Geotextiles in Road Construction

1. Enhance performance: effectively reinforce soil, disperse loads, improve engineering stability and bearing capacity.

2. Cost saving: Replace traditional sand and gravel materials, significantly reducing material, transportation, and labor costs.

3. Efficient construction: The material is lightweight and easy to lay, which can significantly shorten the construction period and improve construction efficiency.

4. Persistent filtration: It allows water to pass through while preventing soil erosion, ensuring the long-term reliability of the drainage system.

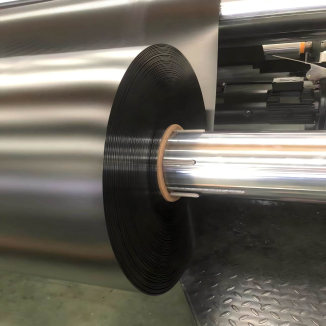

Product Introduction:

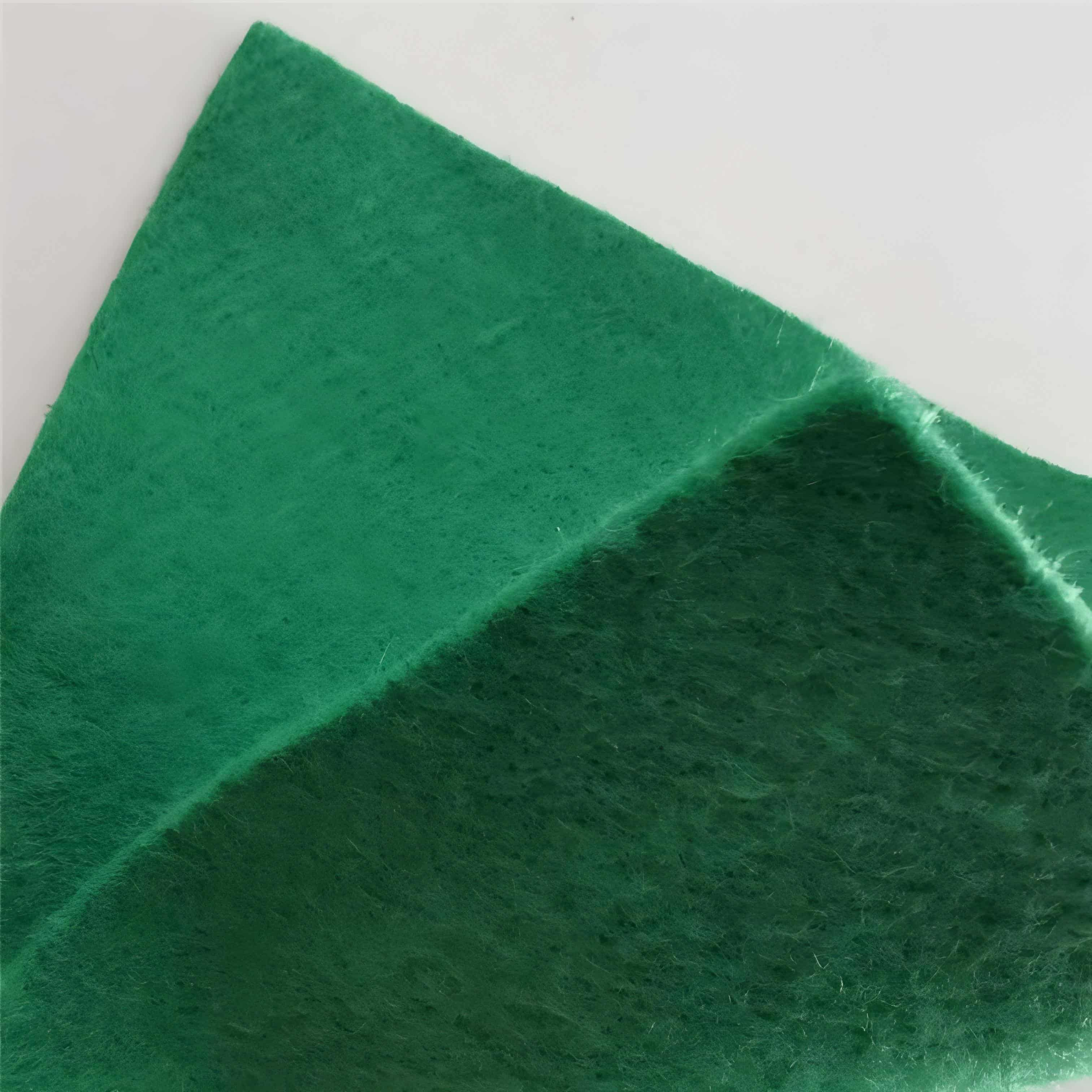

Geotextiles in Road Construction are new type of geotechnical material made from synthetic fibers (such as polyester, polypropylene, nylon, etc.) or natural fibers (such as cotton, hemp, etc., which are now less commonly used) as raw materials. It is a permeable geotechnical composite material made through processes such as needle punching, weaving, and hot melt bonding. It plays the role of an "engineering textile" in fields such as geotechnical engineering, water conservancy, and transportation. Its core function is to solve problems such as soil filtration, drainage, isolation, and reinforcement, and to enhance engineering stability and durability.

