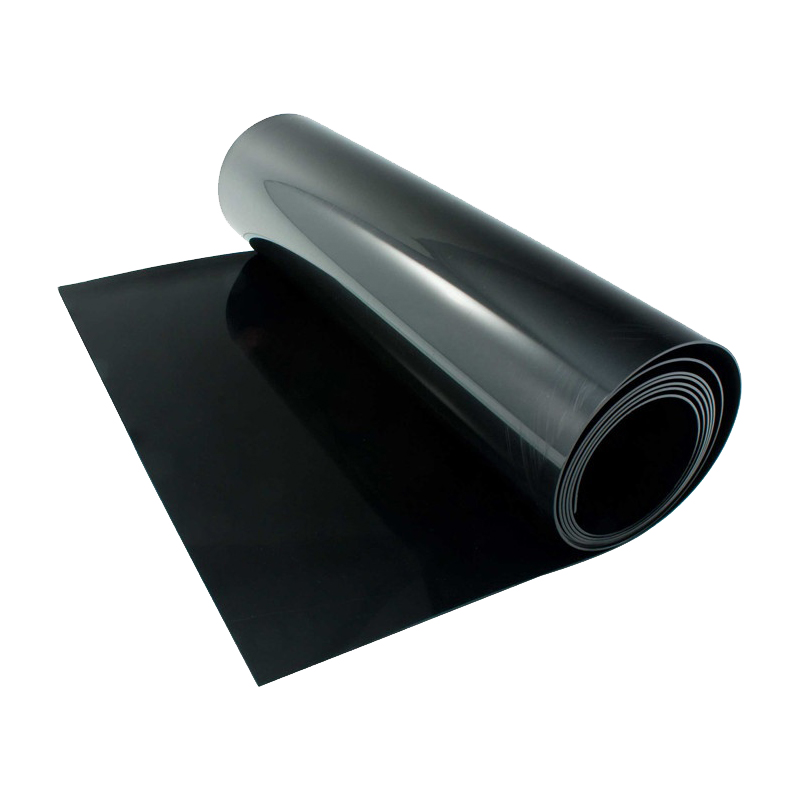

High Density Polyethylene Liner

1.Ultimate Waterproofing: Its high-density molecular structure makes it virtually impermeable, effectively preventing the leakage of liquids and harmful substances, ensuring long-lasting waterproofing.

2.Strong and Durable: High tensile strength and puncture resistance; withstands external impacts and soil friction, making it resistant to damage.

3.Weather and Corrosion Resistant: Resistant to UV aging, acids, alkalis, and salt spray corrosion; long service life (15-25 years) even in complex environments.

4.Construction Compatibility: Flexible and easy to lay; can be applied to irregular surfaces; strong welded joints; suitable for large-scale engineering projects.

Products Introduction

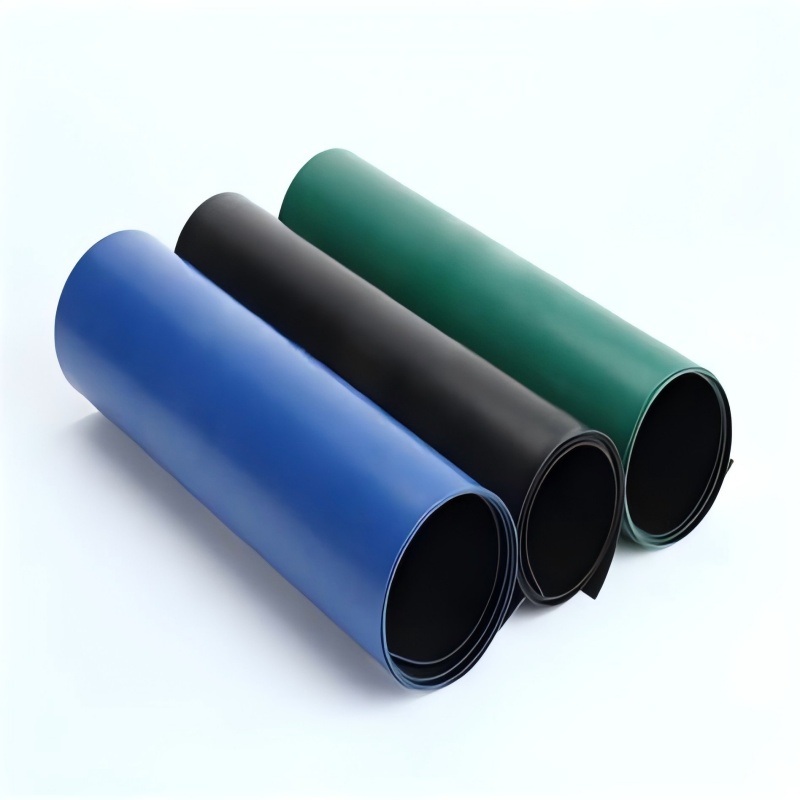

High Density Polyethylene Liner (HDPE anti-seepage film) is a homogeneous anti-seepage material made of high-quality HDPE resin through blow molding or rolling processes, with a thickness range of 0.5-3mm. Its core positioning is "the long-term barrier core of strict anti-seepage engineering". By virtue of the unique linear molecular arrangement structure of HDPE material, it achieves the seepage control effect of "zero permeability level". At the same time, it has the characteristics of high strength, weather resistance, corrosion resistance, aging resistance, etc. It is mainly used to solve the key problems of "high-risk leakage, migration of harmful substances, efficient utilization of water resources" in the fields of water conservancy, environmental protection, mining, etc., and provides safe, reliable and long-life solutions for large-scale and demanding seepage control projects.

