Reinforced Geotextile

1.It has multiple functions such as reinforcement, separation, and filtration, and can be flexibly applied according to engineering requirements.

2.It has stable chemical properties, is not easily corroded by microorganisms, and has a long service life.

3.It has good bonding with the soil, can deform with the soil without being damaged, and reduces construction difficulty.

4.It has a strong ability to disperse loads, uniformly transfers stress, and reduces the risk of foundation settlement.

5.Resistant to acid and alkali, anti-ultraviolet aging, suitable for long-term outdoor use (such as exposure to soil, water, and climate erosion environment).

6.High tensile strength and tear resistance can effectively enhance the tensile and shear strength of soil and inhibit deformation.

Product Introduction:

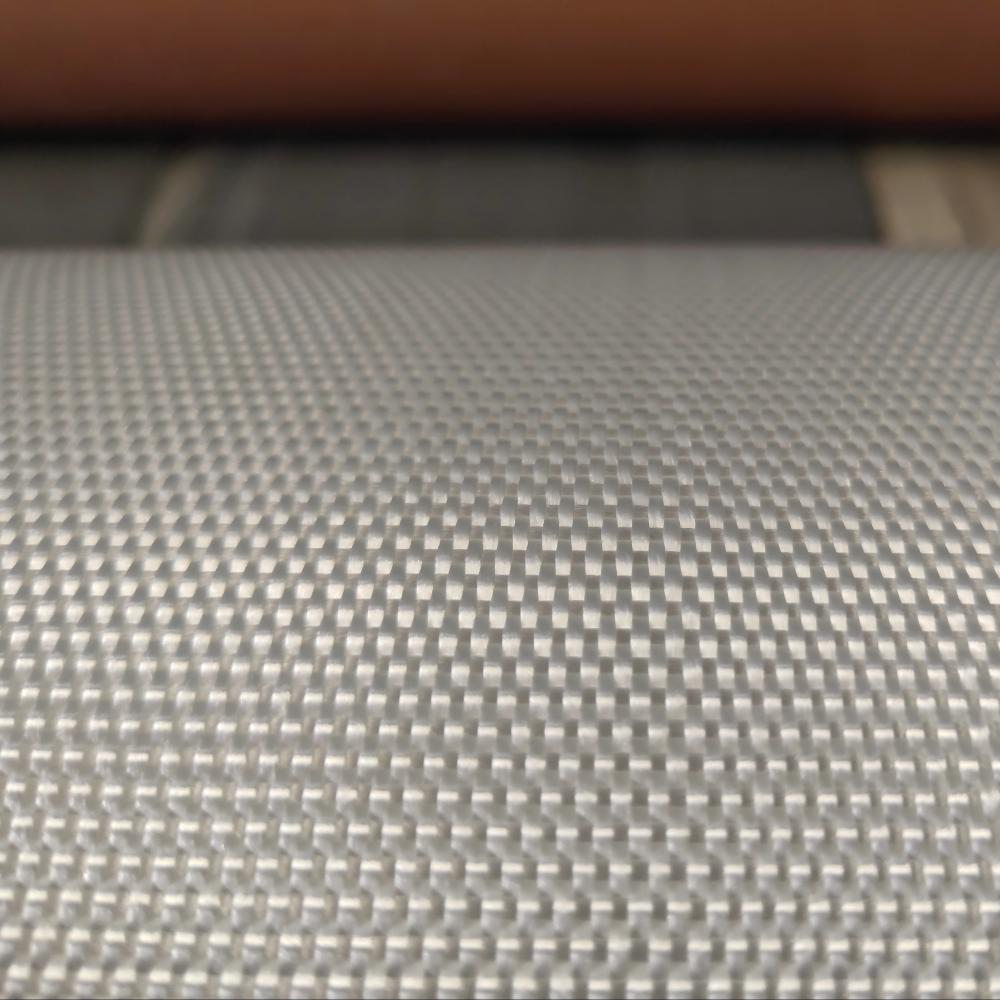

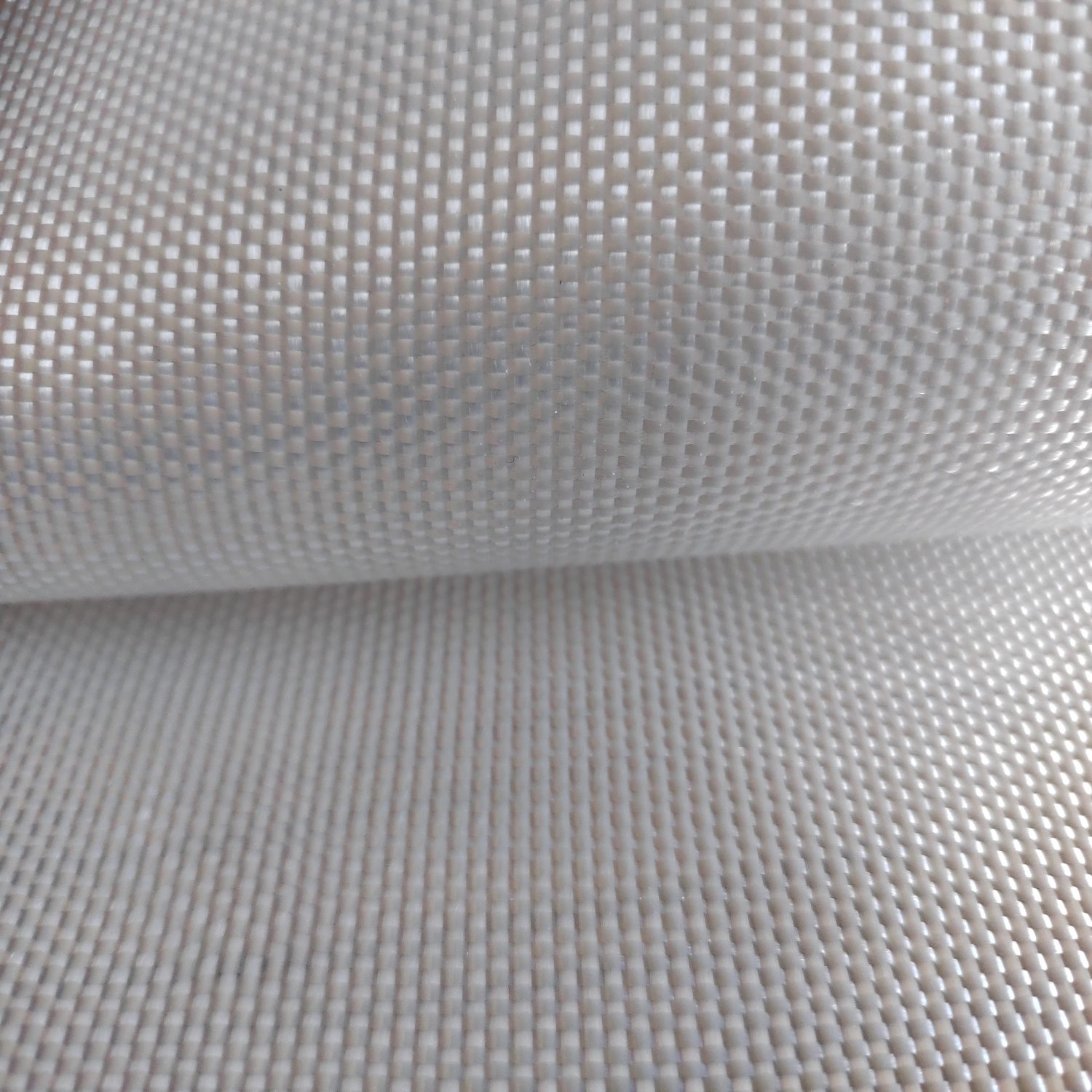

Reinforced Geotextile is a kind of geotextile mainly made from synthetic fiber filaments such as polypropylene (PP), polyester (PET), and polyamide (PA). The filaments are produced by the melt - spinning method or the solution - spinning method, and then the geotextile is woven through the weaving process.Filament woven geotextile is a kind of geotextile mainly made from synthetic fiber filaments such as polypropylene (PP), polyester (PET), and polyamide (PA). The filaments are produced by the melt - spinning method or the solution - spinning method, and then the geotextile is woven through the weaving process.

High strength:

Using high-strength industrial synthetic fibers as raw materials, it has relatively high original strength. After weaving, a regular interwoven structure is formed, and the mechanical strengths such as tensile, tear, burst, and puncture resistance are further improved. It is more than twice the strength of short-fiber geotextiles of the same gram weight. In particular, the burst and puncture resistance strengths reach over 2200 Newtons.

High durability:

Synthetic chemical fibers are not prone to deformation, decomposition, or weathering. They can maintain their original properties for a long time, and to a certain extent, effectively extend the lifespan of the project.

