Plastic Geocell

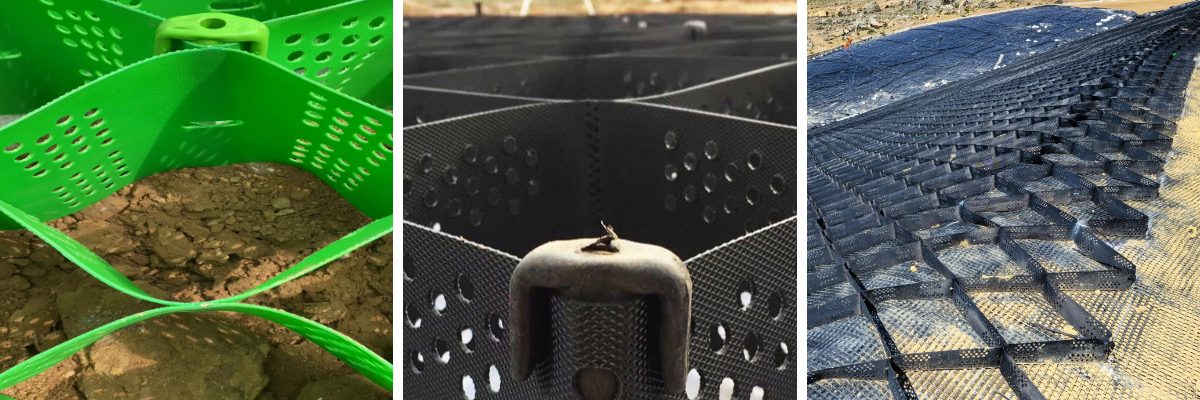

1.Good flexibility: It can be folded for transportation, and stretched into a net during construction, which is convenient for transportation and construction, and can adapt to different site conditions.

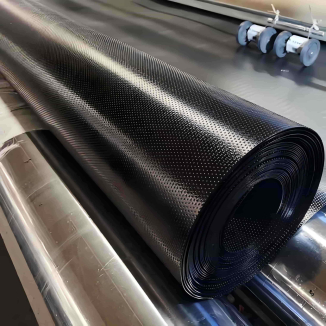

2.Excellent material quality: The material is lightweight, wear-resistant, has stable chemical properties, is resistant to photo-oxidation aging, acids and alkalis, and can maintain stable performance in different soils and harsh environments.

3.Strong lateral restraint: It has a high lateral restraint capacity, can effectively prevent slipping and deformation, enhance the bearing capacity of the subgrade, disperse the load effect, and improve the stability of the foundation.

4.Adjustable size: By changing geometric dimensions such as the height of the geocell and the welding distance, it can meet the specific requirements of different projects.

5.Convenient construction: It is easy to connect, has a fast construction speed, can greatly reduce the construction labor intensity, and shorten the construction period.

Product Introduction:

