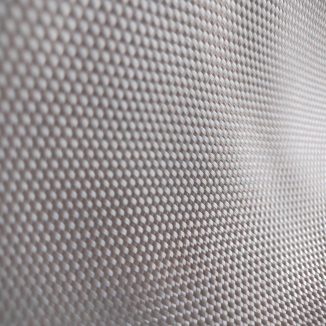

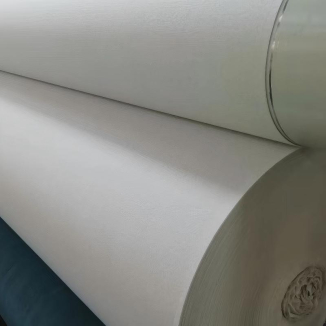

Geotextile for Slope Protection is a permeable geosynthetic material made from synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. The finished product is in the form of a cloth, with a width of up to 4-9 meters and a length of 50-100 meters. Its core function is to achieve permeability through the gaps between fibers, while blocking the loss of soil particles, forming a physical barrier of "permeable but impermeable soil". According to different processes, it can be divided into woven geotextiles and needle punched non-woven geotextiles. The former has higher strength, while the latter has better filtration performance.

characteristic

1. Multifunctionality: It can simultaneously achieve multiple functions such as filtering, drainage, isolation, reinforcement, etc., to meet the needs of different engineering scenarios.

2. Good flexibility: It can fit well with irregular terrain or structural surfaces, reducing damage caused by deformation.

3. Controllable permeability: By adjusting the fiber density and process, different permeability rates can be designed to meet the control requirements of specific projects for water flow.

4. Environmental friendliness: Most geotextiles are made of recyclable polymer materials and have minimal environmental disturbance during construction, which is in line with the concept of green engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Dam protection: As a filter layer and drainage layer, it prevents infiltration damage. For example, the Three Gorges Dam uses geotextiles to reinforce the dam body, reducing leakage by up to 50%.

Channel lining: Lay geotextile at the bottom of the channel to reduce water leakage and improve water delivery efficiency by more than 20%.

2. Transportation Engineering

Road base: Isolate aggregates of different particle sizes to prevent mixing and improve road surface smoothness. After the use of geotextile reinforcement on the Beijing Shanghai Expressway, the cracks on the road surface were reduced by 40%.

Railway track bed: Drainage isolation to prevent ballast from being embedded in the roadbed and extend the service life of the track. The Qinghai Tibet Railway has laid geotextiles in permafrost areas to effectively solve the problem of frost heave.

3. Environmental Protection Engineering

Landfill site: Composite with geomembrane to form an anti-seepage system, blocking leachate pollution. After using geotextiles at the Beijing Asuwei landfill site, the risk of groundwater pollution has been reduced by 90%.

Wastewater treatment: As a biological filter material, it improves treatment efficiency. After using geotextile, the effluent quality of Shanghai Bailonggang Sewage Treatment Plant meets the Grade A standard.

4. Construction and Underground Engineering

Basement waterproofing: In combination with waterproof coatings and rolls, enhance tear resistance. After the basement of Shenzhen Ping An Financial Center was reinforced with geotextile, the leakage rate decreased to below 0.5%.

Roof waterproofing: As a reinforcement layer, it improves the waterproof layer's puncture resistance. After using geotextile on the roof of the National Stadium "Bird's Nest", the waterproof life has been extended to 30 years.

5. Municipal and Landscape Engineering

Slope protection: prevent rainwater erosion and reduce soil erosion. After laying geotextile on the slope of Xixi Wetland in Hangzhou, the vegetation coverage rate increased to 95%.

Greening planting: Fixed planting soil, water retention and promotion of growth. After using geotextile in Beijing Olympic Forest Park, the plant survival rate increased to 98%.

6. Mining and Ocean Engineering

Tailings dam protection: As an initial dam surface filter layer, it prevents tailings loss. After using geotextile for the tailings dam of Dexing Copper Mine in Jiangxi, the stability of the dam body has been significantly improved.

Coastal protection: resist wave erosion and protect the coastline. After using geotextile for the breakwater of Dongjiakou Port in Qingdao, maintenance costs have been reduced by 60%.

7. Agricultural Engineering

Farmland drainage: Improve soil permeability and promote crop growth. After adopting geotextiles in the Northeast Black Soil Protection Project, grain production increased by 15%.

Aquaculture: As a bottom anti-seepage layer to prevent water pollution. After using geotextile in the Yangcheng Lake hairy crab breeding base in Jiangsu, the survival rate of crab seedlings increased by 20%.

8. Emergency and Temporary Engineering

Flood prevention and rescue: Quickly lay temporary water barriers to control dangerous situations. In the rainstorm in Henan Province in 2021, geotextiles are widely used to strengthen dams, reducing economic losses by more than 1 billion yuan.

Temporary road: Lay geotextile on soft soil foundation to enhance bearing capacity. After the temporary roads for the Winter Olympics were reinforced with geotextile, the efficiency of vehicle traffic increased by three times.

Geotextile, with its excellent performance and wide applicability, has become an indispensable key material in modern civil engineering, playing an important role in improving engineering quality, reducing costs, and protecting the ecological environment.