Geo Tech Cloth

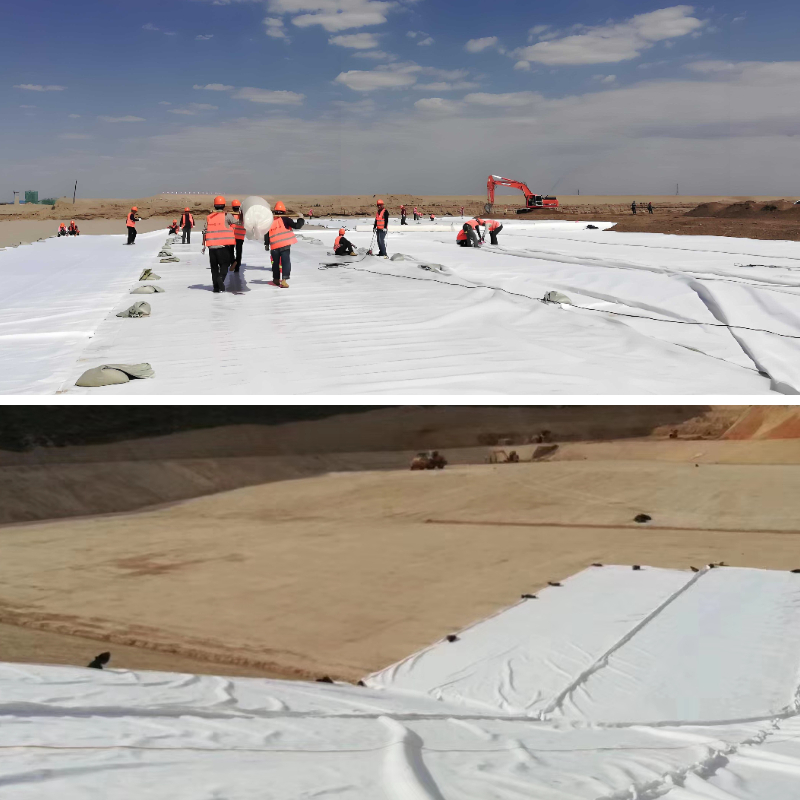

1. Convenient construction: lightweight, easy to cut and lay, improving project efficiency.

2. Economically efficient: Compared to traditional materials such as sand and concrete, it has lower costs and better results.

3. Environmental protection and energy conservation: Reduce the use of natural materials and minimize the environmental damage caused by engineering projects.

4. Multifunctionality: Different types (such as weaving, non-woven fabric) can be selected according to needs to meet different engineering requirements.

Product Introduction:

Geo Tech Cloth is a permeable geosynthetic material made of synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. The finished product is in the form of a cloth, with a width of up to 9 meters and a unit area mass of 100-1000g/m ². Its core structure is formed by interweaving fibers to create pores, giving the material a balance between permeability and mechanical properties, becoming a "flexible bridge" connecting soil and structure in geotechnical engineering.

Core Features

1. High strength and durability

The tensile strength reaches 20-150kN/m, which can withstand complex stresses and long-term loads during construction. For example, in the reinforcement of high and steep slopes, the modulus advantage of PET geotextile makes it the preferred choice.

Resistant to UV aging, with a strength retention rate of ≥ 50% after 500 hours of xenon lamp aging test, ensuring a service life of more than 20 years for outdoor engineering.

2. Permeable filter

The vertical permeability coefficient is 0.1-10cm/s, allowing water flow to pass through while intercepting soil particles to prevent soil erosion.

3. Isolation and protection

Placed between crushed stone and soft soil to prevent a decrease in bearing capacity caused by material mixing. In the soft foundation treatment of the Beijing Shanghai high-speed railway, the geotextile isolation layer reduces the settlement of the roadbed by 30%.

4. Reinforcement dispersion

By providing additional tensile strength through friction, the overall stability of the soil is improved. In reinforced earth retaining walls, geotextiles can disperse loads and reduce uneven settlement by more than 50%.

5. Corrosion and Microbial Resistance

Long term service in acidic and alkaline environments with pH values of 2-12, and not affected by insect infestation, suitable for harsh environments such as landfills.

6. Convenient construction

The material is gentle and can be manually or mechanically laid, greatly reducing the construction period.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Dam protection: As an anti filter layer, it prevents damage caused by piping. In the Three Gorges Project, the coverage area of geotextile exceeds 2 million square meters, effectively intercepting soil particles with a particle size of ≥ 0.1mm.

Channel anti-seepage: Composite with geomembrane to form a "one cloth, one membrane" structure, reducing leakage by more than 90%.

2. Transportation infrastructure

Roadbed reinforcement: Laying geotextile in soft soil foundation can increase the bearing capacity by 2-3 times. In the soft foundation treatment of a certain section of the Shanghai Kunming high-speed railway, geotextile reinforcement was used to control the post construction settlement within 10cm.

Road maintenance: As an anti cracking material for asphalt pavement, it delays the occurrence of reflective cracks. Experiments have shown that geotextile interlayers can extend the lifespan of road surfaces by 5-8 years.

3. Environmental Protection Engineering

Landfill site: serves as a cushion protective layer to prevent leachate from contaminating groundwater. The Beijing Asuwei landfill site adopts a composite structure of geotextile/geomembrane, which reduces the leakage of leachate to below 0.01L/㎡· d.

Wastewater treatment: used for the biofilter filter layer to improve treatment efficiency by 30%.

4. Municipal construction

Underground structure waterproofing: In tunnel and basement engineering, geotextile protects the geomembrane from puncture damage, ensuring the integrity of the waterproof layer.

Pipeline protection: Wrap drainage pipes to reduce damage caused by soil friction and extend their service life by more than 15 years.

5. Emerging scenarios

Ecological restoration: As a filter layer in artificial wetlands, it maintains water exchange efficiency while preventing substrate loss.

Agricultural engineering: used for farmland drainage, lowering groundwater levels, and preventing soil salinization.

Geotextile solves the problem of "large-scale engineering" with "small materials", and its multifunctionality, durability, and environmental advantages make it the "invisible backbone" of modern infrastructure construction. From the Three Gorges Dam to the Hong Kong Zhuhai Macao Bridge, from the Qinghai Tibet Railway to urban subways, geotextiles are continuously expanding their application boundaries through technological innovation, providing solid support for sustainable development.