Core Definition

The essence of geotextile is a polymer fiber product with permeability, which needs to meet two key properties:

1. Material properties: synthetic fiber is the main raw material (accounting for more than 90%), and natural fiber is only used for temporary or low requirement projects due to poor corrosion resistance and aging resistance;

2. Functional attributes: Must have water permeability (different from impermeable materials such as geomembranes), and also need to adapt to the engineering's requirements for strength, filtration accuracy, weather resistance, etc;

3. Application scenarios: Only used in geotechnical engineering related fields (such as roadbeds, dams, landfills, etc.), with completely different uses and performance standards from ordinary textiles (such as clothing, home textile fabrics).

Core Features

The performance design of geotextile is completely based on engineering requirements, and its core features can be summarized as "five durability and one permeability+functional adaptation":

1. Excellent physical and mechanical properties

High strength: The tensile strength of synthetic fibers (such as polyester) can reach 20-50kN/m, which can withstand the tensile force generated by soil deformation and avoid engineering cracking;

Tear resistance/puncture resistance: The tear resistance strength of woven geotextile is significantly higher than that of needle punched fabric, which can resist the puncture of sharp objects such as stones and roots, and protect the engineering structure;

Good dimensional stability: low thermal shrinkage rate (usually<3%), not easily deformed in high and low temperature environments (-40 ℃~80 ℃), suitable for engineering in different climate regions.

2. Strong resistance to environmental erosion

Chemical corrosion resistance: It has good tolerance to acids and bases (such as acidic substances in soil and alkaline components in sewage), salts (such as seawater salts in coastal areas), and will not degrade due to chemical reactions;

Anti biological damage: It is not decomposed by microorganisms (such as bacteria and fungi), nor does it attract insects and mice to bite, avoiding damage to materials by biological activities;

Anti aging: after adding anti ultraviolet (UV) agent, it can be exposed to the sun for a long time without aging and embrittlement, and its service life can reach 10-50 years (adjusted according to the engineering level).

3. Controllable permeability and filtration

Permeability: The porosity is usually 60% -90%, and the permeability coefficient (k value) is between 10 ⁻³ -10 ⁻¹ cm/s. It can be adjusted according to engineering requirements (such as drainage speed and water retention requirements), which can quickly discharge excess water and avoid soil loss;

Filtration: By controlling the pore size (usually 0.05-0.5mm), it is possible to achieve "allowing water to pass through and preventing soil particle loss" - for example, in the anti-seepage layer of a dam, it can filter out sediment in seepage and prevent "piping" (soil being emptied by water flow) inside the dam.

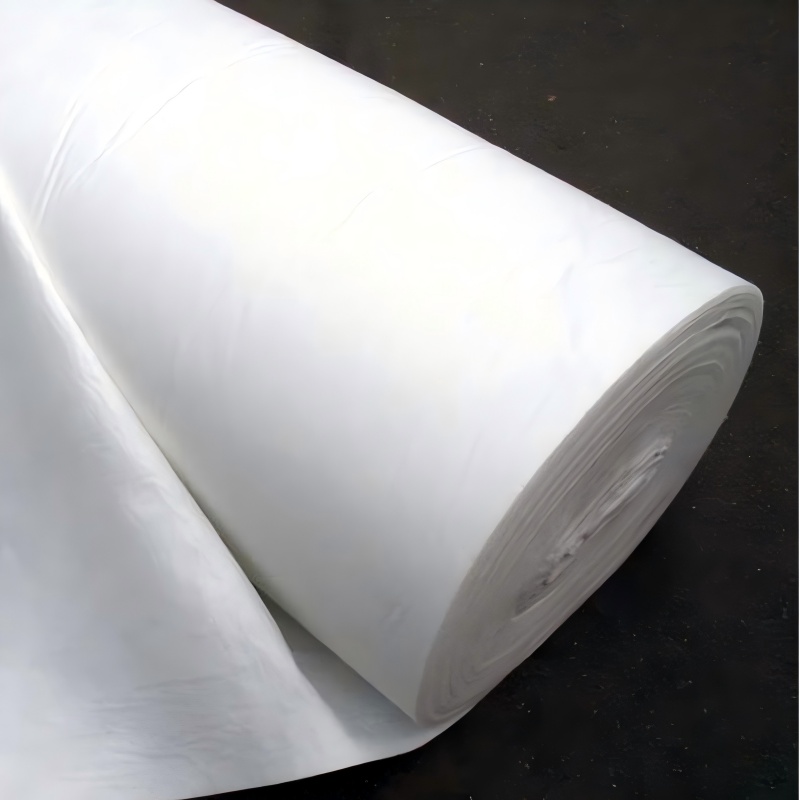

4. High construction convenience

Lightweight: The unit area mass is usually 100-600g/㎡, and the length of a single roll can reach 50-100m. It is easy to transport and lay without the need for heavy equipment;

