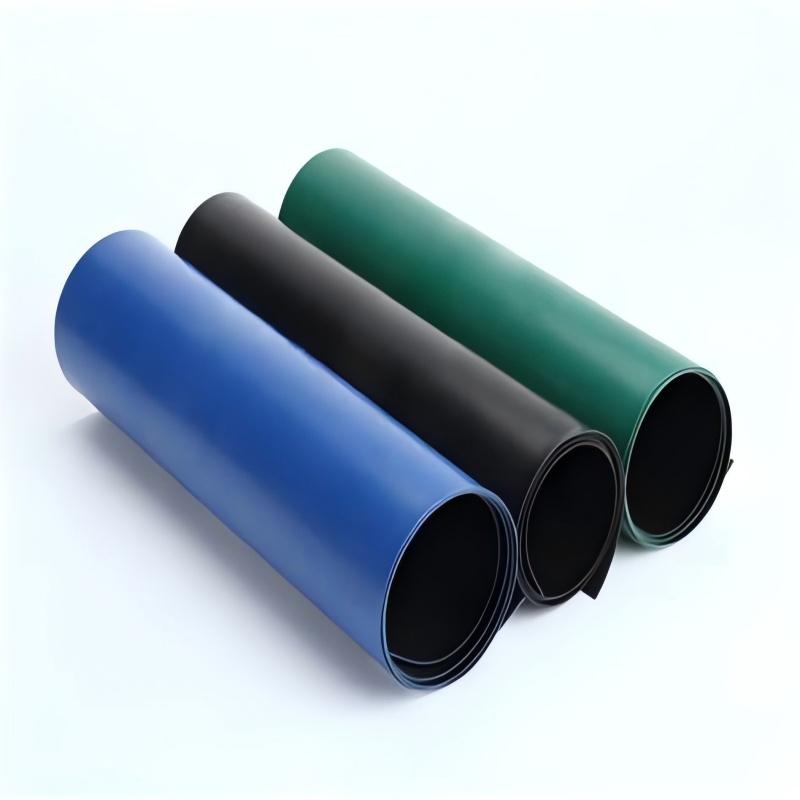

HDPE Membrane Sheet

1.Exceptional Impermeability Performance

The permeability coefficient is ≤10⁻¹¹ cm/s (1,000 times lower than clay), effectively preventing liquid leakage.

2.Strong Chemical Resistance

Resistant to corrosion, acids, alkalis, salts, oil, and other chemical substances, ensuring a long service life.

3.High Strength and Durability

Capable of withstanding foundation settlement and soil pressure, avoiding cracking.

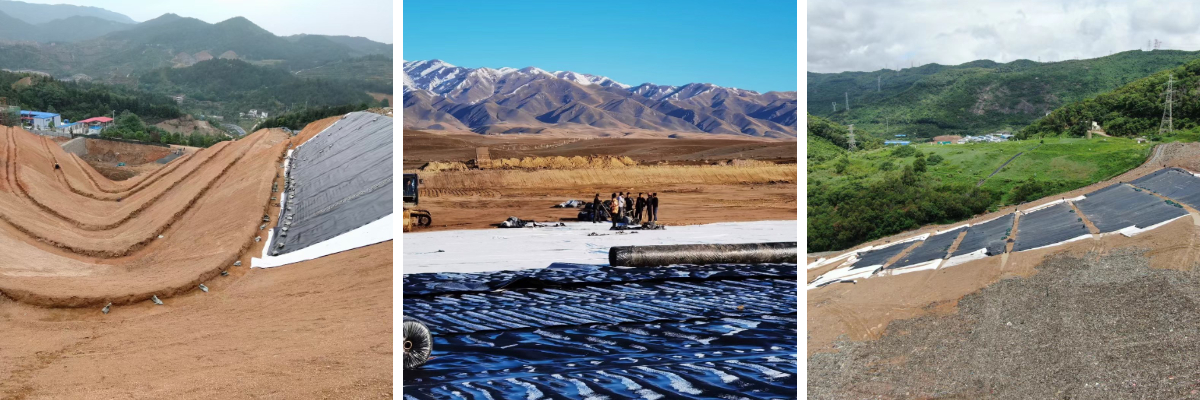

4.Convenient and Efficient Construction

Lightweight for easy manual handling, reducing construction difficulty. High flexibility allows it to conform to curved surfaces and slopes, minimizing splicing challenges.

Product Introduction:

HDPE Membrane Sheet is manufactured using plastic films (such as polyethylene, polyvinyl chloride, etc.) as impermeable base materials, processed through specialized techniques.

Product Characteristics

1.Excellent Impermeability:

The geomembrane’s permeability coefficient can reach as low as 10⁻¹¹ cm/s, effectively preventing liquid penetration.

2.Superior Chemical Resistance:

Resistant to corrosion from acids, alkalis, salts, and other chemicals, making it suitable for harsh environments.

3.High Mechanical Strength:

Features high tensile strength and elongation, enabling it to withstand external forces and deformation.

4.Strong Aging Resistance:

With the addition of anti-aging agents, the service life exceeds 50 years.

5.Convenient Construction:

Lightweight and highly flexible, facilitating easy transportation, handling, and installation.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1.Environmental Engineering:

Landfills, wastewater treatment plants, hazardous waste disposal sites, etc.

2.Water Conservancy Engineering:

Reservoirs, dams, canals, water storage ponds, artificial lakes, etc.

3.Transportation Engineering:

Foundation seepage control for highways, railways, and airport runways.

4.Mining Engineering:

Tailings ponds, heap leach pads, ore washing ponds, etc.

5.Agricultural Engineering:

Aquaculture ponds, water storage ponds, irrigation channels, etc.

6.Construction Engineering:

Basements, rooftop gardens, swimming pools, etc.