Film-Coated Cement Blanket

1.Fast Construction:

No on-site concrete mixing required; simply water after laying to cure, significantly reducing construction time.

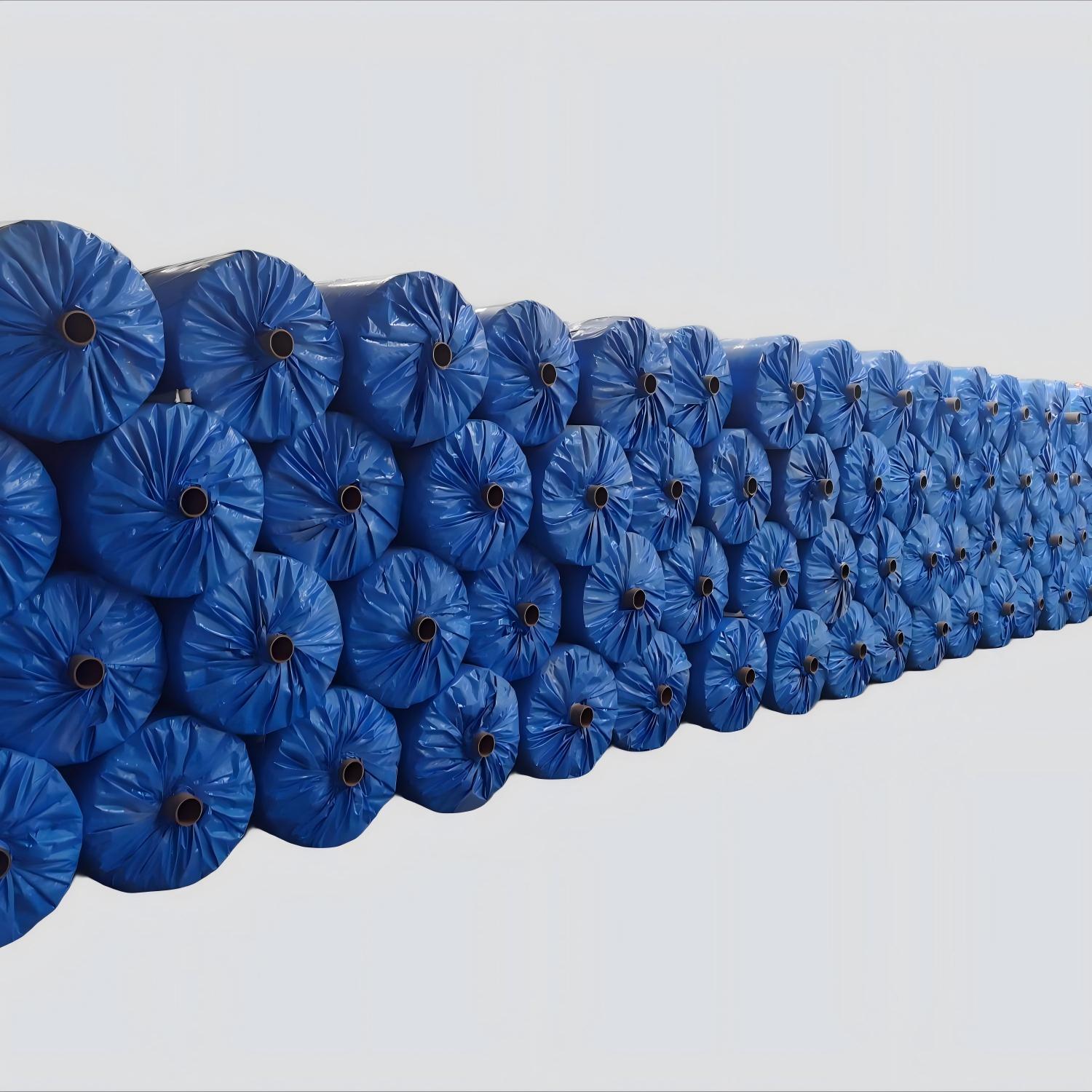

2.Lightweight & Easy to Transport:

Roll-form material, lightweight, and easy to handle and transport.