Easy to splice: It can be spliced through methods such as hot welding, sewing, and adhesive bonding, with a splicing strength of over 80% of the base material, avoiding water leakage or breakage at the joint;

Strong adaptability: Soft texture, able to fit irregular soil surfaces (such as undulating roadbeds, curved embankment slopes), without the need for complex cutting.

5. Economy and environmental friendliness

Cost controllable: Compared to traditional materials such as sand and gravel filter layers and concrete anti-seepage layers, geotextiles have lower material and construction costs, and can reduce the amount of earthwork in the project (such as replacing some sand and gravel with geotextiles and lowering the height of the roadbed);

Environmentally friendly and recyclable: Some geotextiles (such as polypropylene geotextiles) can be recycled and reused, with minimal pollutant emissions during the production process, in line with the concept of green engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy and hydropower engineering

Embankment/reservoir: Lay a composite layer of "geotextile+geomembrane" on the upstream slope of the embankment to prevent water seepage; Laying needle punched geotextile on the backwater slope to filter the sediment in the seepage and avoid pipe surges;

River management: laying woven geotextiles on the river slope, reinforcing the soil and protecting the slope from water erosion, while allowing river water to infiltrate and maintaining the river ecology;

Sewage treatment plant: Composite geotextile is laid at the bottom of sedimentation tanks and leachate treatment tanks to prevent sewage from infiltrating underground and polluting soil and groundwater, while filtering impurities in sludge.

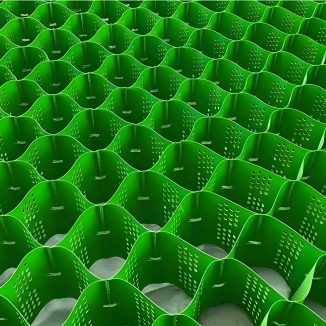

2. Transportation engineering

Highway/railway subgrade: lay woven geotextile at the bottom of the subgrade (between the subgrade and the foundation soil) to isolate different types of soil (such as preventing the mixing of subgrade filling and soft soil foundation); Simultaneously reinforcing the roadbed to reduce roadbed settlement caused by vehicle loads; Lay geotextile on the roadbed slope, drain and prevent rainwater from washing the slope;

Airport runway: Hot melt adhesive geotextile is laid between the base and surface layers of the runway to filter out moisture in the base layer and prevent moisture retention from causing runway cracking;

Tunnel engineering: A needle punched geotextile is laid between the tunnel lining (concrete wall) and the surrounding rock as a "drainage layer" to discharge water leakage from the surrounding rock and prevent the lining from being damaged by water pressure.

3. Construction and municipal engineering

Building foundation: In the treatment of soft soil foundation, geotextile is laid and combined with sand and gravel cushion layer to form a "drainage consolidation system", which accelerates the settlement and stability of the foundation soil;

Landfill site: Install a composite anti-seepage layer of "geotextile+geomembrane" at the bottom and around the landfill site to prevent leachate from seeping into the ground; Laying geotextile on the top of the landfill site to isolate garbage from the covering soil, while filtering rainwater to prevent the loss of covering soil;

Landscape greening: Lay geotextile at the bottom of artificial lakes and landscape water pools to prevent soil infiltration into the water and cause turbidity in the water; Lay geotextile underneath the lawn to isolate the soil from the sand and gravel drainage layer and prevent soil from blocking the drainage channel.

4. Mining and environmental engineering

Mine tailings pond: Geotextile is laid on the dam body and bottom of the tailings pond to filter the sediment in the tailings water and prevent the dam body from surging; Simultaneously isolate tailings from surrounding soil to avoid heavy metal pollution;

Soil remediation: laying composite geotextiles in polluted soil areas as a "barrier layer" to prevent pollutants (such as heavy metals and organic matter) from spreading to surrounding soil and groundwater;

Agricultural engineering: laying geotextile at the bottom of irrigation channels in farmland to reduce channel leakage and improve water resource utilization efficiency; Lay geotextile in the foundation of the greenhouse to isolate soil and sand, and prevent soil compaction.

In short, geotextile, as a multifunctional material in geotechnical engineering, has become an indispensable component of modern engineering construction. Its performance and application scenarios are still expanding, providing important support for the safety, efficiency, and environmental protection of engineering.