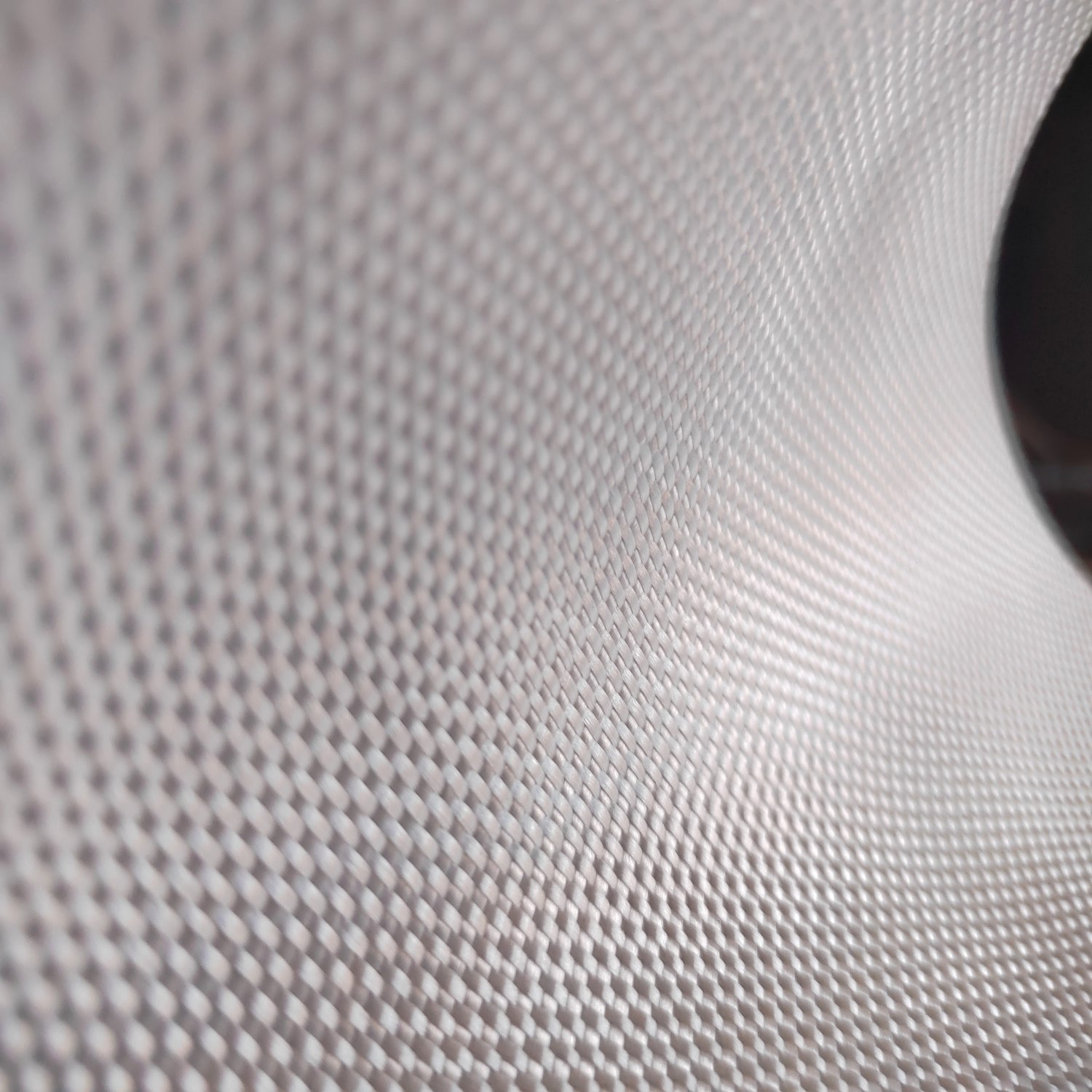

Good water permeability:

The void structure generated by the weaving process is uniform, and its structural pores can be effectively controlled to achieve a certain degree of water permeability. It can play a good anti-filtration role in the project, allowing water to pass through while effectively intercepting soil particles, fine sand, small stones, etc.

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

Traffic engineering

Highway and railway subgrades

Reinforce soft soil foundations, disperse the stress of vehicle loads, and reduce subgrade settlement and cracks. Used at the joints of new and old subgrades to prevent pavement damage caused by uneven settlement.

Slopes and Retaining Walls

Enhance the anti - sliding stability of slope soil, suppress the landslide risk; be used as reinforcement material in reinforced soil retaining walls to reduce the lateral pressure of the wall.

Municipal and Construction Engineering

Foundation Treatment

Reinforcement of soft soil foundations (such as landfills, industrial park foundations), improve bearing capacity, and reduce settlement risks.

Parking Lots and Squares

Laying between the base layer and the surface layer to disperse vehicle loads and extend the service life of the road surface.

Environmental Protection and Mining Engineering

Landfill Sites

Reinforce the slopes of landfills to prevent landslides of garbage piles; serve as a reinforcing layer under the impermeable layer to enhance the overall structural stability.

Tailings Dams and Slag Yards

Improve the shear strength of tailings piles to prevent collapse and debris flows, and assist the operation of the drainage system at the same time.

Hydraulic Engineering

Dams and Riverbank Protection

Reinforce the slopes of dams to resist the scouring of water flow; prevent soil collapse during riverbank renovation and maintain the stability of the bank slopes.

Reservoir and Canal Seepage Prevention

Combine with seepage prevention materials (such as HDPE membranes) to enhance the tensile performance of the seepage prevention system and prevent cracking and leakage.

Special Engineering Scenarios

Airport Runway

Foundation: Disperse the takeoff and landing loads of aircraft, ensuring the flatness and safety of the runway.

Marine Engineering: Such as soft foundation reinforcement in land reclamation from the sea, or resisting the impact of ocean waves in coastal dike projects.

Reinforced Geotextile address the problem of insufficient soil stability in engineering through functions such as "stress transfer and dispersion, soil strength enhancement, and deformation suppression", and are particularly suitable for scenarios with heavy loads, easy deformation, or complex geological conditions.