3.High Adaptability:

Conforms to complex terrains, suitable for slopes and curved surfaces where traditional concrete is difficult to apply.

4.Eco-Friendly & Energy-Efficient:

Reduces material waste, lowers carbon emissions, and requires no heavy machinery.

5.High Durability:

UV-resistant, waterproof, fireproof, and long-lasting.

Product Introduction:

Film-Coated Cement Blanket is a flexible, rapidly hardening composite material consisting of a 3D fibrous matrix (typically fabric) and specially formulated dry-mix concrete. It hardens upon hydration, forming a durable, waterproof, and fire-resistant concrete layer.

Key Features:

1.Flexible & Moldable

Can be rolled or folded before curing to adapt to complex construction environments

Forms a rigid yet tough structure after hardening, combining flexibility with strength

2.Lightweight

Weight per unit area is only 1/10 that of traditional concrete, enabling easy transport and manual installation

3.Customizable

Adjustable thickness (3-10mm), strength, and dimensions to meet diverse engineering needs

4.Low-Maintenance

Requires no special curing after hardening

Excellent crack and seepage resistance, reducing long-term maintenance costs

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

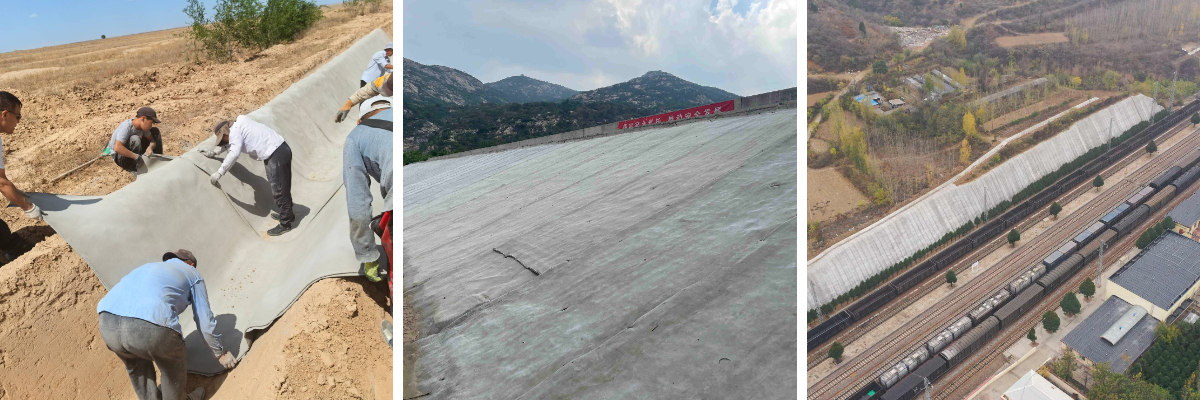

Product Applications:

1.Water Conservancy Projects

Anti-seepage lining for rivers, canals, and ponds, replacing traditional concrete slope protection; emergency reinforcement of reservoir dams.

2.Transportation Engineering

Rapid laying of temporary roads and construction access roads; reinforcement of highway slope protection and drainage ditches; emergency repair of airport runways.

3.Construction Engineering

Waterproof cushion layers for basements and roofs; rapid construction of fence foundations and courtyard floors; replacement of formwork for precast components (such as manholes and cable trenches).

4.Environmental Engineering

Anti-seepage layers for landfills; concrete skeleton support in ecological slope greening, balancing protection and vegetation growth space.

5.Emergency and Disaster Relief

Dike plugging during floods, construction of temporary drainage channels; ground and wall construction for temporary buildings after earthquakes.

Concrete Cloth combines the flexibility of textiles with the strength of concrete, making it a revolutionary engineering material—particularly suited for rapid construction and projects in harsh environments.