Product Features

1. Zero permeability grade anti-seepage, top-notch barrier performance

The dense molecular chain structure formed by HDPE resin results in a product permeability coefficient of ≤ 1 × 10 ⁻¹³ cm/s, far below the international anti-seepage standard (≤ 1 × 10 ⁻¹¹ cm/s), achieving "almost absolute" barrier to various liquids such as water, sewage, and chemicals; The homogeneous thickness design ensures that the membrane body has no weak points, and when combined with hot air welding or extrusion welding processes, the welding seam strength is ≥ 85% of the substrate strength, forming a complete and seamless anti-seepage system that completely eliminates the risk of leakage and is suitable for high pollution and high leakage risk scenarios.

2. Superb mechanical performance and outstanding resistance to damage

Tensile strength ≥ 20MPa, fracture elongation ≥ 500%, able to adapt to deformation caused by uneven settlement and temperature changes of the foundation without rupture; Anti puncture strength ≥ 400N, capable of withstanding crushed stone compaction, mechanical impact, and plant root puncture during construction; The tear resistance strength is ≥ 80N, reducing the probability of damage during construction and use, providing a "high-strength protective barrier" for the project, and adapting to heavy-duty and complex construction environments.

3. Weather resistant and corrosion-resistant in all environments, with a long lifespan

The raw materials have undergone triple stabilization treatment of anti ultraviolet (UV), anti oxygen and anti-aging, and the performance degradation is ≤ 15% after 10 years of outdoor exposure. The service life can reach 20-30 years due to isolation of light and oxygen during underground use; The acid and alkali resistance range covers pH values of 1-14, and is resistant to strong acids, strong alkalis, salt spray, organic solvents, and industrial waste liquids. It can still work stably in extreme environments such as coastal areas, mines, and chemical industries, greatly reducing the cost of replacement and maintenance in the later stage.

4. Flexible and adaptable, efficient and standardized construction

Although it is a high-density material, it still has good flexibility and can fit curved slopes, irregular potholes, and complex structural corners without blind spots for seepage prevention; Single roll specifications support customization (with a maximum width of 12m and any length), reducing the number of joint seams and improving construction efficiency; Automated welding equipment is used, with a welding speed of 3-8m/min and manual assistance to complete the laying process. The construction efficiency reaches 300-500 ㎡/day, and the welding quality can be verified through methods such as air pressure testing and vacuum testing, in compliance with commercial engineering standards.

5. Environmental compliance, safety and reliability

Using food grade HDPE resin, non-toxic, odorless, and free of heavy metal precipitation, it meets domestic and international environmental and engineering standards such as GB/T 17643-2011 and ASTM D4397, and is suitable for scenarios with extremely high environmental requirements such as drinking water tanks and water plants; Recyclable, the waste can be reprocessed after treatment, in line with the concept of green engineering and sustainable development, reducing environmental load.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications

1. Environmental protection and pollution prevention engineering

Landfill site: As the main anti-seepage liner and sealing cover layer for domestic and industrial waste landfill sites, it prevents leachate from infiltrating into soil and groundwater, and forms a "composite anti-seepage system" with geotextile protection layer, suitable for large-scale landfill projects.

Hazardous waste disposal site: used for anti-seepage of medical waste and chemical hazardous waste disposal sites, blocking the migration of toxic and harmful substances, protecting the safety of surrounding soil and groundwater, and adapting to environmental protection hazardous waste treatment projects.

2. Water conservancy and water engineering

Large reservoirs/lakes: laid at the bottom of the reservoir, on the upstream slope of the dam, or in artificial lakes to prevent seepage, reduce water resource leakage, maintain water level stability, and adapt to medium-sized reservoir reinforcement and artificial storage lake construction projects.

Water transmission pipeline/channel: used for interface anti-seepage of long-distance water transmission pipelines and slope and bottom lining of large water transmission channels to prevent water resource loss during the water transmission process, suitable for cross basin water transfer projects.

3. Mining and Industrial Engineering

Mine tailings pond: As the anti-seepage lining of the tailings pond dam body and the anti-seepage layer of the leachate collection pool, it prevents tailings wastewater from polluting soil and groundwater, enhances the stability of the dam body, and is suitable for large-scale metal and non-metal tailings pond projects.

Chemical Industry Park: Used for anti-seepage of raw material storage tank areas, wastewater treatment tanks, and reaction tanks in chemical enterprises, blocking chemical leakage and wastewater infiltration, and adapting to environmental protection anti-seepage projects in chemical industry parks.

4. Construction and Municipal Engineering

Underground pipe gallery/tunnel: laid on the outer wall and bottom plate of the underground comprehensive pipe gallery and tunnel, forming a waterproof and anti-seepage barrier, resisting soil water and groundwater erosion, protecting the pipe gallery structure and internal pipelines, and adapting to urban underground pipe gallery construction.

Roof greening/large water features: used as anti-seepage layers for roof greening of urban landmark buildings and landscape water feature liners for large commercial complexes to prevent water seepage from damaging building structures, suitable for high-end building greening and landscape engineering.

High Density Polyethylene Liner, with its core advantages of "zero permeability anti-seepage, super strong damage resistance and durability, full environmental weather resistance, and standardized environmental protection and long-term effectiveness", accurately solves the core pain points of "high leakage risk, poor environmental adaptability, and long service life requirements" in strict anti-seepage engineering, and is the "safety cornerstone" of large-scale commercial anti-seepage projects.