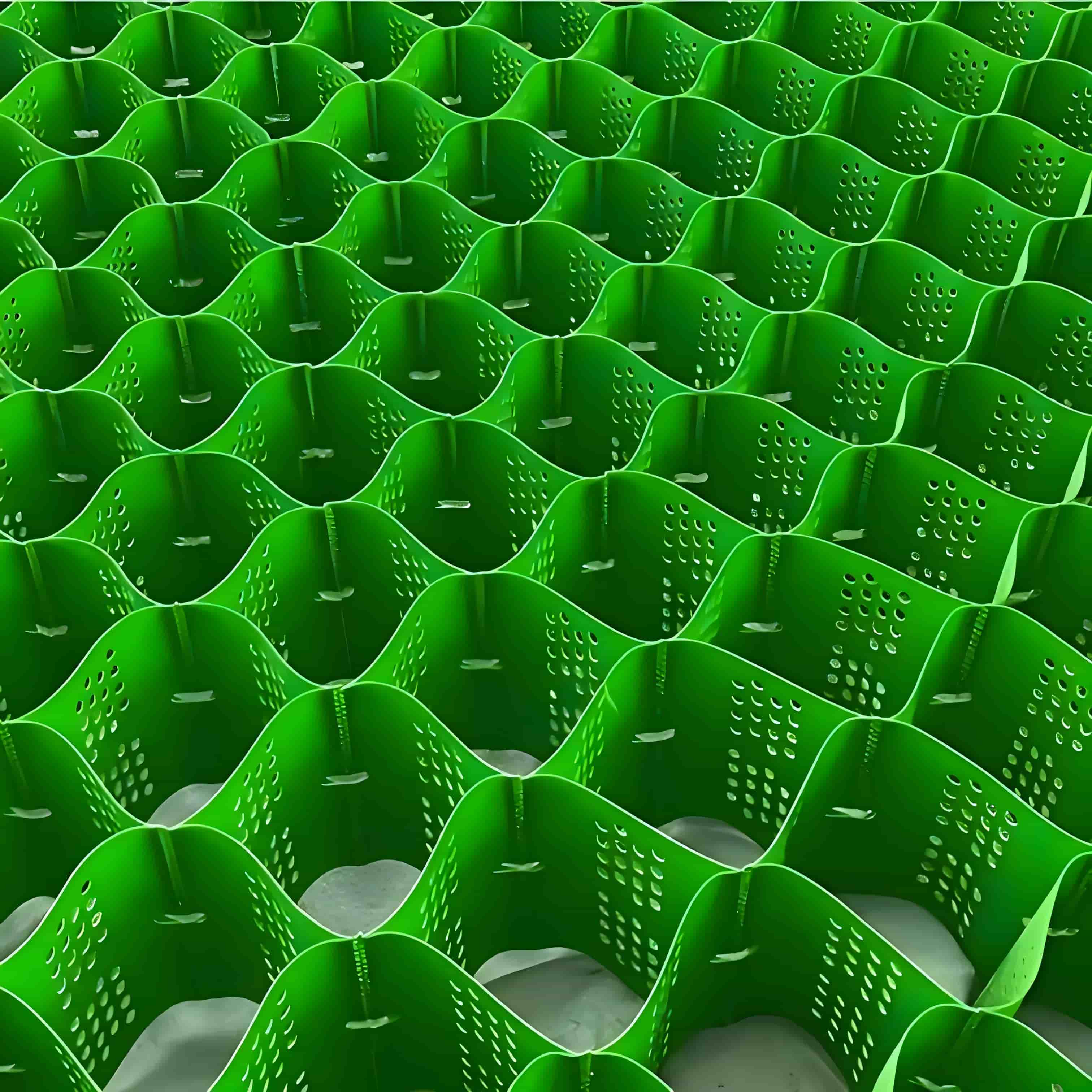

Plastic Geocell is a three-dimensional reticular cell structure formed by welding or riveting high-strength HDPE (high-density polyethylene) or PP (polypropylene) copolymer wide strips with great force.

Principle of action: When external loads act on the surface of the foundation, under the action of concentrated loads, the active zone is compressed and sinks, and the force is decomposed and transmitted to the transition zone on both sides. The transition zone then transfers it to the passive zone, and the passive zone will deform and heave without limitation. The cell walls of the plastic geocell can provide lateral restraint, adjacent cells generate a reaction force, and together with the friction between the filler and the cell walls, a lateral resistance is formed, which suppresses the lateral movement tendency of the transition zone and the passive zone, thereby improving the bearing capacity of the subgrade.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

1.Road Engineering: It is used to stabilize the subgrades of highways and railways. When dealing with the subgrade of semi - filled and semi - excavated sections, the vertical lateral confinement and reinforcement effect can be utilized to solve the problem of uneven settlement. In sandy areas, it can provide lateral confinement to loose fillers, ensuring the stiffness and strength of the subgrade. In permafrost areas, it can ensure the minimum filling height, enabling the filled soil to have high - quality strength and stiffness. It also plays a significant role in the treatment of collapsible loess subgrades.

2.Coastal Protection Engineering: In beach and coastal governance, it can fix the sand beach, prevent coastal erosion, and can also be used in the construction of independent walls, docks, breakwaters, etc., enhancing the structural stability.

3.Water conservancy projects: It can be used for the construction of embankments capable of bearing loads and the treatment of shallow water channels, preventing soil erosion and scouring of riverbanks and riverbeds. It can also be used to build retaining structures, such as hybrid retaining walls to prevent landslides and bear loads.

4.Desert Control Project: In desert areas, it can fix sand dunes, prevent wind and sand erosion, promote vegetation growth, improve the desert ecological environment, and can also be used for the construction of desert roads, improving the stability and durability of the roads.

5.Other fields: It can be used to support pipelines and sewers to ensure their stability. In the construction of sponge cities, it can quickly drain the water in the soil and maintain a certain amount of soil moisture during the dry season to sustain the growth of vegetation.

The core of the application of geocells lies in utilizing their three - dimensional restraint effect to enhance the integrity and bearing capacity of soil. At the same time, it has the characteristics of convenient construction and strong adaptability. Appropriate specifications and models can be selected according to different engineering requirements (such as load, geological conditions, environmental factors) to achieve efficient protection and reinforcement.