Geotechnical Cloth

1.High strength and durability: Made of polymer materials, it has high tensile strength, acid and alkali corrosion resistance, UV resistance, and a service life of up to 10-30 years, reducing maintenance costs in the later stage.

2.Multi functional: It has multiple functions such as filtration, drainage, isolation, reinforcement, and protection, and can meet different engineering needs.

3.Convenient construction: lightweight, easy to cut, no need for complex equipment, high laying efficiency, and can shorten the construction period by 30% -50% compared to traditional materials.

4.Economic and environmental protection: The comprehensive cost is lower than traditional materials, reducing the exploitation of natural resources; Some products use biodegradable materials, which are beneficial for ecological restoration.

5.Strong adaptability: Good flexibility, able to fit complex terrain, widely used in various fields such as water conservancy, transportation, environment, and construction engineering.

Products Introduction:

Geotechnical Cloth is a geosynthetic material with functions such as filtration, drainage, isolation, reinforcement, and protection. It is widely used in fields such as water conservancy, highways, railways, and construction.

The widespread application of geotextiles is characterized by "functional integration", which can flexibly combine functions such as filtration and drainage according to engineering needs. Compared with traditional materials such as sand and clay, geotextiles have the advantages of high construction efficiency, cost-effectiveness, and ecological friendliness, and have become a key material for solving geotechnical problems in modern engineering.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

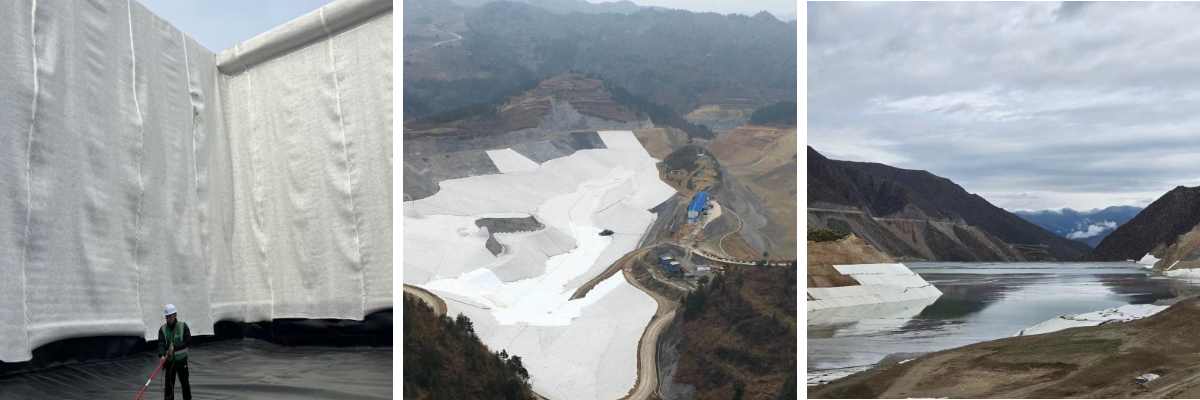

1.Embankment and River Channel: Used as a filter layer for the anti-seepage layer of the embankment, preventing soil particle loss and drainage, and preventing leakage; Laying on slopes in river regulation to protect soil from water erosion and reduce soil erosion.

2.Reservoir and irrigation area: used as reinforcement material to enhance soil stability during reservoir dam reinforcement; Laying at the bottom of irrigation channels can isolate different soil layers, prevent sediment from mixing into water bodies, and ensure water delivery efficiency.

3.Highways and railways: During roadbed construction, it is laid between the foundation and the filling material to isolate different soil layers and drain water to prevent roadbed settlement; Strengthening the pavement base can enhance tensile strength and reduce the occurrence of cracks; In tunnel engineering, it is used for drainage systems to divert groundwater and avoid structural seepage.

4.Airports and ports: Geotextile is laid on the foundation of airport runways to enhance their load-bearing capacity and cope with aircraft takeoff and landing loads; In the protection of the bank slope of the port terminal, its protective function is used to resist wave erosion and protect the stability of the bank slope.

5.Landfill site: As the core material of the anti-seepage system, it is combined with HDPE film to block the leakage of pollutants. At the same time, the geotextile layer of the drainage layer timely discharges the leachate to prevent water accumulation in the landfill site; After closure, it can be used for vegetation layer isolation to promote ecological restoration.

6.Sewage treatment and mining: laying aeration tanks and sedimentation tanks at the bottom of sewage treatment plants to assist in drainage and isolation; By reinforcing and draining the tailings dam, the collapse of the dam body is prevented, and the tailings water is filtered to reduce environmental pollution.

7.Municipal greening: used as a drainage layer in urban roof greening to prevent water accumulation from damaging the roof structure; In ecological slope protection engineering, biodegradable geotextile provides a carrier for vegetation growth, achieving the combination of slope stability and greening.

8.Basement and roof: Geotextile is laid on the basement floor and exterior walls as an anti-seepage layer to prevent groundwater infiltration; Used for drainage in roof waterproofing systems, combined with waterproof layers to reduce the risk of roof leakage.

9.Foundation treatment: When reinforcing weak foundations, geotextiles increase the bearing capacity of the foundation through reinforcement, reducing building settlement; Used for slope support in excavation of foundation pits to enhance soil stability.

In short, Geotechnical Cloth has become an indispensable material in modern civil engineering due to its excellent performance, convenient construction, and wide applicability. It has significant advantages in improving engineering quality, reducing costs, and protecting the environment.